What are Piezoelectric Ultrasonic Atomizing Transducers?

Ultrasonic transducers are often used to atomize liquid and fluid solutions by harnessing the power of ultrasonic vibrations. These ultrasonic piezo elements, also called atomizing transducers or piezo atomizers, work by creating a vibration mechanical response to an electrical input. When an electrical charge or input (AC voltage) is applied to the atomizing transducer, the piezo element generates ultrasonic vibrations. Piezo Direct offers atomizing transducers that can be customized to produce a wide range of flow rates and droplet sizes. Our engineers are able to assist in defining ultrasonic atomizers transducer specifications depending on your desired results. The uses for atomizing transducers are increasing everyday, and Piezo Direct is excited to be a partner in providing the best custom ultrasonic transducers for all applications.

What are Atomizing Transducers?

Atomizing transducers atomize liquids by using ultrasonic vibrations to push the liquid solution through a mesh layer, creating micron-size droplets. Let’s take a closer look at the component parts of piezo atomizing transducers. A fluid solution is placed in a reservoir, surrounded by a piezo element, usually a piezo disc. A perforated mesh layer with many tiny holes is placed on top of the liquid reservoir and piezo element. When an electrical voltage is applied to an atomizing transducer, the piezo transducer generates ultrasonic frequencies. The rapid ultrasonic vibration from the atomizing transducer causes the fluid to be pushed through the mesh layer, producing tiny droplets or mist. The micron-size droplets produced by the atomizing transducer, or ultrasonic nebulizer, are extremely uniform in size and distribution because the mesh layer is engineered with a precise number of holes that are all a specific size. The number of holes and size of holes in the mesh disc is a key factor in determining the droplet size and flow rate.

- Detailed Mechanics

- Advantages and Disadvantages

- Applications

- Shapes

Detailed Mechanics

Understanding the Intricacies of Ultrasonic Piezo Atomizing Transducers

At Piezo Direct, we pride ourselves on our advanced expertise in the realm of piezoelectric technology, especially in the context of ultrasonic piezo atomizing transducers. In this section, we will explore the intricate mechanics that underpin these sophisticated devices.

Piezo atomizing transducers represent a pinnacle of precision engineering in the field of liquid atomization. They utilize high-frequency vibrations, typically within the range of 100-500 kHz, which is considerably higher than that of conventional ultrasonic nebulizers. This advanced technology allows for a more efficient and controlled atomization process.

The core components of these transducers include:

- Piezoelectric Element: This is the heart of the transducer, responsible for converting electrical energy into mechanical vibrations.

- Diaphragm: Attached to the piezoelectric element, the diaphragm translates vibrations into dynamic motion.

- Liquid Reservoir: This component holds the liquid before it is atomized.

Upon application of an electric current, the piezoelectric element vibrates at high frequencies. These vibrations are transferred to the diaphragm, which oscillates to create pressure waves in the liquid. This process culminates in the atomization of the liquid into a fine, uniform mist.

Factors influencing the droplet size include:

- Frequency and amplitude of vibrations.

- Liquid viscosity.

- Nozzle design, encompassing size and shape.

Typically, the droplets range from 5-20 microns in size, ideal for applications needing larger aerosol particles.

Modules vs. Assemblies: Clarifying the Terminology

In the realm of transducer technology, the distinction between ‘modules’ and ‘assemblies’ is crucial:

Modules:

- A module is essentially a component of a larger system, providing specific functionality.

- In piezoelectric transducers, a module could encompass piezoelectric elements, associated wiring, connectors, and housing. These are integral to the transducer’s operation but do not form a complete device in themselves.

- Modules are designed for integration into broader systems or products, requiring additional elements or integration for full functionality.

Assemblies:

- Assemblies, on the other hand, are fully assembled and operational units, ready for immediate application in specific settings.

- A fully assembled transducer would include all necessary components, configured to work autonomously in its designated role.

- These are more aligned with “plug-and-play” solutions, catering to clients who seek ready-to-use, comprehensive solutions.

At Piezo Direct, our expertise lies in crafting transducer modules that embody the essential functional elements but are not complete devices in themselves. Our modules offer the foundational aspects of a transducer, necessitating further integration by the customer into a larger system for a specific application.

Our foray into the detailed mechanics of ultrasonic piezo atomizing transducers underscores our commitment to precision, efficiency, and innovation. By distinguishing between modules and assemblies, we aim to provide clarity and cater to the diverse needs of our clientele. Whether integrating a module into an existing system or seeking a comprehensive solution, Piezo Direct stands at the forefront of piezoelectric innovation, ready to meet and exceed the expectations of the most demanding applications.

Advantages and Disadvantages

In this content, we’ll explore the advantages and disadvantages of ultrasonic piezo atomizing transducers.

Advantages of Piezo Atomizing Transducers

- Versatility: Piezo atomizing transducers can be used to generate both fine and large droplets, making them suitable for a wide range of applications, such as humidification, spraying, and coating.

- Low clogging: Piezo atomizing transducers are less prone to clogging compared to ultrasonic nebulizers, making them more reliable and efficient.

- High durability: Piezo atomizing transducers have a longer lifespan compared to ultrasonic nebulizers, making them a more cost-effective solution in the long run.

Disadvantages of Piezo Atomizing Transducers

- Higher energy consumption: Piezo atomizing transducers require higher energy consumption compared to ultrasonic nebulizers, making them less energy-efficient.

- Louder noise generation: Piezo atomizing transducers generate more noise compared to ultrasonic nebulizers, making them unsuitable for use in environments where noise levels need to be kept to a minimum.

- Larger droplet size: Piezo atomizing transducers generate larger droplets compared to ultrasonic nebulizers, making them unsuitable for applications that require fine aerosols.

In summary, piezo atomizer transducers have their advantages and disadvantages. Piezo atomizing transducers are versatile, reliable, and have a longer lifespan, but require higher energy consumption, generate more noise, and generate larger droplets. The choice of technology should be based on the specific requirements of the application.

Applications

Ultrasonic piezo atomizing transducers have a wide range of applications in various industries. In this content, we’ll explore some of the common applications of piezo atomizing transducers.

Applications of Piezo Atomizing Transducers

Atomizing transducers can also produce larger droplets that can be seen in aroma diffusers and humidifiers. Ultrasonic oscillation disrupts the surface of the fluid with mechanical vibrations that forces the fluid to break apart into small droplets, expelled through the mesh layer on the piezo atomizing transducer. These atomizing ultrasonic nebulizers are ideal for commercial diffusers, humidifiers, and sprayers that require various levels of output depending on application. Consistent predefined droplet sizes, long life, no audible noise, and the lightweight and compact nature of piezo atomizing transducers make them ideal ultrasonic nebulizers for air humidifiers, aroma diffusers, paint sprayers, and much more.

- Agricultural Applications: Piezo atomizing transducers are used in agricultural applications for crop spraying. They are used to generate a fine mist of pesticides or fertilizers that can be applied to crops evenly and efficiently.

- Industrial Applications: Piezo atomizing transducers are used in industrial applications for spray coating and surface cleaning. They are used to generate a fine mist of coating or cleaning solution that can be applied to a surface evenly.

- Personal Care Applications: Piezo atomizing transducers are used in personal care applications, such as perfume atomizers and skin care devices. They are used to generate a fine mist of fragrance or skincare products that can be applied to the skin evenly.

- Laboratory Applications: Piezo atomizing transducers are used in laboratory applications for sample preparation and analysis. They are used to generate a fine mist of solutions that can be used for chromatography and mass spectrometry analysis.

In summary, piezo atomizing transducers have a wide range of applications in various industries. Piezo atomizing transducers are commonly used in agricultural, industrial, personal care, and laboratory applications. The versatility of these technologies makes them ideal for a wide range of applications where fine mist or aerosol generation is required.

Shapes

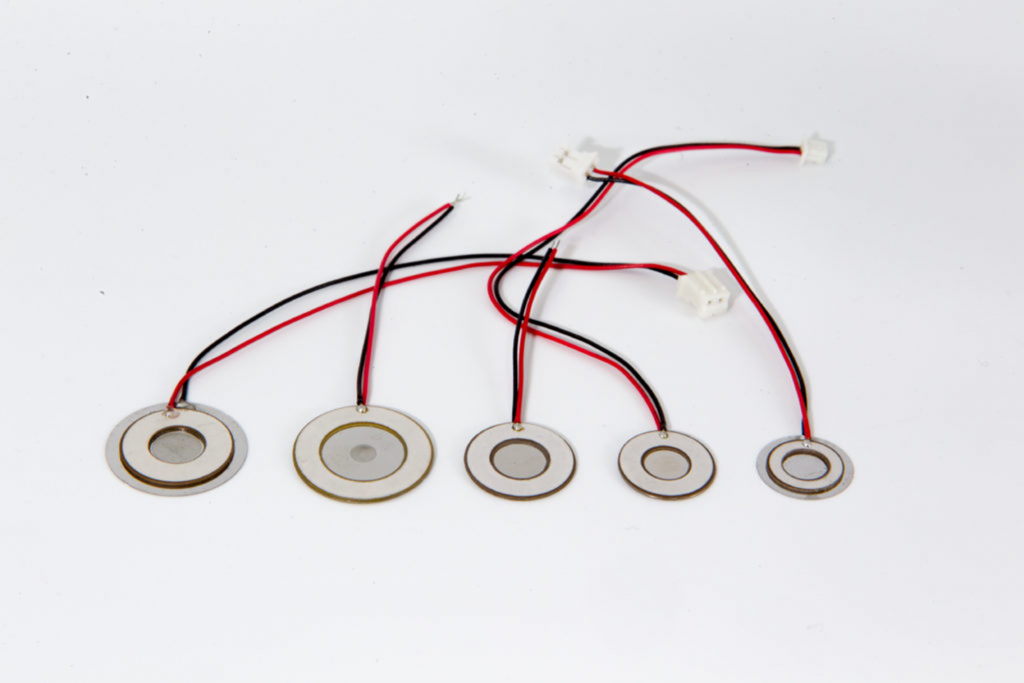

Piezo atomizing transducers come in a variety of shapes and sizes to suit different applications. In this content, we’ll explore the common shapes of piezo atomizing transducers.

Shapes of Piezo Atomizing Transducers

- Flat Disc: Flat disc piezo atomizing transducers are the most common shape and are used in a variety of applications, such as crop spraying, surface coating, and personal care applications. They are typically made from ceramic or metal and can generate a fine mist or spray.

- Cone-Shaped: Cone-shaped piezo atomizing transducers are often used in laboratory applications, such as sample preparation and analysis. They are designed to direct the mist or spray onto a specific area or sample.

- Tubular: Tubular piezo atomizing transducers are used in industrial applications, such as spray drying and surface cleaning. They are designed to generate a large volume of mist or spray and can cover a large area.

- Custom Shapes: Piezo atomizing transducers can also be made in custom shapes to suit specific applications. For example, a piezo atomizing transducer can be designed to fit the shape of a product, such as a perfume bottle, to create a fine mist of fragrance.

In summary, piezo atomizing transducers come in a variety of shapes and sizes to suit different applications. Piezo atomizing transducers can be flat disc, cone-shaped, tubular, or custom-shaped. The shape of the transducer will depend on the specific application and the desired mist or spray output.

At Piezo Direct, we manufacture ultrasonic atomizing transducers using high-quality piezoelectric ceramics engineered for precision and reliability. These components use high-frequency mechanical vibrations to convert liquids into fine mist without the need for heat, making them ideal for humidifiers, medical nebulizers, fragrance diffusers, and fuel atomization systems. Our ultrasonic atomizers are custom-built to meet exact application requirements—offering fine droplet size control, energy efficiency, and long operational lifespans. Whether you need standard or fully customized atomizing transducers, Piezo Direct delivers with fast turnaround and expert engineering support.

Atomizing transducers can be customized to a certain number of holes of the same size to produce the exact output required. Contact us for more information!