Basic Principles of Ultrasonic Atomization

An ultrasonic atomizer uses a thin plate with tiny holes, known as a mesh, connected to a vibrating PZT (piezoelectric transducer). When the device is on, the mesh moves in small, regular patterns. This movement releases energy into the liquid, causing it to break apart into tiny droplets. This process is key to how ultrasonic atomizers work.

Components of an Ultrasonic Atomizer

The main parts of an ultrasonic atomizer include:

- Mesh Plate: A thin plate with micro-apertures.

- Piezoelectric Transducer (PZT): Vibrates the mesh to create droplets.

- External Medium: The atmosphere where the droplets are released.

- Internal Chamber: Holds the liquid to be atomized.

Applications of Ultrasonic Atomizers

Ultrasonic atomizers are used in many fields. They can be found in:

- Aroma Diffusers: To spread pleasant scents.

- Humidifiers: To add moisture to the air.

- Sprayers: For various commercial uses.

Understanding the basics of ultrasonic atomizers helps in grasping more complex topics like vibrational analysis and performance optimization.

Piezoelectric Effect in Ultrasonic Atomizers

Understanding the Piezoelectric Effect

The piezoelectric effect is the ability of certain materials to generate an electric charge in response to mechanical stress. This principle is key to how ultrasonic atomizers work. When an electrical charge is applied to a piezoelectric material, it vibrates at a high frequency. These vibrations are then used to break up liquids into tiny particles.

Role of Piezoelectric Materials

Piezoelectric materials are crucial in ultrasonic atomizers. They convert electrical energy into mechanical energy. This conversion happens at a high-frequency resonance, causing the liquid to break up into fine particles. Piezoelectric ceramics are often used because they are efficient and reliable.

Advantages of Using Piezoelectric Elements

Using piezoelectric elements in ultrasonic atomizers has several benefits:

- High efficiency in converting electrical energy to mechanical energy.

- Ability to produce very fine particles.

- Reliable and long-lasting performance.

The piezoelectric effect is essential for the operation of ultrasonic atomizers, making them highly effective in various applications.

Mechanical Vibrational Analysis

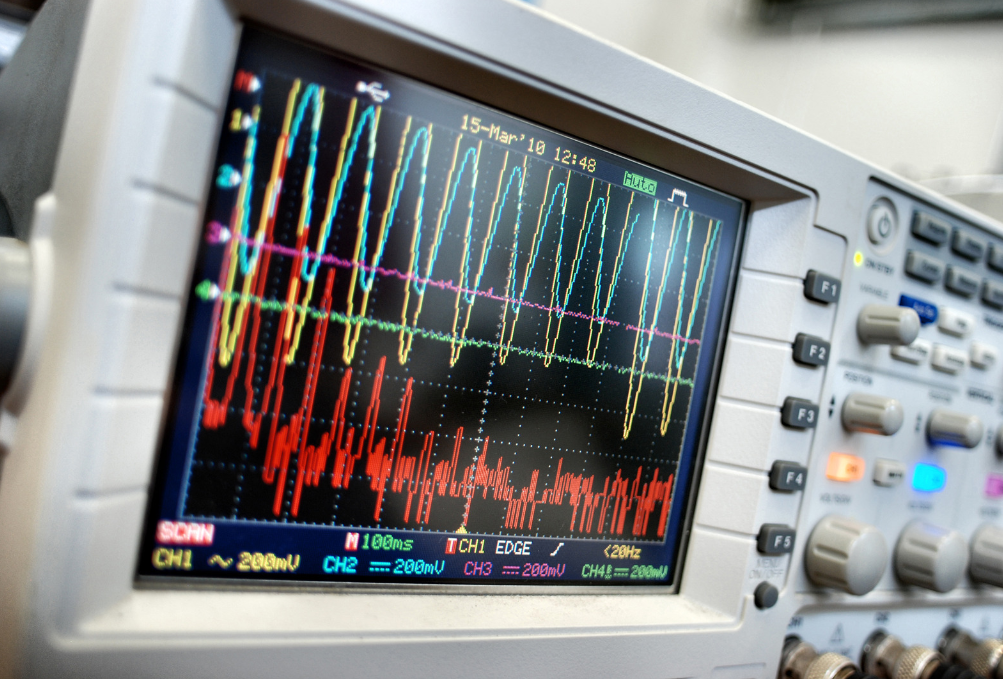

Types of Vibrations in Ultrasonic Atomizers

Ultrasonic atomizers experience two main types of vibrations: free and forced. Free vibrations occur naturally without any external force, while forced vibrations happen when an external force, like an applied voltage, is present. Understanding these vibrations is crucial for optimizing the atomization process.

Impact of Vibrations on Atomization

The vibrations in an ultrasonic atomizer directly affect the atomization mass transfer rate. When the piezoelectric ring vibrates, it causes the metallic thin plate to oscillate, leading to the atomization of the liquid. The efficiency of this process depends on the vibration modes and frequencies.

The finite element analysis provided a clear insight into the process of ultrasonic atomization.

Methods to Control Vibrational Behavior

Controlling the vibrational behavior of an ultrasonic atomizer is essential for achieving optimal performance. Some methods include:

- Adjusting the applied voltage to the piezoelectric ring

- Modifying the design of the metallic thin plate

- Using different materials for the components

These methods help in fine-tuning the device to achieve the desired atomization efficiency.

Design and Construction of Ultrasonic Atomizers

Material Selection for Components

Choosing the right materials is crucial for building an efficient ultrasonic atomizer. Materials must withstand high-frequency vibrations and resist corrosion from liquids. Common materials include stainless steel for durability and ceramics for their piezoelectric properties.

Design Considerations for Efficiency

Efficiency in ultrasonic atomizers depends on several factors. The design must ensure optimal energy transfer from the piezoelectric element to the liquid. This involves precise alignment of components and minimizing energy loss. Additionally, the micro-apertures in the mesh should be uniformly distributed to ensure consistent droplet size.

Challenges in Ultrasonic Atomizer Design

Designing ultrasonic atomizers comes with its own set of challenges. One major issue is controlling the vibrational behavior to achieve consistent atomization. Another challenge is ensuring the device can handle different types of liquids without compromising performance. Engineers must also consider the ease of maintenance and cost-effectiveness of the design.

Performance Optimization

Factors Affecting Atomization Efficiency

Several factors can influence the efficiency of an ultrasonic atomizer. These include the frequency of the ultrasonic waves, the properties of the liquid being atomized, and the design of the atomizer itself. Ultrasonic atomizing transducers play a crucial role in determining how well the device performs. The intricate design utilizes the sides of the mesh to achieve exceptional liquid atomization, ensuring optimal performance.

Techniques for Enhancing Performance

To enhance the performance of an ultrasonic atomizer, consider the following techniques:

- Adjusting Frequency: Fine-tuning the frequency can help achieve better atomization.

- Optimizing Liquid Properties: Using liquids with suitable viscosity and surface tension can improve efficiency.

- Design Improvements: Modifying the design of the atomizer can lead to better performance.

Common Issues and Troubleshooting

Common issues with ultrasonic atomizers include clogging, inconsistent spray patterns, and reduced efficiency. Troubleshooting these problems often involves cleaning the atomizer, checking for blockages, and ensuring that the liquid properties are within the optimal range.

Regular maintenance and proper usage can significantly extend the lifespan and efficiency of an ultrasonic atomizer.

Applications in Various Industries

Medical and Healthcare Applications

Ultrasonic atomizers are widely used in the medical field. They help in nebulizing medications for patients with respiratory issues. These devices ensure that the medicine is broken down into tiny droplets, making it easier for patients to inhale. Additionally, they are used in dental equipment for cleaning and in surgical tools for precise cutting.

Industrial Uses of Ultrasonic Atomizers

In the industrial sector, ultrasonic atomizers play a crucial role. They are used in processes like coating, where a fine mist of material is needed. This technology is also employed in additive manufacturing to create detailed and precise parts. Moreover, ultrasonic atomizers are essential in textile machines for applying treatments to fabrics.

Environmental and Agricultural Applications

Ultrasonic atomizers have significant applications in environmental and agricultural fields. They are used to create fine mists for humidifying greenhouses, ensuring optimal plant growth. In environmental science, these devices help in dispersing chemicals for air and water treatment. They are also used in experiments to understand the mechanism by which the ultrasonic vibration at the gas-liquid interface causes the atomization of liquid.

Ultrasonic atomizers are versatile tools that find applications across various industries, from healthcare to agriculture, making processes more efficient and effective.

Summary:

In summary, ultrasonic atomizer transducers are fascinating devices that use high-frequency vibrations to turn liquids into tiny droplets. By understanding the basic parts and how they work together, we can see how important these devices are in many fields, from medical treatments to industrial processes. The piezoelectric elements and the thin mesh plate play key roles in making the atomization process efficient and controlled. As technology advances, we can expect even more innovative uses for these transducers, making our lives easier and more efficient.

Frequently Asked Questions

What is an ultrasonic atomizer?

An ultrasonic atomizer is a device that uses high-frequency sound waves to turn liquids into tiny droplets. It has a thin plate with small holes and a vibrating part called a piezoelectric element.

How does an ultrasonic atomizer work?

An ultrasonic atomizer works by vibrating a thin plate with tiny holes using a piezoelectric element. When the plate vibrates, it creates small droplets from the liquid in contact with it.

What is the piezoelectric effect?

The piezoelectric effect is when certain materials produce an electric charge in response to mechanical stress. In ultrasonic atomizers, this effect is used to create vibrations that help turn liquids into droplets.

What are the main parts of an ultrasonic atomizer?

The main parts of an ultrasonic atomizer include a piezoelectric element, a thin plate with tiny holes, and a liquid reservoir. The piezoelectric element vibrates the plate, which then creates droplets from the liquid.

What are some common uses of ultrasonic atomizers?

Ultrasonic atomizers are used in many fields, including medical treatments, industrial processes, and agriculture. They help in tasks like humidifying air, spraying coatings, and delivering medication.

How can I improve the performance of my ultrasonic atomizer?

To improve the performance of an ultrasonic atomizer, make sure it is clean and properly maintained. Also, using the right liquid and adjusting the vibration settings can help enhance its efficiency.