What are Piezoelectric Transducers?

Transducers are devices that convert one form of energy into another and can be categorized into many different kinds. Sensors and actuators are both kinds of transducers, with categorization being determined by the direction of the information passed through them. Piezo transducer applications vary greatly. Microphones and guitar pickups convert sounds or vibrations into electrical energy; keyboards sometimes use piezoelectric transducers to detect keystrokes; the list goes on. The most canonical application of piezo transducers was in World War I, where quartz was used to construct a sonar for submarine detection.

Why would you use a Piezoelectric Transducer?

Piezoelectric transducers are extremely versatile and flexible, perfect for a wide range of applications. Whereas traditional transducers face issues with operational conditions and shapes (one likely can’t easily make a banana-shaped traditional transducer, for instance), piezoelectric transducers face none of these restrictions. Furthermore, they are extremely responsive to change, both in terms of speed and range.

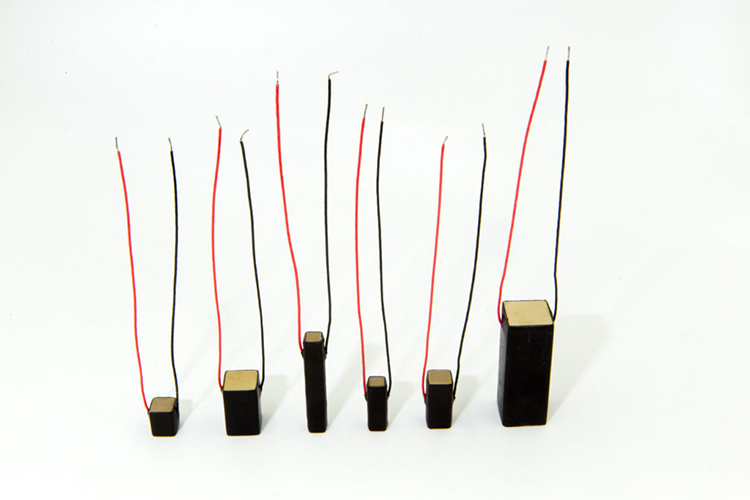

Piezo transducers can be manufactured in a variety of shapes and sizes, including piezo disc, piezoelectric tube, piezo ring, and other custom piezo elements.

Why is Piezo Direct the Best Choice?

As mentioned above, piezo transducers can take on a large variety of shapes and sizes. On top of that, operational input and output ranges may also need to be tuned for a design to work, and other solutions such as transformers and amplifiers can easily introduce error and design complications. Piezo Direct’s high degree of customizability and competitive pricing makes Piezo Direct the best piezoceramic manufacturer partner you can find! Please call us today for more information, in California, at 650-375-7003 or email us at [email protected].