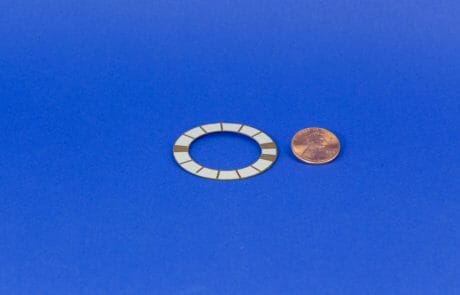

Piezoelectric Rings

Piezo rings have a variety of functions and are suitable for numerous applications. When a voltage is applied, the piezoelectric ring deforms and/or vibrates. A DC voltage will cause the piezoelectric ring to deform, while an AC voltage will cause the piezo ring to vibrate allowing the ring to function as a piezo actuator. Conversely, if mechanical strain (vibration or pressure) is introduced to the piezoelectric ring, it generates a current. The latter effect allows the piezo ring to function as a piezoelectric sensor. Both these principles can be used interchangeably in ring piezoelectric transducers.

Piezo rings are small, versatile, and durable. They generate high power and are stable in extreme environments. Piezoelectric rings are often assembled into different shapes, stacks, and configurations to achieve the desired result, be it ultrasonic cleaning or nanopositioning.

Applications

- Ultrasonic cleaners

- Ultrasonic scalers

- Ultrasonic welders

- Optics and laser medical technology

- Microscopy and nanopositioning

- Shock and vibration measurement

Precision and Power: Piezo Ceramic Rings

Piezo ceramic rings are remarkable components known for their precision and power. At Piezo Direct, we offer a range of piezo ring actuators designed to meet your performance requirements.

Piezo Ceramic Rings:

Piezo ceramic rings, also known as ring actuators, are components that can produce axial motion when voltage is applied. Their compact size and high displacement make them ideal for applications such as valve control, nano-positioning, and more.

Customization Options:

At Piezo Direct, we understand that every application is unique. That’s why we offer customization options for our piezo ceramic rings. Whether you need a specific size, shape, or performance characteristics, we can work with you to create a tailored solution that meets your exact requirements.

Piezo Direct offers a variety of piezo rings. Shape, finish, material, dimensions, and performance levels can all be customized! Piezo Direct’s rings are suitable for numerous applications. Unsure what you need? Contact us! Piezo Direct is more than happy to work with you to design a custom piezoelectric ring to meet your application requirements.

- Ring Actuators

- Ring Sensors

- Ring Transducers

Ring Piezo Actuators

Detailed Mechanics

Ring piezo actuators are a type of piezoelectric actuator that is shaped like a ring. They are often stacked and used in circular multilayer stack actuators. Piezoelectric rings are made of a material that expands or contracts when an electric voltage is applied. This makes them ideal for use in a variety of applications that require high force, quick response, and high precision.

Detailed Mechanics of Ring Piezo Actuators

- Stacked Design: Ring piezo actuators are often stacked in a multilayer configuration to increase their force output and displacement.

- Central Hole: The hole in the center of the piezo ring allows for connections with outside wires or other components.

- Longitudinal and Shear Displacement: Depending on the construction of the piezo ring, it can achieve different forms of displacement, including longitudinal (lengthwise) and shear (sideways).

- Harsh Environment Performance: Piezoelectric ring actuators are specially designed to perform well in harsh environments. They are resistant to shock, vibration, and temperature extremes.

Applications of Ring Piezo Actuators

- Ultrasonic Vibrations: Piezo ring actuators are often used to generate ultrasonic vibrations. This makes them ideal for use in ultrasonic scalers for dental applications, ultrasonic welders, and ultrasonic cleaning equipment.

- Nanopositioning: Piezo ring actuators are also used in nanopositioning applications, such as optics, laser, microscopy, and precision machining. Their small size and high precision make them ideal for these delicate tasks.

- Medical Devices: Piezo ring actuators are used in drug delivery systems, surgical robots, and more.

Benefits of Using Ring Piezo Actuators

- High Force and Precision: Ring piezo actuators can generate high forces and displacements with high precision.

- Quick Response: Piezo actuators have a very fast response time, making them ideal for applications that require quick movements.

- Small Size and Light Weight: Piezo ring actuators are small and lightweight, making them easy to integrate into compact devices.

- Long Lifespan: Piezoelectric rings are very durable and can last for many years without needing to be replaced.

- Versatility: Piezo ring actuators are used in a wide variety of applications, making them a versatile tool for engineers and designers.

Conclusion

Ring piezo actuators are a powerful and versatile type of actuator that can be used in a wide variety of applications. Their high force, quick response, and high precision make them great for tasks that require precision and control. If you are looking for an actuator that can meet your demanding needs, then a ring piezo actuator may be the perfect solution.

Ring Piezo Sensors

Detailed Mechanics

Ring piezo sensors, with their donut-shaped design, boast unique capabilities in converting mechanical energy into electrical signals. These versatile sensors excel in measuring distance, fluid levels, air/liquid flow, and even generating power from ultrasonic vibrations. Let’s delve deeper into their intricate mechanics and explore the diverse applications they power.

Detailed Mechanics:

- Piezoelectric Effect: At the heart of a ring piezo sensor lies the piezoelectric effect. This inherent property in certain materials, like lead zirconate titanate (PZT), allows them to generate electricity when subjected to mechanical stress (pressure, vibration). In our ring sensor, deformations or vibrations cause the PZT element to produce a proportional electrical output.

- Ultrasonic Sensitivity: These sensors can act as miniature microphones, picking up ultrasonic vibrations that are inaudible to humans. By converting these high-frequency sound waves into electrical signals, they enable various applications like object detection and flow measurement.

- Transducer Synergy: Ring piezo sensors often work in tandem with piezoelectric actuators in transducer assemblies. The sensor detects mechanical changes induced by the actuator, providing feedback for precise control and monitoring.

Applications:

- Distance Measurement: By emitting and receiving ultrasonic pulses, ring piezo sensors determine the distance to objects with high accuracy. This finds applications in robotics, proximity sensors, and even self-parking cars.

- Fluid Level Monitoring: Immersed in liquids, ring piezo sensors detect changes in fluid level based on the pressure variations they experience. This is crucial for monitoring fuel tanks, reservoirs, and industrial processes.

- Air/Liquid Flow Measurement: Similar to fluid levels, ring sensors can measure the flow rate of air or liquids in pipes or ducts. This data is valuable for optimizing ventilation systems, monitoring industrial processes, and even tracking athletic performance (think: measuring wind speed for runners).

- Vibration Monitoring: Sensitive to even the slightest tremors, ring piezo sensors are used in accelerometers and vibration monitoring systems. This finds applications in aerospace for engine health monitoring, in manufacturing for machinery diagnostics, and even in earthquake early warning systems.

- Data Acquisition: In complex systems like aircraft or manufacturing lines, ring piezo sensors feed real-time vibration data into data acquisition systems. This data is crucial for optimizing performance, preventing failures, and ensuring overall system health.

Beyond the Applications:

The inherent advantages of ring piezo sensors – their compact size, high sensitivity, and wide operating range – make them a valuable tool across various industries. We can expect more inventive applications for these versatile sensors in the future.

Ring Piezo Transducers

Detailed Mechanics

Ring piezo transducers, the versatile wizards of the transducer world, seamlessly convert between electrical and mechanical energy. Imagine a device that can act as both a microphone and a speaker, all while wielding the power of ultrasound – that’s the magic of a ring piezo transducer!

Detailed Mechanics:

- Double Duty with Piezo Power: These wonder rings are made of piezoelectric materials like lead zirconate titanate (PZT). This special property allows them to generate electricity when squeezed or vibrated (direct piezoelectric effect), and conversely, produce vibrations when given an electric jolt (converse piezoelectric effect). Talk about a two-way street!

- Ring Shape Advantage: The donut-shaped design offers unique benefits. The central hole allows for easy mounting and integration into various applications. Additionally, the circular geometry distributes forces evenly, leading to increased durability and stability.

- Stacking for Superpowers: Combining multiple ring transducers in a “stack” configuration amplifies their output, generating even more powerful mechanical vibrations or electrical signals. This makes them ideal for high-intensity applications like ultrasonic cleaning and welding.

- Sonic Savvy: Ring transducers excel in the realm of ultrasound. They can generate high-frequency sound waves that are inaudible to humans but incredibly powerful for various tasks. Think cleaning dirt at a microscopic level, welding plastics without heat, or even imaging your internal organs!

Applications:

- Ultrasonic Cleaning Kings: From jewelry to medical instruments, ring transducers power ultrasonic cleaners that remove dirt and grime with ease. The high-frequency vibrations create microscopic bubbles that burst, dislodging even the most stubborn residues.

- Sonic Surgeons: In medical applications, ring transducers are the silent heroes of ultrasound imaging. They send and receive ultrasonic waves to generate detailed images of internal organs and tissues, aiding in diagnosis and treatment.

- Welding Without the Torch: Forget the fiery flames! Ring transducers can weld plastics and other materials using ultrasonic vibrations. The intense friction generated at the weld point melts the materials, creating a strong bond without heat damage.

- Humidifying Helpers: Feeling parched? Ring transducers can come to the rescue! They power ultrasonic humidifiers that vibrate to break water droplets into a fine mist, adding moisture to dry air and keeping you comfortable.

- Beyond the Obvious: The possibilities are endless! Ring transducers are finding their way into fuel injection systems, atomizers for perfumes and fragrances, and even haptic feedback devices for smartphones.

A Final Note:

Ring piezo transducers are marvels of engineering, packing versatility and power into a compact, donut-shaped package. Their ability to seamlessly convert between electrical and mechanical energy, coupled with their mastery of ultrasound, makes them invaluable across various industries. So, the next time you hear the faint hum of an ultrasonic cleaner or marvel at a detailed ultrasound image, remember the unsung heroes behind it all – the ring piezo transducers, the sonic powerhouses silently shaping our world.