Applications of Piezoelectric Ceramics

Piezoelectric manufacturers like us provide various types of piezoelectric ceramics for different market sectors.

Some of our Piezoelectric ceramic applications include:

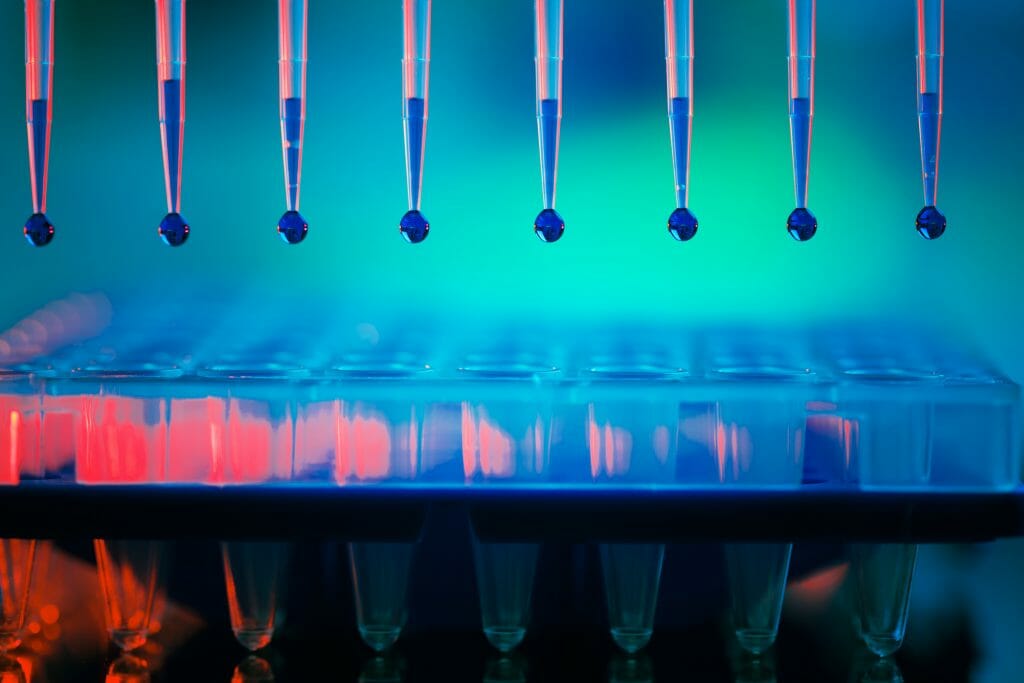

- Medical – Bone conduction hearing aids, Ultrasonic surgical instruments, Micro- and nano-dosing equipment

- Communications – Antennas, Sensors

- Optics – Fiber positioning, turntable lasers

- Automotive – Knock sensors, Fuel injectors

- Commercial – Alarms, Buzzers, Printers

What Are Piezoelectric Ceramics?

Piezoelectric ceramics are a class of advanced materials known for their unique ability to convert mechanical energy into electrical energy and vice versa. These ceramics, often composed of compounds like Lead Zirconate Titanate (PZT), exhibit the piezoelectric effect, where an applied mechanical stress induces an electrical charge across the material, and conversely, an applied electrical field leads to mechanical deformation. This remarkable property makes piezoelectric ceramics invaluable in a wide range of applications, including sensors, actuators, transducers, and energy harvesting devices. Their precision in converting energy between mechanical and electrical forms makes them essential for various industries, from medical imaging and industrial automation to consumer electronics and aerospace. The adaptability of piezoelectric ceramics to generate controlled vibrations, manipulate precise movements, and convert energy in diverse environments underscores their importance in modern technology and innovation.

Explore the diverse applications of piezoelectric ceramics and piezoceramic materials on Piezo Direct’s informative page. From medical devices to industrial sensors and beyond, piezoelectric ceramics play a pivotal role in numerous cutting-edge technologies. Delve into the wide-ranging applications, understanding how these materials contribute to advancements in ultrasound imaging, energy harvesting, and precision measurement.

More About Piezoelectric Ceramics

As the technology for piezoelectricity advances, there will be more and more products that use piezoelectric ceramics. One of the best examples is the future of eco-friendly energy. Let’s say you make a road with piezoelectric ceramic elements, so anyone who walks on it will generate kinetic energy. This energy can then be stored and used for a variety of purposes. This process, known as energy harvesting, is just one of the few ways piezoelectric ceramics can transform our daily energy consumption.

This utilization of piezoelectric ceramics has already been tested in multiple places. For example, in Brazil, there is a special soccer field which converts the energy from players running on the field along with solar panels to power LED lights at night. Just imagine applying this technology to roads in densely populated areas like San Francisco. The energy generated from human traffic could be used to power the city. Piezoelectric ceramics have massive implications for energy harvesting.

The precision and accuracy afforded by piezoelectric ceramics is also highly valued in the medical industry. Surgical equipment, dosing machines, transfusion machines, sensors, and measurement tools all can utilize piezoelectric ceramic elements. Laser eye surgery, or LASIK, is a well known surgery that heavily relies on the precision movements provided by piezoelectric ceramics to position a laser around the eyeball. Other implementations of piezoelectric ceramics in medical applications include nebulizers, pumps and valves in ventilators, nanodosing and dispensing machinery, and even the exploration of needle-free shots.

Industrial, medical, automotive, aerospace, and commercial industries continue to increase their use of piezoelectric ceramics in a wide range of applications. Many well known companies have launched piezoelectric ceramics into space for a variety of applications, from positioning satellites to gathering data on materials in space through sensors. Here are just a few other examples of applications that utilize piezoelectric ceramics. To view more specific applications, please read about our fully customizable piezo actuators, piezoelectric sensors, and piezoelectric transducers.

Piezoelectric Actuators

Piezoelectric Ceramic Sensor

Piezoelectric Transducer

Multilayer Stack Piezo Actuators

Multilayer stack piezo actuators consist of stacks of piezo elements that expand when an electrical charge is applied. Multilayer stacks are commonly utilized for precision machinery and control in industrial, medical, aerospace, and automotive industries. Learn more about piezo multilayer actuators here.

Piezoelectric Disc

Piezoelectric discs are circular piezo elements often found in automotive functions, sound production and amplification, liquid and fluid level measurement, and ultrasonic applications. Learn more about piezo discs here.

Piezoelectric Bending Strip

Piezo strip benders are thin pieces of active piezoelectric material connected to a passive layer. Strip piezo elements are commonly utilized in valve and pump controls, accelerometers, sound production, touch switches/controls, and fine machinery. Learn more about strip piezos here.

Piezoelectric Ring

Piezoelectric rings are often used in multilayer stack piezo actuators to produce linear movement. Piezo rings are often found in ultrasonic applications, nanopositioning, microscopy, and precision machining. Learn more about piezo rings here.

Piezoelectric Tube

Tube piezo actuators can generate axial displacement (changes in length) or radial displacement (changes in diameters). Tube piezoelectric actuators are often utilized for flow and level measurements and adjustments, scanning microscopy, and microdosing, commonly found in the industrial and commercial industries. Learn more about piezo tubes here.

Piezoelectric Bimorph

Bimorph piezoelectric actuators consist of two active piezoelectric layers bonded to a passive metal substrate or bonded directly together. This causes a bending motion that can either perform a desired task or generate a readable electrical output. Learn more about piezo bimorphs here.

Piezoelectric Unimorph

Unimorph piezoelectric actuators consist of one active piezoelectric layer often bonded to a passive metal substrate. Unimorph actuators deform in a single direction when activated by an electrical input and translate it into a mechanical output.

Piezoelectric Plates and Blocks

Piezoelectric actuators shaped as plates and blocks can be engineered into any shape. Piezo block actuators are used for high power generation and applications. Learn more about piezo plates and blocks here.