Basics of the Piezoelectric Effect

Okay, so what’s the deal with piezoelectricity? Basically, it’s a phenomenon where certain materials generate electricity when you squeeze them, or conversely, deform when you apply an electric field. Think of it like a two-way street for energy conversion. It’s all about the material’s crystal structure and how it responds to stress.

- Some materials are naturally piezoelectric, like quartz.

- Others, like certain ceramics, can be made piezoelectric through a process called polarization.

- The amount of electricity generated is proportional to the amount of pressure applied. This is why they are used in precision instruments.

It’s kind of wild to think that something as simple as squeezing a crystal can create electricity. It opens up a lot of possibilities for different applications.

Direct and Inverse Piezoelectric Effects

There are two main types of piezoelectric effects: direct and inverse. The direct piezoelectric effect is when you apply mechanical stress (like pressure or vibration) to the material, and it generates an electrical charge. This is how many sensors work. The inverse piezoelectric effect is the opposite: you apply an electrical field, and the material physically deforms. This is used in actuators and other devices that need precise movements. It’s important to understand both to see how piezoelectric transducers work.

Think of it this way:

- Direct: Mechanical stress → Electrical charge

- Inverse: Electrical charge → Mechanical stress

Key Piezoelectric Materials

Not all materials are created equal when it comes to piezoelectricity. Some materials are much better at it than others. Here are a few key players:

- Quartz: One of the original piezoelectric materials, known for its stability and is used in oscillator circuits.

- Lead Zirconate Titanate (PZT): A ceramic material that exhibits strong piezoelectric effects. It’s commonly used in sensors and actuators.

- Polyvinylidene Fluoride (PVDF): A flexible polymer with piezoelectric properties. It’s used in applications where flexibility is important, like wearable sensors.

Here’s a quick comparison:

| Material | Piezoelectric Coefficient | Pros | Cons |

| Quartz | Low | Stable, well-known | Low output |

| PZT | High | High output, versatile | Contains lead |

| PVDF | Moderate | Flexible, lightweight | Lower output than PZT |

Choosing the right material depends on the specific application and what properties are most important. For example, if you need high sensitivity, PZT might be the way to go. If you need flexibility, PVDF could be a better choice. Understanding the components of piezoelectric transducers is key.

How a Piezoelectric Transducer Works

Principles of Operation

Okay, so how do these piezoelectric transducers actually work? It’s all about the piezoelectric effect, which is a fancy way of saying that some materials generate electricity when you squeeze them, or conversely, deform when you apply an electric field. The core principle is the interconversion of mechanical and electrical energy.

Think of it like this: you apply pressure to a piezoelectric material, and the crystal structure gets a little squished. This squeezing causes positive and negative charges inside the material to separate, creating a voltage. The amount of voltage is proportional to the amount of pressure. Flip it around, and if you apply a voltage, the material changes shape, expanding or contracting depending on the polarity.

Converting Energy Forms

Piezoelectric transducers are really good at converting energy from one form to another. That’s their superpower. They can turn mechanical energy (like pressure, force, or vibration) into electrical energy (voltage), and vice versa. This makes them useful in a ton of different applications. It’s not a perfect conversion, of course; there are always some losses due to things like heat and internal resistance. But overall, they’re pretty efficient.

Here’s a simple breakdown:

- Mechanical to Electrical: Pressure -> Crystal Deformation -> Charge Separation -> Voltage

- Electrical to Mechanical: Voltage -> Crystal Deformation -> Expansion/Contraction -> Mechanical Force

- The piezoelectric effect is key to this conversion.

It’s important to remember that the relationship between force and voltage (or voltage and displacement) is linear within a certain range. Go beyond that range, and the material might not behave predictably, or even get damaged.

Components of a Piezoelectric Transducer

So, what’s inside a typical piezoelectric transducer? It’s usually more than just a chunk of piezoelectric material. Here’s a look at the main parts:

- Piezoelectric Element: This is the heart of the transducer. It’s the actual material (like quartz or a ceramic) that exhibits the piezoelectric effect. The type of material affects the transducer’s sensitivity, operating temperature, and other characteristics.

- Electrodes: These are conductive plates attached to the piezoelectric element. They collect the electrical charge generated by the element when it’s stressed, or they deliver the voltage to the element to make it deform. The electrodes are usually made of a metal like silver or nickel.

- Housing/Packaging: This protects the delicate piezoelectric element and provides a way to mount the transducer. The housing also affects the transducer’s frequency response and environmental resistance. The housing is often made of metal or plastic.

And sometimes, you’ll find other components like:

- Pre-amplifier: To boost the weak signal from the piezoelectric element.

- Signal Conditioning Circuitry: To filter noise and shape the signal.

- Mechanical Interface: To couple the transducer to the system it’s measuring or controlling.

Advantages of Piezoelectric Technology

Precision and Sensitivity

Piezoelectric transducers really shine when it comes to precision. They can detect even the tiniest changes in pressure, force, or acceleration. This makes them perfect for applications where accuracy is key. For example, think about medical devices that need to measure blood pressure with extreme precision, or industrial sensors that monitor the health of machinery by detecting subtle vibrations. The sensitivity of these devices, often in the range of 1-100 mV/g, allows for capturing very fine movements.

Wide Frequency Range Operation

One of the cool things about piezoelectric materials is that they can operate over a broad range of frequencies. We’re talking from a few Hz all the way up to several kHz. This is super useful in dynamic systems. Imagine ultrasound imaging, where high-frequency sound waves are used to create images of internal organs. Or sonar systems that use sound waves to detect objects underwater. Piezoelectric transducers are well-suited for these kinds of applications because they can handle the high frequencies involved.

Durability and Environmental Resistance

Piezoelectric devices are known for their reliability over long periods. Studies have shown that piezoelectric ceramics can withstand over 10^9 cycles of actuation with minimal wear. This makes them ideal for systems that experience high demand, such as automotive knock sensors and industrial actuators. Plus, they can handle harsh conditions. They can function in temperatures ranging from -100°C to 300°C and withstand high pressure. This makes them suitable for aerospace, deep-sea exploration, and high-temperature industrial processes. Their small size and light weight also make them easy to incorporate into low-weight systems. For example, many piezoelectric actuators weigh less than 5 grams but can provide forces greater than 100N. This combination of durability and environmental resistance makes them a solid choice for many applications. The power of piezoelectric technology is clear.

Piezoelectric transducers offer a unique combination of benefits. Their ability to convert mechanical energy into electrical energy, and vice versa, with minimal energy loss, makes them incredibly efficient. This efficiency, coupled with their small size and robustness, positions them as a top choice for various applications, from everyday consumer electronics to advanced industrial and medical equipment.

Diverse Applications of Piezoelectric Transducers

Piezoelectric transducers are incredibly versatile. Their ability to convert mechanical energy into electrical energy, and vice versa, makes them useful in many different fields. Let’s explore some key areas where these transducers are making a real impact.

Medical and Healthcare Innovations

Piezoelectric transducers are essential in modern medicine. One of their most common uses is in diagnostic ultrasonography. Think about those ultrasound images you see during pregnancy – that’s piezoelectricity at work! But it doesn’t stop there. They’re also used in:

- Lithotripsy: Breaking up kidney stones using focused sound waves.

- Surgical tools: Providing precise movements for delicate procedures.

- Drug delivery systems: Controlling the release of medication with high accuracy.

The precision and sensitivity of piezoelectric transducers make them ideal for medical applications where accuracy is critical. They allow for non-invasive diagnostics and targeted treatments, improving patient outcomes.

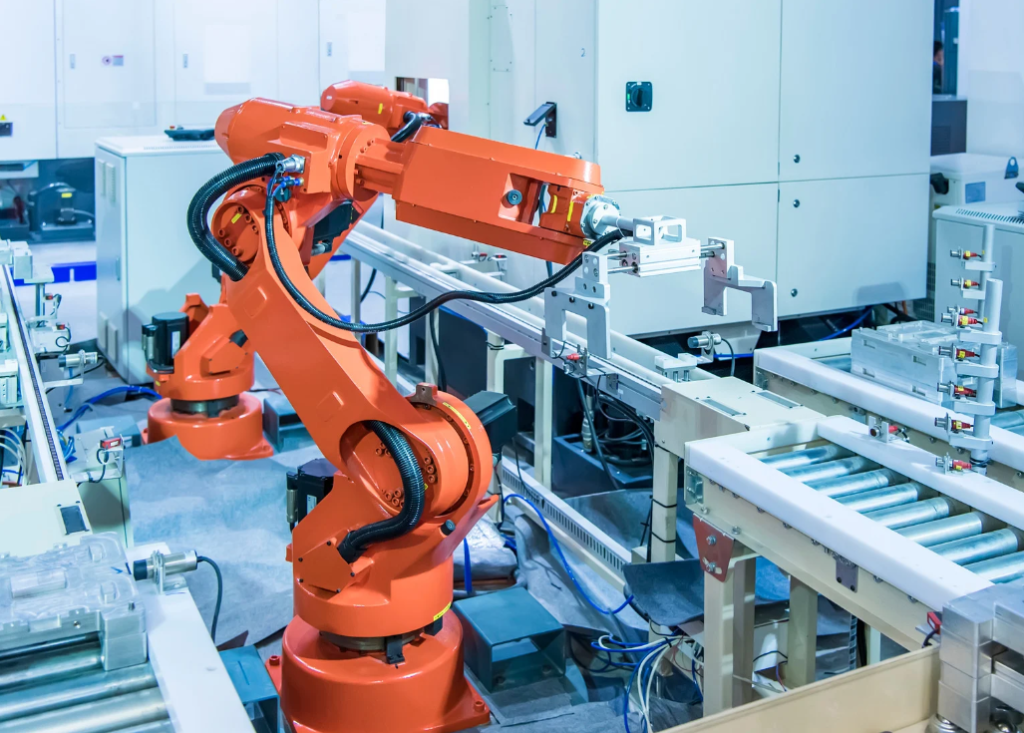

Industrial and Automotive Systems

Outside of healthcare, piezoelectric transducers play a big role in industry and automotive engineering. For example, piezoelectric accelerometers are used to monitor the health of machinery, detecting vibrations that could indicate a problem. Other applications include:

- Fuel injectors: Precisely controlling fuel flow in engines.

- Vibration sensors: Monitoring structural integrity in bridges and buildings.

- Active suspension systems: Improving ride comfort in vehicles.

Energy Harvesting and Sensing

One of the most exciting areas for piezoelectric transducers is energy harvesting. Imagine capturing energy from everyday movements and vibrations to power small devices! This is becoming a reality with:

- Wearable sensors: Powering health monitors and fitness trackers.

- Wireless sensors: Enabling remote monitoring in agriculture and environmental science.

- Self-powered devices: Reducing the need for batteries in various applications.

Piezoelectric materials can operate over a wide frequency range, from a few Hz to several kHz. This improves their application in dynamic systems like ultrasound imaging, sonar and high frequency signal processing.

Integrating Transducers in Data Acquisition Systems

Role of Transducers in Data Collection

Okay, so you’ve got your piezoelectric transducer. Now what? Well, it needs to talk to something, right? That’s where data acquisition systems (DAQ) come in. Think of transducers as the senses of your system, and the DAQ as the brain. The transducer picks up some kind of physical phenomenon – pressure, vibration, whatever – and turns it into an electrical signal. This signal then goes to the DAQ, which is responsible for recording, processing, and displaying that information. Without the right DAQ, you’re basically just shouting into the void.

Signal Conversion and Processing

So, the transducer spits out an electrical signal. Great! But that signal might not be in a format that your DAQ can understand directly. Maybe it’s a really weak signal, or maybe it’s got a bunch of noise mixed in. That’s where signal conditioning comes in. This involves things like:

- Amplification: Making the signal stronger so it’s easier to read.

- Filtering: Removing unwanted noise to clean up the signal.

- Linearization: Correcting for any non-linearities in the transducer’s response.

Think of it like this: you’re trying to listen to someone whispering in a crowded room. Amplification is like turning up the volume, and filtering is like blocking out all the other conversations. Signal processing is a critical step in getting meaningful data from your piezoelectric device.

Ensuring Data Accuracy and Reliability

Alright, you’ve got your signal, it’s clean, and it’s strong. But how do you know it’s actually accurate? This is where calibration and validation come into play. Calibration involves comparing the transducer’s output to a known standard. This helps you identify and correct for any systematic errors. Validation, on the other hand, involves testing the entire system to make sure it’s performing as expected under real-world conditions. Here are some things to keep in mind:

- Regularly calibrate your transducers.

- Use high-quality DAQ equipment.

- Properly shield your cables to minimize noise.

It’s important to remember that garbage in equals garbage out. If your transducer is giving you bad data, no amount of fancy signal processing is going to fix it. Always double-check your setup and make sure everything is working correctly. Data accuracy is key for piezoelectric transducers.

Selecting the Right Piezoelectric Transducer

Okay, so you’re ready to pick out a piezoelectric transducer. It’s not as simple as grabbing the first one you see. There are a few things you really need to think about to make sure you get the right one for your project. Let’s break it down.

Considerations for Application Specifics

First off, what are you actually using this transducer for? Is it going into a medical device, an industrial sensor, or something totally different? The application is going to dictate a lot of the requirements. For example, a high-frequency application will need a transducer designed to operate at those speeds. A low-power application will need a transducer that is efficient. Knowing your application inside and out is the first step.

Here’s a quick checklist to get you started:

- What kind of signal are you trying to detect or generate (pressure, force, vibration, etc.)?

- What’s the expected range of that signal (minimum and maximum values)?

- What’s the required accuracy and resolution?

- What’s the operating environment (temperature, humidity, etc.)?

Material Properties and Performance

Different materials have different piezoelectric properties. Some are more sensitive, some can handle higher temperatures, and some are better suited for specific frequencies. Lead Zirconate Titanate (PZT) is a common choice, but there are other options like quartz and certain polymers. Each has its pros and cons. You can find a PZT supplier that meets your needs.

Here’s a table comparing some common materials:

| Material | Sensitivity | Temperature Range | Frequency Range | Pros | Cons |

| PZT | High | -50°C to 150°C | Low to Medium | High sensitivity, readily available | Contains lead, lower Curie temperature |

| Quartz | Medium | -200°C to 300°C | High | Stable, high Curie temperature | Lower sensitivity, more expensive |

| Polymers | Low | -40°C to 80°C | Low | Flexible, lightweight | Low sensitivity, limited temperature range |

Environmental Factors and Durability

Where is this transducer going to live? Is it going to be exposed to extreme temperatures, humidity, or corrosive chemicals? If so, you need a transducer that can handle it. Look for materials and designs that are resistant to the specific environmental conditions. Also, think about how long you need the transducer to last. A cheap transducer might work fine for a short-term project, but if you need something that’s going to last for years, you’ll need to invest in a more durable option.

It’s easy to overlook environmental factors, but they can have a huge impact on the performance and lifespan of your transducer. Make sure to consider all the potential hazards and choose a transducer that’s up to the challenge. Don’t forget about things like vibration, shock, and electromagnetic interference (EMI), which can also affect performance.

Picking the right piezoelectric transducer can seem tricky, but it’s super important for your project to work well. These little devices turn electricity into motion and vice-versa, and there are many kinds, each good for different jobs. To learn more about how to pick the best one for what you need, check out our website!

Conclusion

So, we’ve gone over a lot about piezoelectric transducers. They’re pretty cool, right? These things can change mechanical energy into electrical energy, and vice versa. That ability makes them useful in a bunch of different areas. Think about medical tools, industrial sensors, and even some newer energy-saving ideas. They are small, tough, and work well in many conditions. This means they will keep showing up in new products and systems. It’s clear these transducers are a big deal for how technology keeps moving forward.

Frequently Asked Questions

What exactly is a piezoelectric transducer?

A piezoelectric transducer is a cool device that uses special materials to change one kind of energy into another. Think of it like this: if you push on it, it makes a tiny bit of electricity. Or, if you send electricity into it, it wiggles or vibrates. It’s super useful for things like making sounds, sensing pressure, or even creating images inside the body.

How does the ‘piezoelectric effect’ play a role?

The ‘piezoelectric effect’ is the main trick. It’s a fancy way of saying certain materials, like some crystals or ceramics, can make electricity when you squeeze or stretch them. And the opposite is true too: if you put electricity on them, they change shape. This back-and-forth magic is what makes these transducers work.

What are the big benefits of using piezoelectric transducers?

These transducers are really good at what they do! They can be super precise, meaning they can measure tiny changes. They also work over a huge range of speeds, from very slow movements to super-fast vibrations. Plus, they’re tough and can handle rough conditions, which makes them last a long time.

Where can I find piezoelectric transducers being used?

You’d be surprised how many places! They’re in medical tools for looking inside your body (like ultrasound), in cars to sense things, and even in systems that try to grab small amounts of energy from vibrations to power little devices. They’re everywhere once you start looking!

How do I choose the best piezoelectric transducer for my project?

When you’re picking one, you need to think about what you want it to do. Are you measuring pressure, sound, or something else? What kind of material is it made from? And will it be in a hot, cold, or wet place? All these things matter to make sure you get the right one for the job.

Can piezoelectric transducers help create energy?

Yes, they can! Since they can turn movement into electricity, some clever folks use them to ‘harvest’ energy from things like vibrations or even footsteps. This collected energy can then power small electronic gadgets, especially in places where it’s hard to plug something in.