The Piezoelectric Effect Explained

Okay, so what’s the deal with these PZT discs? It all starts with something called the piezoelectric effect. Basically, it’s like this: you squish or stretch certain materials, and they generate electricity. Or, flip it around, apply electricity, and they change shape. PZT, which stands for Lead Zirconate Titanate, is a superstar material when it comes to this effect. It’s way more pronounced than in other materials, which is why it’s used in so many things.

Think of it like this:

- Mechanical Stress –> Electrical Charge (Direct Piezoelectric Effect)

- Electrical Field –> Mechanical Strain (Inverse Piezoelectric Effect)

It’s all about the crystal structure inside the material. When it’s stressed, the positive and negative charges inside shift a bit, creating a voltage. Pretty neat, huh?

Key Material Characteristics of PZT

PZT isn’t just one thing; it’s a whole family of materials. The exact recipe – the amounts of lead, zirconium, and titanium – changes its properties. Some PZTs are better at generating voltage, while others are better at changing shape. Here’s a quick rundown of some important characteristics:

- Piezoelectric Coefficients: These tell you how much voltage you get for a certain amount of pressure, or how much it strains for a given electric field. Higher is usually better.

- Curie Temperature: This is the temperature where PZT loses its piezoelectric properties. You definitely don’t want to go above this!

- Dielectric Constant: This affects how much energy the PZT can store. It’s important for applications where you’re switching the voltage quickly.

- Density: Affects the weight of the component and its acoustic impedance, important for ultrasound applications.

| Property | Typical Value | Importance |

| Piezoelectric d33 | 200-600 pC/N | Sensitivity in sensors, force in actuators |

| Curie Temperature | 200-350 °C | Max operating temperature |

| Dielectric Constant | 500-4000 | Energy storage, impedance matching |

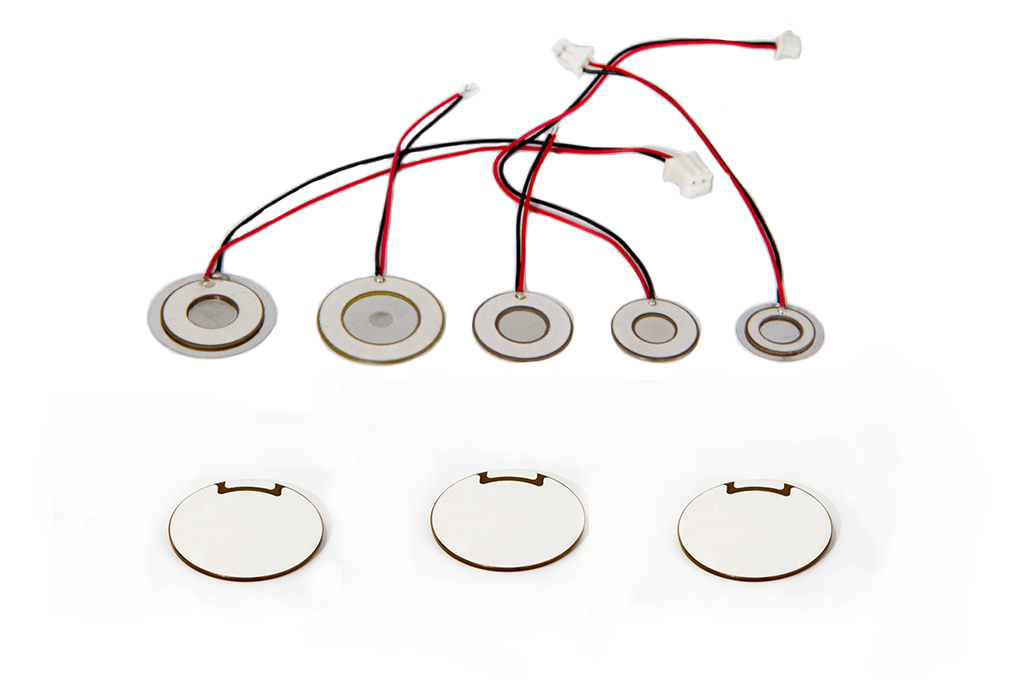

Manufacturing and Polarization of PZT Discs

Making PZT discs is a multi-step process. First, you mix the powders, then you heat them up to form a solid ceramic. But here’s the thing: when it comes out of the oven, it’s not piezoelectric yet! You have to polarize it. This involves applying a strong electric field at a high temperature. This lines up all the tiny crystal domains inside the material, kind of like aligning magnets. Once it’s cooled down with the field still on, it stays polarized, and now you’ve got a piezoelectric material ready to go.

The polarization process is super important. It’s what gives the PZT its directionality. You can think of it like charging a battery – you’re storing energy in the material by aligning those domains. If you heat it up too much or apply a strong electric field in the wrong direction, you can de-polarize it, and it’ll lose its piezoelectric properties. So, handle with care!

PZT Discs in Advanced Sensing Technologies

PZT discs are really useful in sensing tech because they can turn mechanical energy (like pressure or vibration) into electrical signals, and vice versa. This ability makes them perfect for all sorts of sensors that need to be both sensitive and accurate. Think about it – tiny changes in pressure can be detected and turned into a signal we can read. It’s pretty cool.

Precision Acoustic Sensing with PZT

PZT discs are often used in microphones and underwater acoustic sensors (hydrophones) because they’re good at picking up sound waves. The disc vibrates when sound hits it, and that vibration creates an electrical signal. The cool thing is that you can tweak the size and shape of the disc to make it more sensitive to certain frequencies. This is super important in applications like sonar, where you need to detect specific sounds from far away. Plus, PZT sensors can be made small, which is great for devices that need to be compact. For example, medical ultrasound transducers use arrays of tiny PZT elements to create detailed images of the inside of the body. These piezoelectric sensors are essential for high-resolution imaging.

Pressure and Force Measurement Applications

Need to measure pressure or force? PZT discs can do that too! When pressure is applied to a PZT disc, it generates a charge proportional to the force. This is used in things like:

- Weighing scales: High-precision scales use PZT sensors to measure weight accurately.

- Automotive sensors: Tire pressure monitoring systems (TPMS) use PZT sensors to keep track of tire pressure in real-time.

- Industrial applications: Monitoring pressure in pipelines or hydraulic systems.

The sensitivity of PZT sensors to pressure changes makes them ideal for applications where even small variations need to be detected. This is particularly important in fields like aerospace, where precise measurements are critical for safety and performance.

Vibration Detection and Analysis

PZT discs are also great for detecting and analyzing vibrations. Because they respond quickly to mechanical stress, they can pick up even subtle vibrations. This is useful in:

- Structural health monitoring: Attaching PZT sensors to bridges or buildings to detect early signs of damage.

- Machine condition monitoring: Monitoring vibrations in machinery to predict when maintenance is needed.

- Seismic sensors: Detecting and measuring ground vibrations caused by earthquakes.

Here’s a simple table showing how PZT sensors are used in vibration analysis:

| Application | Vibration Type | PZT Sensor Output | Analysis Goal |

| Machine Condition Monitoring | High-frequency | Voltage signal | Detect bearing faults, imbalance, misalignment |

| Structural Health Monitoring | Low-frequency | Voltage signal | Detect cracks, corrosion, structural weakness |

| Seismic Monitoring | Very low frequency | Voltage signal | Measure earthquake magnitude and location |

Using PZT technology in these applications allows for early detection of potential problems, saving time and money in the long run.

Actuation Capabilities of the PZT Disc

PZT discs aren’t just for sensing; they’re also pretty good at doing stuff. Their ability to convert electrical energy into mechanical motion makes them useful in a bunch of applications where you need precise and controlled movement. It’s all thanks to the inverse piezoelectric effect, where applying voltage causes the material to deform. Let’s look at some examples.

Generating Precise Mechanical Motion

At its core, a PZT disc can generate very small but precise movements. When you apply a voltage, the disc expands or contracts. The amount of movement is proportional to the applied voltage. This makes them ideal for applications where accuracy is key. Think about positioning something with extreme precision – that’s where PZT actuators shine. The amount of displacement can be controlled with high resolution, often down to the nanometer scale. This level of control is hard to achieve with traditional mechanical systems.

Micro-Positioning Systems

Micro-positioning systems are a prime example of PZT actuation in action. These systems are used in a variety of fields, from semiconductor manufacturing to scientific instrumentation. Imagine needing to move a tiny sample under a microscope with incredible accuracy. PZT actuators can do that. They’re often used in stages that move in X, Y, and Z directions, allowing for three-dimensional positioning. The fast response time of PZT materials also means these systems can operate at high speeds. Piezo actuators are really useful in these situations.

Fluid Control and Atomization

Another interesting application is in fluid control and atomization. PZT discs can be used to create tiny pumps or valves that control the flow of liquids with great precision. In ink jet printers, for example, PZT actuators are used to eject tiny droplets of ink onto the paper. They can also be used in medical devices to deliver precise doses of medication. In atomization, the rapid vibration of a PZT disc can break a liquid into a fine mist. This is used in humidifiers, nebulizers, and fuel injectors. The frequency and amplitude of the vibration can be tuned to control the size of the droplets produced.

PZT discs offer a unique combination of precision, speed, and compactness, making them a great choice for applications requiring controlled mechanical motion. While challenges exist in terms of durability and environmental impact, ongoing research is expanding their capabilities and addressing these concerns.

PZT Discs in Medical and Healthcare Devices

PZT discs have really made a splash in the medical field, and it’s easy to see why. Their ability to convert electrical energy into mechanical motion, and vice versa, opens up a ton of possibilities for both diagnostics and treatment. From getting a clearer picture inside the body to delivering drugs more effectively, PZT discs are changing the game.

Ultrasound Imaging and Diagnostics

Okay, so everyone’s probably heard of ultrasound, right? Well, PZT discs are at the heart of it. They generate the sound waves that bounce off tissues and create those images we see. The cool thing is, by tweaking the frequency and intensity of the waves, doctors can get different kinds of information. For example:

- High-frequency ultrasound gives really detailed images of shallow tissues.

- Lower frequencies can penetrate deeper, which is great for looking at organs.

- Doppler ultrasound uses the shift in frequency to measure blood flow.

Ultrasound is non-invasive and doesn’t use ionizing radiation, making it a safe and versatile tool for everything from prenatal checkups to diagnosing heart conditions. The precision offered by PZT medical applications is a big reason why it’s so widely used.

Therapeutic Applications of PZT

It’s not just about seeing what’s going on inside; PZT discs can also be used to do things. High-intensity focused ultrasound (HIFU) is one example. It’s like using a magnifying glass to focus sunlight, but with sound waves. This focused energy can be used to:

- Ablate tumors without surgery.

- Break up kidney stones.

- Stimulate tissue regeneration.

Another area is physiotherapy, where lower-intensity ultrasound can help with pain relief and healing. It’s pretty amazing how sound waves can be used to treat such a wide range of conditions.

Drug Delivery Systems

Getting drugs to the right place in the body, at the right time, is a huge challenge. PZT discs are being explored as a way to improve drug delivery. Here’s how:

- Nebulizers: PZT atomizers are widely used in the medical field. They are essential in devices like nebulizers, which help patients inhale medication in the form of a mist.

- Micro-pumps: Tiny PZT-driven pumps can deliver precise doses of medication directly to a specific area.

- Sonoporation: Ultrasound can temporarily disrupt cell membranes, allowing drugs to enter more easily.

These techniques could make treatments more effective and reduce side effects. It’s an exciting area with a lot of potential for future development. The use of piezoelectric tubes in drug delivery is an area of active research.

Industrial and Commercial Applications of PZT Discs

PZT discs aren’t just lab curiosities; they’re workhorses in a bunch of industrial and commercial settings. Their ability to convert mechanical stress into electrical signals, and vice versa, makes them super useful. Let’s look at some examples.

Ignition Systems and Gas Lighters

Ever wondered how those gas lighters work without batteries? It’s PZT! A quick press generates a spark. PZT discs are used to create the high voltage needed to ignite the gas. They’re reliable, simple, and last a long time. You’ll find them in:

- BBQ lighters

- Gas stoves

- Welding torches

Sound Generation and Transducers

PZT discs are great at making sound and detecting it. They’re used in all sorts of audio equipment. Think about it:

- Speakers: PZT vibrates to create sound waves.

- Microphones: Sound waves vibrate the PZT, generating an electrical signal.

- Ultrasonic cleaners: High-frequency sound waves from PZT clean delicate parts.

PZT transducers are also used in sonar systems to send and receive sound waves underwater. This is useful for mapping the ocean floor, finding objects, and even communicating with submarines. The versatility of PZT in sound applications is pretty impressive.

Non-Destructive Testing

This is where PZT discs really shine. Non-destructive testing (NDT) means checking if something is broken without breaking it. PZT discs can send ultrasonic waves into materials. By analyzing how those waves bounce back, you can find cracks, voids, or other defects. Common uses include:

- Inspecting welds in pipelines

- Checking for flaws in aircraft parts

- Examining concrete structures

Here’s a simple table showing the effectiveness of PZT in NDT:

| Material | Defect Size Detected | Accuracy |

| Steel | 1mm | 95% |

| Aluminum | 0.5mm | 90% |

| Concrete | 5mm | 80% |

It’s all about sending sound waves and listening for the echoes. It’s like piezoelectric materials using sound to

Emerging Trends and Future Prospects for PZT Discs

The world of PZT discs is far from static. New developments are constantly pushing the boundaries of what these versatile components can achieve. From material science to innovative applications, the future looks bright for PZT technology. Let’s explore some of the exciting trends on the horizon.

Development of Lead-Free PZT Alternatives

One of the biggest challenges facing the PZT industry is the presence of lead in traditional PZT materials. Lead poses environmental and health risks, driving research into lead-free alternatives. Scientists are actively exploring new compositions and manufacturing processes to create PZT discs that are both high-performing and eco-friendly. This includes materials like bismuth sodium titanate (BNT) and potassium sodium niobate (KNN). The goal is to find a replacement that matches the piezoelectric properties of lead-based PZT without the associated environmental concerns. This is a big deal for applications where environmental regulations are becoming stricter.

Miniaturization and Integration

Smaller is often better, especially in modern electronics. The trend toward miniaturization is also impacting PZT discs. Researchers are developing techniques to create smaller, thinner PZT elements that can be easily integrated into micro-devices and systems. This involves advanced microfabrication methods and new designs that optimize performance at a smaller scale. Think about the possibilities for implantable medical devices or ultra-compact sensors. This push for smaller devices is opening up new avenues for piezoelectric transducer technology.

Here’s a quick look at how miniaturization is progressing:

- Improved microfabrication techniques

- Development of thin-film PZT

- Integration with MEMS (Micro-Electro-Mechanical Systems)

Smart Materials and Adaptive Systems

Imagine materials that can sense their environment and respond accordingly. That’s the vision behind smart materials, and PZT discs are playing a key role. By integrating PZT discs with sensors and control systems, it’s possible to create adaptive systems that can adjust their behavior in real-time. For example, a smart structure could use PZT actuators to dampen vibrations or change its shape in response to external forces. This opens up exciting possibilities in aerospace, automotive, and civil engineering. The development of smart materials is a game changer.

The future of PZT discs lies in their ability to become more integrated, more sustainable, and more responsive. As research continues and new applications emerge, we can expect to see PZT technology playing an increasingly important role in a wide range of industries.

Challenges and Considerations in PZT Disc Implementation

While PZT discs offer a wide array of benefits, successfully integrating them into real-world applications isn’t always a walk in the park. There are several hurdles to consider, from ensuring the material can withstand the operating environment to navigating the complexities of design and fabrication. Plus, we can’t ignore the environmental impact. Let’s break down some key challenges.

Durability and Performance Under Stress

PZT materials, while robust, aren’t invincible. Their performance can degrade over time, especially when subjected to continuous stress, high temperatures, or strong electric fields. This degradation can manifest as a decrease in piezoelectric coefficient, leading to reduced sensitivity or actuation force. Factors affecting durability include:

- Mechanical stress (compression, tension, shear)

- Electrical stress (high voltage, alternating fields)

- Temperature variations

- Humidity and corrosive environments

It’s important to carefully consider the operating conditions when selecting a PZT material and designing the application. Proper mounting techniques and protective coatings can help mitigate the effects of stress and extend the lifespan of the PZT disc.

Design and Fabrication Complexities

Designing with PZT discs isn’t as simple as dropping them into a circuit. The electromechanical coupling requires careful consideration of impedance matching, resonance frequencies, and mechanical boundary conditions. Fabrication can also be tricky, especially when dealing with complex shapes or tight tolerances. Some common design and fabrication challenges include:

- Achieving desired resonant frequencies

- Minimizing parasitic capacitance

- Ensuring uniform polarization

- Bonding PZT to other materials without introducing stress

To address these challenges, simulation tools and finite element analysis are often used to optimize the design. Precision machining and bonding techniques are also essential for achieving reliable performance. It’s important to evaluate PZT suppliers to ensure you get the best materials.

Environmental Impact and Sustainability

Traditional PZT materials contain lead, which is a toxic substance. The environmental impact of lead-based ceramics is a growing concern, driving research into lead-free alternatives. While lead-free PZT materials are emerging, they often have lower piezoelectric coefficients or other trade-offs. Considerations for environmental impact include:

- Lead content in traditional PZT materials

- Energy consumption during manufacturing

- Disposal and recycling of PZT components

- Development of lead-free alternatives

Researchers are actively exploring new materials and manufacturing processes to reduce the environmental footprint of PZT technology. This includes investigating bismuth-based ceramics, alkali niobates, and other promising candidates. The goal is to find materials that offer comparable performance to lead-based PZT while minimizing environmental risks. High-performance piezoelectric material is important for many applications.

Working with PZT discs can be tricky, but knowing the common problems helps a lot. Things like making sure they’re put in correctly and dealing with how they react to heat are super important. If you want to learn more about these challenges and how to handle them, check out our website. We have lots of helpful information there!

So, to wrap things up, PZT discs are pretty amazing. They show up in all sorts of places, from tiny medical gadgets to big industrial machines. It’s wild how one little component can do so much. We’ve seen how they help with things like making sounds, sensing stuff, and even creating precise movements. They really are a big part of what makes a lot of today’s tech work. And honestly, it feels like we’re just scratching the surface of what these discs can do. As technology keeps moving forward, you can bet PZT discs will be right there, helping to make new things possible. It’s going to be interesting to see where they pop up next!

Frequently Asked Questions

What exactly is a PZT disc and how does it work?

PZT discs are special materials that change shape when electricity is applied, and create electricity when they are squeezed or stretched. This makes them super useful for many different tools and machines.

Where are PZT discs commonly used today?

PZT discs are used in many cool ways! They can make sound, like in speakers, or listen for sounds, like in microphones. They also help in medical devices like ultrasound machines to see inside the body, and even in lighters to create a spark.

What are some difficulties in using PZT discs?

One big challenge is making them last a long time, especially when they are used over and over again or in tough conditions. Also, making them very small and fitting them into new devices can be tricky.

Are there new kinds of PZT discs being developed?

Yes, they are! Scientists are working on new types of PZT materials that don’t use lead, which is better for our planet. They are also trying to make them even smaller and smarter so they can do more amazing things.

How do PZT discs help in medical tools?

In healthcare, PZT discs are key for ultrasound imaging, helping doctors see babies before they are born or check on organs. They are also used in some treatments and even in new ways to deliver medicines inside the body.

How are PZT discs used to detect things?

PZT discs are great at sensing tiny changes, like pressure or vibrations. This makes them perfect for things like earthquake detectors, or systems that check if a building is shaking, or even in touch screens.