Introduction to Piezo Atomizers

Piezo Direct stands at the forefront of innovation, specializing in the development and production of cutting-edge piezo atomizers. Our commitment lies in harnessing the remarkable properties of piezoelectric technology to create ultrasonic marvels capable of precisely vibrating and atomizing liquids.

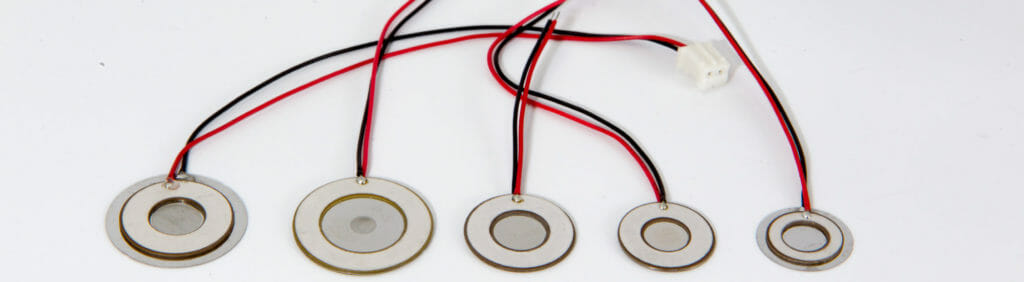

At the core of our technology lies the single-chip atomizer, a testament to precision engineering and efficiency. Designed with a focus on versatility, these atomizers cater to a broad spectrum of applications, making them the ideal choice for industries ranging from healthcare to agriculture.

Key Features of our Single-Chip Atomizer

- Metal Mesh Mastery: Our atomizers leverage the power of meticulously crafted metal mesh technology. The intricate design utilizes the sides of the mesh to achieve exceptional liquid atomization, ensuring optimal performance.

- Fine-tuned Efficiency: Optimal Driving Voltage (50 to 70Vp-p): Engineered for peak efficiency, our atomizers operate within a precise optimal driving voltage range of 50 to 70Vp-p. This meticulous calibration guarantees flawless operation, maximizing the potential of your application.

- Frequency Finesse: Adaptable Signal Frequency: Our atomizers demonstrate remarkable adaptability, seamlessly working with a sine signal frequency tailored to the specific requirements of each application. This ensures perfect harmony between the driving force and the atomizer, leading to superior results.

- Environmental Adaptability: Built to Withstand: These robust atomizers are designed to function flawlessly within a temperature range of -10 to 45°C and an environment with humidity levels of up to 75%. This adaptability allows for their integration into diverse environments without compromising performance.

Specialization in Small Particle Generation

Piezo Direct specializes in producing atomizers that generate exceptionally small particles, making them ideal for applications like nebulizers. This is because only particles smaller than 5 micrometers can effectively reach the lungs. To maximize nebulizer effectiveness, it’s crucial to produce as many particles as possible within this size range.

Our technology allows for the creation of mesh holes as small as 2.5 microns, the smallest achievable size with current mesh-based atomizer technologies. Since particle size (or Mass Median Aerodynamic Diameter, MMAD) directly correlates with mesh hole size, our atomizers are particularly well-suited for nebulizer applications.

Beyond Nebulization

Piezo atomizers have applications in a multitude of industries, including:

- Medical and Healthcare: Precise and targeted respiratory treatments become a reality with the integration of our atomizers into inhalation therapy devices.

- Agricultural Revolution: Cultivate efficiency and precision in crop spraying systems. Our atomizers ensure the meticulous distribution of pesticides, fertilizers, and growth regulators, empowering agricultural advancements.

- Personal Care and Cosmetics: Indulge in a refreshing experience with facial misters and fragrance diffusers powered by Piezo Direct’s atomizers.

- Printing and Coating Perfection: Attain unparalleled accuracy in ink, coating, or adhesive deposition within textile printing, 3D printing, and other industrial applications.

- Fuel Atomization for a Greener Future: Enhance fuel efficiency and minimize emissions in combustion systems through the incorporation of our innovative atomizers.

Piezo Atomizers – The Future of Precise Liquid Delivery

Piezo Direct’s piezo atomizers represent a transformative leap forward in liquid atomization technology. Their exceptional versatility, coupled with a commitment to meticulous particle size control, makes them an indispensable asset for a wide range of industries. As we continuously strive for innovation, Piezo Direct remains dedicated to pushing the boundaries of what’s possible, paving the way for a future filled with even more groundbreaking applications of piezo atomization technology.

“After our previous piezoelectric supplier stopped producing a bi-morph with our required specifications, I looked around for a new supplier for replacement. Of the companies I contacted, Piezo Direct provided some of the quickest response times, and said they were able to create a bi-morph to my specifications! Waiting for my samples to conduct testing now.” – Google Review

![]()

Piezo Direct: Your Source for High-Performance Piezo Atomizers

Piezo Direct is your trusted partner for designing and manufacturing world-class piezo atomizers. Our expertise in piezoelectric technology allows us to deliver atomization solutions that surpass industry benchmarks in performance, reliability, and customization capabilities.

Uncompromising Quality in Piezo Atomizer Manufacturing

Our commitment to quality begins with meticulously sourcing premium piezoelectric materials. These materials, renowned for their superior piezoelectric properties and long-term durability, form the backbone of our atomizers’ exceptional performance.

Precision Engineering for Unmatched Atomization

We employ state-of-the-art manufacturing processes to transform piezoelectric materials into atomizers of extraordinary precision. Our skilled technicians utilize cutting, dicing, and shaping techniques to achieve the ideal geometries and dimensions required for optimal atomization results.

Rigorous Testing Ensures Reliability

Every piezo atomizer leaving our facility has undergone extensive testing and validation. We assess atomization efficiency, droplet size distribution, flow rates, and overall performance, ensuring our products consistently exceed your expectations.

Customization: Tailored Solutions for Your Application

We understand the unique needs of our clients across diverse industries. Piezo Direct offers bespoke piezo atomizer solutions, including customized designs, adjustable frequencies, and specialized nozzle configurations to address your specific application requirements.

Standard Products Offering

In addition to our custom atomizers, Piezo Direct now offers standard off-the-shelf piezo atomizers for immediate integration into your applications. These standard products provide the same high-quality performance and precision engineering as our custom solutions, making them ideal for projects with quicker timelines or more general requirements. Our standard atomizers are available in a variety of configurations, ensuring you can find the right solution to meet your atomization needs without the need for customization.

Benefits of Our Standard Products:

- Ready-to-ship for faster deployment

- Industry-leading quality and reliability

- Available in mesh-based and disc-based designs

- Ideal for common applications such as humidification, medical nebulizers, and consumer products

Industries We Serve:

- Medical: Inhalers, nebulizers, medical coatings

- Industrial: Humidification, fuel injection, cooling, dust suppression

- Agriculture: Pesticide and nutrient delivery

- Consumer Goods: Humidifiers, aroma diffusers, skincare

- Printing: Inkjet atomization

- And more!

Why Partner with Piezo Direct?

- Precision-focused manufacturing

- Uncompromising quality control

- Customization expertise

- Standard product availability for faster solutions

- Dedication to client success

- Leading innovator in atomization technology

Whether you need a fully customized piezo atomizer or a high-quality standard product, Piezo Direct has the solutions to meet your needs. Explore our standard product offerings or contact us to discuss your custom atomization requirements.

Features

Applications

Specifications

Understanding Piezo Atomizers: Features and Benefits for Optimal Atomization

Piezoelectric atomizers are versatile tools that leverage the power of piezoelectric materials to convert liquids into fine mists or aerosols. Their unique features make them ideal for numerous precision applications. Here’s a breakdown of their advantages:

Key Features of Piezo Atomizers

Highly Efficient Atomization: Piezo atomizers transform liquids into fine droplets with exceptional efficiency. This ensures optimal coverage and distribution of the atomized substances, resulting in effective and consistent results.

Adjustable Droplet Control: Optimize your process by customizing droplet size. Piezo atomizers allow you to fine-tune droplet size through adjustments to voltage, frequency, and flow rate. This adaptability is essential for tailoring atomization to your exact requirements.

Uniform and Precise Spray Patterns: Achieve reliable results with piezo atomizers, which deliver remarkably even and consistent spray patterns. This precision is critical for applications like:

- Industrial Coatings

- Inkjet Printing

- Agricultural Crop Spraying

- Medical nebulizers

Rapid Atomization: When time is of the essence, piezo atomizers excel due to their high-speed liquid-to-aerosol conversion. They’re ideal for:

- Medical inhalation devices

- Fast-paced industrial processes

Energy Efficiency: Piezo atomizers operate with minimal power consumption, reducing your operational costs and increasing sustainability compared to alternative atomization methods.

Versatility with Diverse Liquids: These atomizers effectively handle a wide range of liquids, including:

- Water-based solutions

- Oils

- Solvents

- Suspensions

- Specialized fluids (medical, industrial, etc.)

Compact and Lightweight: Piezo atomizers integrate seamlessly into systems, thanks to their small size and minimal weight. This is a major advantage for devices where space and weight are primary concerns.

Fast Response for Precise Control: Piezo atomizers allow for immediate on/off switching and rapid adjustments, enabling fine control over atomization processes.

Applications Across Industries

Piezo atomizers find use in a multitude of industries, including:

- Medical: Inhalers, nebulizers, humidifiers

- Industrial: Coatings, fuel injection, 3D printing, process control

- Agriculture: Crop spraying, pest control, humidification

- Consumer Goods: Humidifiers, air purifiers, fragrance diffusers

Piezo Direct: Your Source for Advanced Piezo Atomizers

If you’re seeking precision, efficiency, and control in your atomization processes, Piezo Direct offers a wide selection of high-quality piezo atomizers. Our team can guide you to the perfect solution for your unique needs. Contact us today!

Applications of Piezo Atomizers: Versatility Across Industries

Piezo atomizers harness the power of piezoelectric transducers to create fine mists, making them valuable tools in diverse fields. Explore the extensive ways these atomizers are transforming industries:

Humidification and Air Purification

- Industrial humidification: Maintain optimal humidity levels in manufacturing facilities, storage areas, and other industrial settings to ensure product quality and process efficiency.

- Home humidifiers: Create a comfortable living environment by preventing dry air and its associated health issues.

- Air purifiers: Used in conjunction with air purification systems, piezo atomizers can disperse water-soluble cleaning agents or disinfectants for cleaner, healthier air.

Medical Applications

- Inhalers and nebulizers: Deliver precise doses of medication in mist form directly to the lungs for the treatment of asthma, COPD, and other respiratory conditions.

Fragrance and Flavor Industries

- Aroma diffusers: Enhance ambiance and well-being by atomizing essential oils, creating a relaxing and pleasant atmosphere.

- Flavor atomizers: Innovate food and beverage preparation by delicately infusing flavors and aromas.

- Car fragrance: Provide a personalized scent experience within vehicles.

Industrial Applications

- Fuel injectors: Improve combustion efficiency in engines by atomizing fuel into a fine mist for optimal fuel-air mixture.

- Cooling systems: Atomized water provides precise and energy-efficient cooling in industrial settings and greenhouses.

- Dust suppression: Control dust in construction and mining sites by atomizing water to bind airborne particles.

Additional Innovative Applications

- Skin care: Gently distribute skincare products or mists for hydration and refreshment.

- Disinfection: Effectively spread disinfectants for surface and space sanitization.

- Medical device coatings: Applied for evenly-spread, precise coatings on medical devices and implants.

- 3D Printing: Utilized for binder jetting to create intricate 3D objects.

- Agriculture: Facilitate controlled delivery of pesticides or nutrients in agricultural settings.

- Code Symbols Used for applying fine, accurate markings with ink.

Specifications

Stainless Mesh Single Chip Atomizers

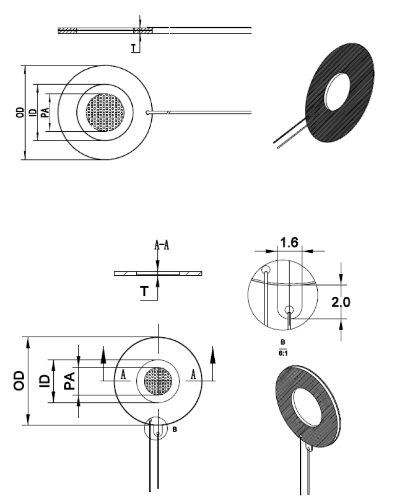

To ensure optimal integration of our single-chip atomizers, we provide a detailed breakdown of their technical specifications:

| Model | Dimensions ODxIDxPAxT*[mm] | Frequency [kHz]±10 | Impedance [ohm] | Capacitance [nF]±30% | Atomization quantity* [mI/min]±30% |

| SST-113-0.6.0D-1(6) | 16×7.8x5x0.75 | 113 | < 100 | 4.5 | 2.50 |

| SST-113-0.6.0D-1(8) | 16×7.8x5x0.75 | 113 | < 100 | 4.5 | 4.50 |

| SST-113-0.6.0D-1(10) | 16×7.8x5x0.75 | 113 | < 100 | 4.5 | 7.00 |

| SST-113-0.6.0D-1(12) | 16×7.8x5x0.75 | 113 | < 100 | 4.5 | 8.50 |

PA*: Perforated area

Atomization quantity*: the experimental liquid is water

Understanding the Implications

These specifications offer valuable insights for engineers and integrators. For instance, the frequency range dictates the type of driving signal required for operation, while understanding impedance and capacitance is crucial for designing suitable circuits. The atomization quantity, in conjunction with the particle size capabilities, provides an indication of the mist volume and fineness generated, which are key factors in applications like nebulizers.