How Piezo Direct Can Be Your Piezo Crystal Manufacturer

Piezoelectricity is the property that is found in piezoelectric materials like quartz and barium titanate. This was first discovered in 1880 by two French physicists. Piezoelectric materials can produce a mechanical stress when an electrical charge is applied to it. The amazing thing is that this process can also be reversed, meaning the material can produce an electrical charge if mechanical stress is applied.

The first time someone tried making piezoelectric ceramic devices took place during World War I. Two French scientists wanted to create a perfect piezoelectric ceramic ultrasonic submarine detector to help their country, but they didn’t finish this application until after the war ended.The success of this piezoelectric transducer led to the intense research and development of piezoelectric ceramic devices. During the period after the first World War, piezoelectric ceramic products like microphones, accelerometers, signal filters, etc. were invented.

During the 2nd World War, the U.S, Japan and the Soviet Union discovered that certain ceramic materials exhibited dielectric constants up to 100 times higher than common cut crystals. The discovery of easily manufactured piezoelectric ceramics led a revival of intense research and development of piezoelectric sensors, piezoelectric transducers, piezo actuators. Powerful sonars, ceramic phono cartridges, ceramic audio tone transducers ,etc., were all developed during this period. During the 20th century, a record number of patents have been granted by the U.S Patent Office annually showing that the world is becoming more aware of the possibilities of piezoelectric ceramics. As the applications of piezoelectric ceramics grows, piezo crystal manufacturers are challenged to meet the demand for increasingly complex and innovative piezo elements.

As a piezoceramic manufacturer, Piezo Direct is proud to offer a completely custom piezoelectric crystal manufacturing process. If you have specific requirements for piezo actuators, piezoelectric ceramic sensors, and piezoelectric transducers. Piezoelectric ceramic sensors, actuators, and transducers are utilized across many industries, including industrial machinery, commercial household items, automotive and aerospace functions, IOT, ultrasonic generation, and even underwater sonar applications. For specific custom piezoceramic design and support, you can trust Piezo Direct as your piezoelectric ceramic manufacturer. The entire process is streamlined and efficient, with ongoing technical support from start to finish. Learn more about the custom piezo manufacturing process of piezoelectric ceramic sensors, actuators, and transducers below.

Piezoceramic Products by Piezo Direct

Piezoelectric Actuators

Piezoelectric Ceramic Sensor

Piezoelectric Transducer

Multilayer Stack Piezo Actuators

Multilayer stack piezo actuators consist of stacks of piezo elements that expand when an electrical charge is applied. Multilayer stacks are commonly utilized for precision machinery and control in industrial, medical, aerospace, and automotive industries. Learn more about piezo multilayer actuators here.

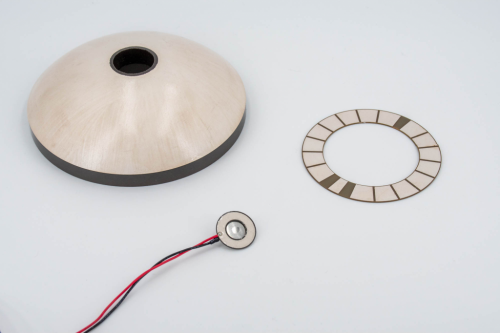

Piezoelectric Disc

Piezoelectric discs are circular piezo elements often found in automotive functions, sound production and amplification, liquid and fluid level measurement, and ultrasonic applications. Learn more about piezo discs here.

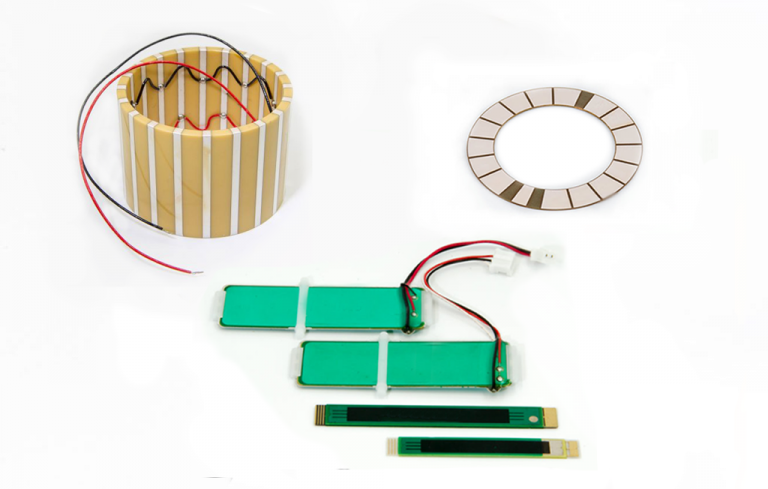

Piezoelectric Bending Strip

Piezo strip benders are thin pieces of active piezoelectric material connected to a passive layer. Strip piezo elements are commonly utilized in valve and pump controls, accelerometers, sound production, touch switches/controls, and fine machinery. Learn more about strip piezos here.

Piezoelectric Ring

Piezoelectric rings are often used in multilayer stack piezo actuators to produce linear movement. Piezo rings are often found in ultrasonic applications, nanopositioning, microscopy, and precision machining. Learn more about piezo rings here.

Piezoelectric Tube

Tube piezo actuators can generate axial displacement (changes in length) or radial displacement (changes in diameters). Tube piezoelectric actuators are often utilized for flow and level measurements and adjustments, scanning microscopy, and microdosing, commonly found in the industrial and commercial industries. Learn more about piezo tubes here.

Piezoelectric Bimorph

Bimorph piezoelectric actuators consist of two active piezoelectric layers bonded to a passive metal substrate or bonded directly together. This causes a bending motion that can either perform a desired task or generate a readable electrical output. Learn more about piezo bimorphs here.

Piezoelectric Unimorph

Unimorph piezoelectric actuators consist of one active piezoelectric layer often bonded to a passive metal substrate. Unimorph actuators deform in a single direction when activated by an electrical input and translate it into a mechanical output.

Piezoelectric Plates and Blocks

Piezoelectric actuators shaped as plates and blocks can be engineered into any shape. Piezo block actuators are used for high power generation and applications. Learn more about piezo plates and blocks here.

Your Trusted Piezo Supplier for High-Quality Piezoelectric Products

When it comes to sourcing high-quality piezoelectric components, Piezo Direct is your trusted piezo supplier. As one of the leading piezoceramic manufacturers, we are committed to delivering top-tier components for your projects.

Reliable Piezo Suppliers:

As a piezo supplier, we understand the importance of reliability and performance in the solutions we offer. Piezo Direct is your one-stop destination for all your piezoelectric needs.

Wide Range of Products:

Our catalog features an extensive range of piezoelectric products suitable for diverse applications. From custom components to specialized solutions, we have the expertise and manufacturing capabilities to deliver products that meet your specifications.

At Piezo Direct, we are dedicated to providing high-quality piezo elements, piezo stack actuators, ultrasonic transducers, piezo ceramic rings, and other piezoelectric products to support your projects and innovations. Explore our website to find the perfect solutions for your unique requirements.

Piezoelectric Ceramic Manufacturer Process

The process for manufacturing piezoceramics is very similar to the process to make any other ceramic products like plates and bowls. Different piezoelectric ceramics processes have different steps, but they all share the same common steps.

- The first step is to select the highest grade raw material (PZT powder).

- Once the material is selected, it is weighed and then transferred to the mills.

- The ingredients are then wet-milled together with the proper mixtures.

- Afterwards, the mill is discharged, and the product is dried and prepared for calcining.

- The calcining operation takes place at about 1000°C, where the piezoelectric ceramic is made.

- After calcining, the powder is returned to the mill and to prepare the material for the addition of binder.

- Lastly, the binder-containing slurry, is fed to a spray dryer, where water is evaporated.

Why Choose Piezo Direct

When it comes to selecting a piezo supplier, Piezo Direct stands out as one of the highest-rated options in the industry. With decades of experience and a reputation for excellence, we have earned the trust of numerous clients, ranging from small businesses to multinational corporations. Our commitment to quality, reliability, and customer satisfaction sets us apart in the competitive market of piezoelectric components. Whether you require standard components or custom solutions, Piezo Direct delivers unparalleled expertise and support at every step of the process. With a comprehensive catalog of top-tier products and a dedication to meeting the unique needs of each client, we are proud to be the preferred choice for discerning customers seeking high-quality piezoelectric solutions.

Finding the right piezoelectric crystal manufacturer to partner with is a key step in the success of your piezoelectric product or piezo element. Piezo Direct has been a trusted piezo company for decades, partnering with some of the world’s largest brands to create innovative commercial, medical, aerospace, and industrial custom piezo components. For more information on how to make Piezo Direct your piezo crystal manufacturer, please contact us below.