Piezo Components in Medicinal Equipment

Piezo components, such as piezo actuators, piezoelectric sensors, and piezo transducers, are becoming widely utilized in medical applications due to their unmatched control, precision, and accuracy. Piezo elements are unaffected by harsh working environments, temperatures, and magnetic fields, and require no lubrication or maintenance. Medical engineering has rigid requirements for life-saving equipment, and the diversity and precision offered by piezoceramics is extremely suitable for medical motors, sensors, and any other medical application.

Piezo elements, such as piezo ceramic discs and piezo atomizers, utilize either the piezoelectric effect or the inverse piezoelectric effect. Piezo actuators utilize the inverse piezoelectric effect by converting electrical energy/inputs into a proportional mechanical energy/output. Piezoelectric actuators are specifically used to generate action or make physical adjustments in precisely defined responses to electrical inputs. Piezoelectric sensors utilize the piezoelectric effect by converting mechanical energy/inputs into a proportional electrical energy/output. Piezoelectric ceramic sensors are specifically used to determine the force, pressure, or speed of the mechanical input. Piezoelectric transducers utilize both piezoelectric effects and can produce and receive both electrical and mechanical energy. We will explore a few more examples of piezo actuators, piezo sensors, and piezo transducers in medical applications below.

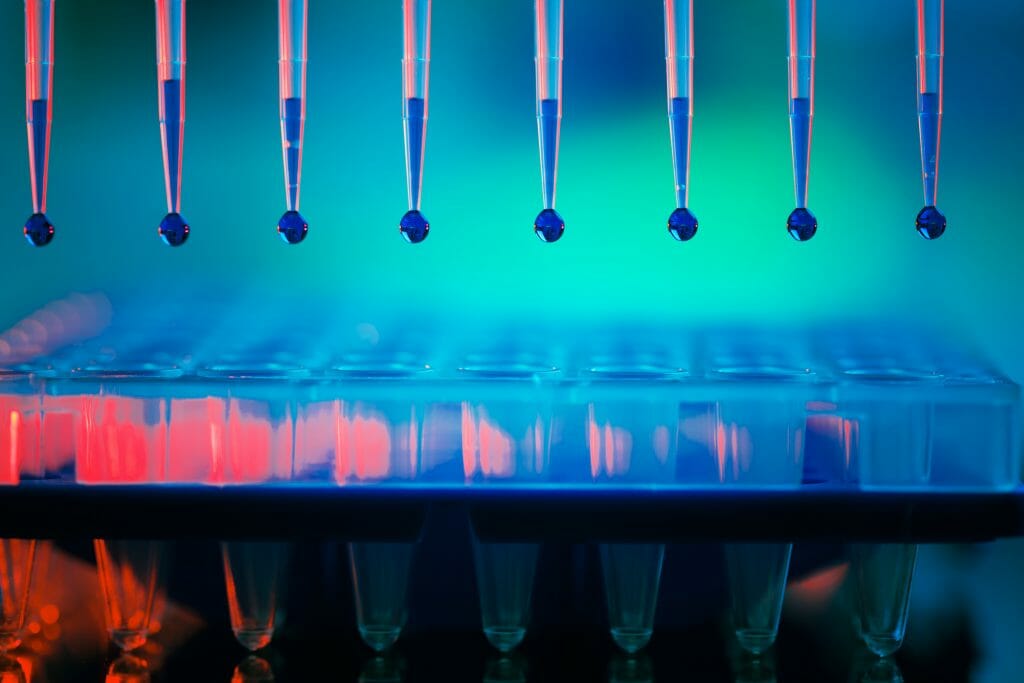

Pipetting and dispensing equipment can implement the mechanical response of piezo actuators to dispense fluid. Multilayer piezo actuators are layers of piezoelectric materials stacked together. Putting many piezoelectric actuators together creates a multiplicative effect on their displacement for the same voltage, amplifying their power. Thus, when a voltage is applied to the multilayer piezo actuator, it expands, creating linear movement and force. When positioned next to a tube of fluid, a multiplayer piezo actuator expands at an electrical signal, pushing into the tube and forcing fluid to be released. The displacement of the piezoelectric actuator can be precisely defined to release the exact amount of fluid needed. Multilayer piezo actuators can achieve fast response, precise linear movement, high force generation, and high load capabilities, making them cost-effective and reliable in dispensers and pipetting systems.

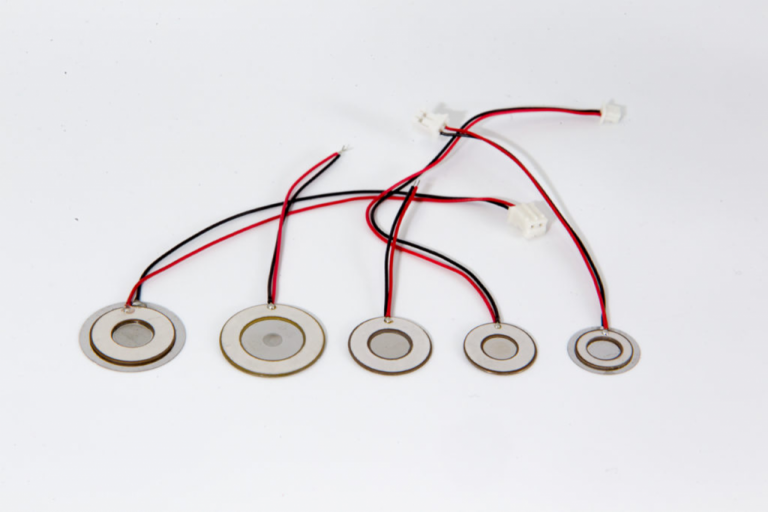

Nebulizers are commonly used to deliver medicine through tiny aerosols to be inhaled. Piezoelectric atomizers or ultrasonic piezoelectric transducers are used to generate vibrations and produce droplets. The droplets are produced by placing a mesh layer on top of the piezo transducer element, usually a piezo disc. When an electrical signal is received by the atomizer, the piezo element will begin to oscillate at ultrasonic frequencies. The rapid oscillation pushes the fluid through the mesh layer, creating tiny droplets safe of inhalation. The droplet size is predefined by the size and number of holes in the mesh layer and there is minimal energy involved. Piezo discs as piezo atomizers are widely used for nebulizers and aerosol generation in medicine.

Blood transfusion and dialysis machines can utilize ultrasonic piezo disc transducers to sense and detect air bubbles or impurities. The piezoelectric discs perform as both a piezo actuator and a piezo sensor to emit and receive ultrasonic pulses. Any changes in reflection pattern or frequency, signaling an air bubble or impurity, are picked up by the piezoelectric disc and the pumping process is halted immediately. Piezoelectric transducers and piezoelectric sensors can also measure and monitor the flow rate. Contactless accuracy and response time in transfusion and dialysis machines are extremely important, making ultrasonic disc piezoelectric transducers an ideal solution for flow rate and bubble detection.

Piezo Direct offers a wide range of piezoelectric products, including fully customizable piezo actuators, piezoelectric sensors, and piezo transducers, available in a variety of shapes. Piezoceramics offer unmatched precision, accuracy, speed, and control necessary in medical applications. For more information about piezoelectric ceramics, please contact Piezo Direct at 650-375-7003 or [email protected] to learn more about custom piezo components.