The benefits of piezoelectricity are being increasingly harnessed in medical community due to the precision required by the application. The mechanisms provided by piezo components offer unmatched control, precision, and accuracy. Piezo components, such as piezo actuators, piezoelectric sensors, and piezo transducers, are unaffected by harsh working environments, temperatures, and magnetic fields, and require no lubrication or maintenance. Piezo components can be made to utilize either the piezoelectric effect or the inverse piezoelectric effect – the first converts mechanical energy/inputs into a proportional electrical energy/output, while the latter inverse effect converts electrical energy/inputs into a proportional mechanical energy/output. Piezo actuators utilize the inverse piezoelectric effect and are specifically used to generate action or make physical adjustments in precisely defined responses to electrical inputs. We will explore a few examples of piezoelectric actuators in medical applications below. Piezo components can offer vast improvements in medical applications where time and accuracy are of the essence.

One example of piezoelectric motion based mechanisms can be seen in laser refractive eye surgery. This surgery uses a high-speed laser to cut into the epithelial layer of the eye and make corrections to the cornea with a laser beam. High precision nanopositioning piezo components, such as stack piezo actuators, are used to move the laser beam to precise locations of the eye to make necessary corrections. Piezo stack actuators are used as drives in the nanopositioning and scanning system to steer and control the laser. When the electrical input of the desired laser path is received, the piezo actuator expands or contracts in small adjustments to move the laser to the defined location. Precision and accuracy of the upmost importance when dealing with the human eye, and piezo components are ideal for nanopositioning medical applications.

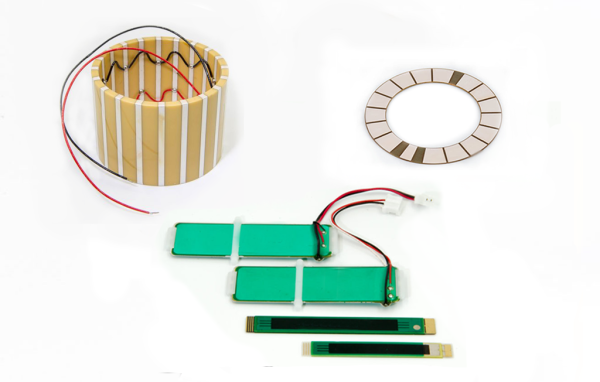

Ventilators and other oxygen supply ventilation devices supply air and oxygen to the patient by inserting a tube into the patient’s nose, mouth, or trachea, and connecting the tube to a ventilator. The ventilator is responsible for pushing a mixture of air and oxygen into the lungs to provide oxygen to the body. Adequate pressure and flow rate are extremely important to properly ventilate the lungs. Piezo components, such as piezoelectric ring actuators and strip piezo bending actuators, are utilized in such devices to control the flow rate and volume displacement. When a voltage is applied, the piezoelectric ring or piezo bending actuator will bend, either opening or closing the valve a precisely defined amount. Piezo bending actuators can achieve a range of motions and forces, making them well suited as valve controls for ventilators. Piezo components also consume very little energy, making piezo bending actuator strips and bending piezoelectric rings extremely reliable in portable ventilation devices.

Nanodosing and precision dosing rely on piezo components to pump/release precise and small volumes of liquid or gas. Lab settings and medicine dosing can implement piezo tubes to dispense droplets in nanoliter or picoliter volumes. When an electrical signal is received by the piezo tube actuator, the piezo tube bends or expands to dispense precisely defined volumes. Lab instruments and dosing equipment can greatly benefit from the precision and accuracy afforded by piezo tubes and piezo cylinders in virtually any environment.

The possible improvements piezo components can provide to medical applications is limitless, and its benefits can already be seen in laser surgery, ventilation systems, nanodosing instruments, and much more. Piezo actuators, such as piezo bending actuators, piezoelectric rings, piezo tubes, piezo cylinders, offer unmatched precision, accuracy, and speed required in all medical applications.

Piezo Direct specializes in custom piezo products, suitable for medical applications. For help with your custom piezo requirement, please contact Piezo Direct at 650-375-7003 or [email protected] to learn more about custom piezo manufacturing.