Piezoelectric Ceramics in Aerospace Applications

Piezoelectricity is undoubtedly one of the most beneficial and efficient means of generating power in virtually any environment. The electricity generated via piezoceramic material can be harnessed to generate movement or produce electrical signals. In recent years, space exploration has made large strides in the implementation of piezo sensors and piezo actuators in aerospace applications. Operating and data gathering in space presents an array of difficulties in an uncontrollable environment, however, piezoelectric sensors and piezoelectric actuators are favored for their immediate response time and low power consumption. The expanding use of piezoelectric ceramics in space allows for fuel preservation, satellite control, atmospheric particle readings, and much more.

As space is increasingly explored, there is a massive drive to understand this new environment. For years, NASA has been testing the viability of utilizing piezo sensors for impact detection of space particles and debris. Given the capabilities of piezo elements, NASA designed an impact piezoceramic sensor to detect micrometeoroids and sub-millimeter orbital debris that cannot usually be tracked. The impact piezo sensors work by utilizing thin piezo strips or piezo plates. When space debris collides with the piezoelectric sensor, the particle impact generates vibrational waves on the piezo strip or piezo plate. The vibrational movement from the debris impact produces an electrical signal that is proportional to the strain applied, allowing the piezo sensor to capture the location of the impact and use that information to identify speed and directional information. The proportional electrical charge generated by the impact can also be used to determine the particle material and density. Overall, the impact detection afforded by piezoceramic sensors opens doors to gathering a comprehensive understanding of the environment in space.

While there is still much to explore and learn in space, piezoceramics, specifically piezo actuators, can and have offered massive improvements to many aerospace applications, from satellite control to jet propulsion. Take satellite communication, for example. Typical RF signals and fiber optic networks have bandwidth and precision limitations. One solution has been developing inter-satellite laser beam communications. SpaceX recently launched over a hundred laser-equipped satellites, with each satellite tracking and linking to the others via inter-satellite laser links. Piezoelectric actuators, such as piezoelectric tubes, offer most precise displacement and control for controlling these lasers to achieve sufficient communication. Laser beams must maintain an exact path to achieve satellite links, and piezo actuators and produce extremely fast and precise responses to keep the beam on target. Atmospheric turbulence and other factors can shift the beam from its path, but piezo actuators like piezo tubes are able to perform rapid and accurate adjustments in response to disturbances in the environment.

In other non-laser satellites, piezo actuators, mainly piezo stacks, can be used for jet propulsion or micro-thrusters to position the satellite correctly. Multilayer piezo stack actuators provide accurate and precise control and release of fuel or propellant. Piezo stacks can achieve very small displacement. When a signal is received, the piezo actuator opens a valve to dispense a precise amount of fuel that can be used to position or stabilize the satellite. Piezo actuators of all shapes, including piezo tubes and piezo stacks, are preferred for providing fast and precise response for satellite control in a small package.

Piezoelectric ceramics offer a lens into the unknown in space. Piezo elements, as aerospace engineers are discovering, are the ideal tool for measuring the environment and controlling devices due to their extremely precise, accurate, and fast response. Piezo sensors and piezo actuators are now at the forefront of aerospace applications, and piezoelectric ceramics will inhabit space for long to come.

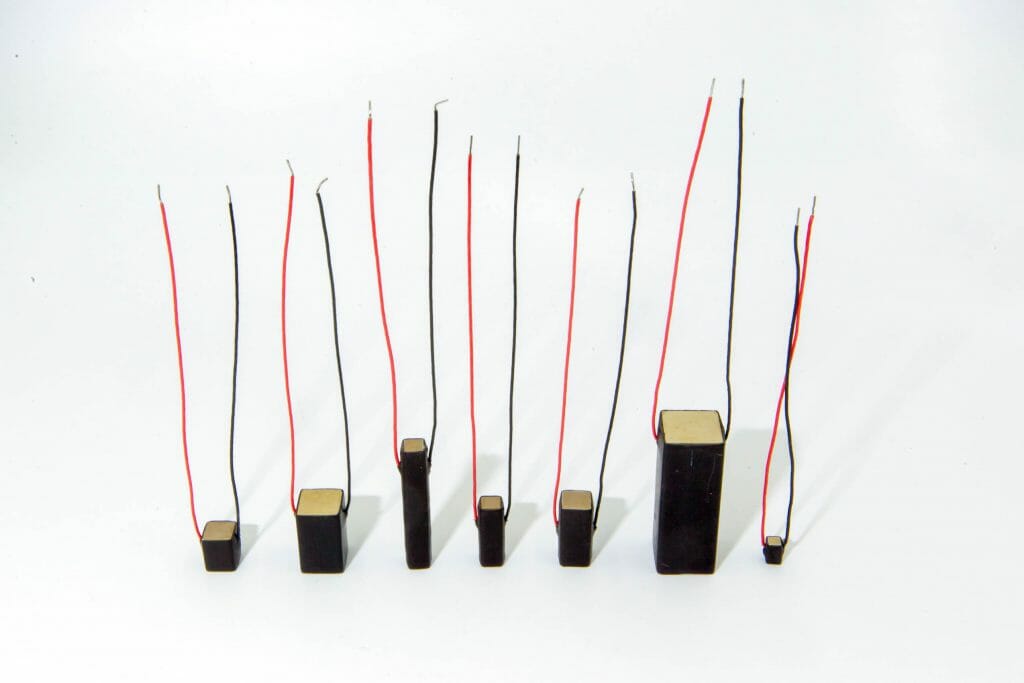

For custom piezoceramics, please contact Piezo Direct at 650-375-7003 or [email protected] for more information. Piezo Direct is an experience partner is designing and manufacturing custom piezoelectric sensors and actuators, including piezo plates, piezo strips or piezo bending actuators, piezo tubes, and piezo stack actuators.