Piezoceramic materials are incredibly versatile and find use in a wide range of engineering applications. Their ability to convert mechanical energy into electrical energy and vice versa makes them indispensable in many fields.

Medical Devices

Piezoceramics are crucial in medical devices, especially in ultrasound equipment. They help generate sound waves that create images of the inside of the body. These materials are also used in precision surgical tools, enhancing their effectiveness and accuracy.

Aerospace Technologies

In aerospace, piezoceramics are used in various sensors and actuators. They help monitor and control different aspects of aircraft performance, ensuring safety and efficiency. Their ability to withstand extreme conditions makes them ideal for this industry.

Ultrasonic Cutting Devices

Piezoceramic materials are also used in ultrasonic cutting devices. These devices are essential in industries that require precise cutting, such as electronics and medical fields. The piezoceramics enable these tools to cut with high precision and minimal damage to the materials being cut.

Advancements in Piezoceramic Materials

Lead Zirconate Titanate (PZT)

Lead Zirconate Titanate, commonly known as PZT, is a standout in the world of piezoceramics. Thanks to their high piezoelectric properties, PZT ceramics are widely used in many devices, from medical imaging tools to energy harvesters. Researchers are constantly working to improve PZT ceramics to meet the growing demands of modern technology.

Lead-Free Piezoceramics

With the increasing concern over the environmental impact of lead, scientists are developing lead-free piezoceramics. These materials aim to offer similar or even better performance compared to their lead-based counterparts. The challenge lies in finding a balance between performance and environmental safety.

Material Improvements

Recent advances in piezoelectric materials have led to significant improvements in their properties. These include better temperature stability, enhanced electromechanical response, and increased durability. Such improvements make piezoceramics more reliable and efficient for various applications.

The journey of piezoceramics from their early days to modern advancements showcases the relentless efforts of scientists to push the boundaries of material science.

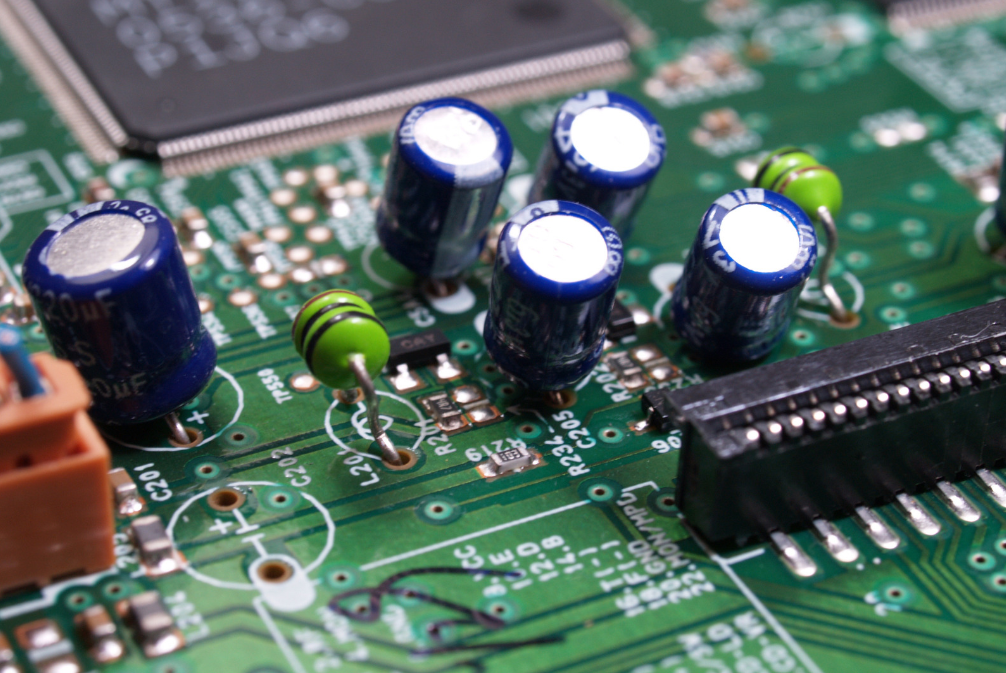

Manufacturing and Shapes of Piezoceramic Materials

Piezoceramic materials are crafted into various shapes to meet the needs of different applications. These shapes are essential for their performance in energy conversion devices, where they turn electrical signals into mechanical vibrations. Manufacturing these materials requires precision and expertise.

Electromechanical Properties of Piezoceramics

Coupling Mechanisms

Piezoceramic materials are known for their unique ability to couple mechanical and electrical fields. This electromechanical coupling is essential in devices like transducers, actuators, and sensors. Single crystals of piezoelectric materials generally show a stronger electromechanical response compared to polycrystalline ceramics. However, ceramics are easier to manufacture into various shapes and sizes, making them widely used in the industry.

Temperature Range and Stability

The performance of piezoceramics can be affected by temperature. These materials need to maintain stability across a wide temperature range to be effective in different applications. The dielectric, piezoelectric, and mechanical properties of piezoceramics can change with temperature, which can impact their overall performance.

Electromechanical Response

The electromechanical response of piezoceramics is characterized by their ability to convert electrical energy into mechanical energy and vice versa. This response is measured by evaluating the dielectric, piezoelectric, and mechanical losses. These losses can lead to issues like hysteresis in positioning actuators and heat generation in resonance applications like ultrasonic motors. Despite these challenges, piezoceramics remain suitable for a variety of applications due to their unique properties.

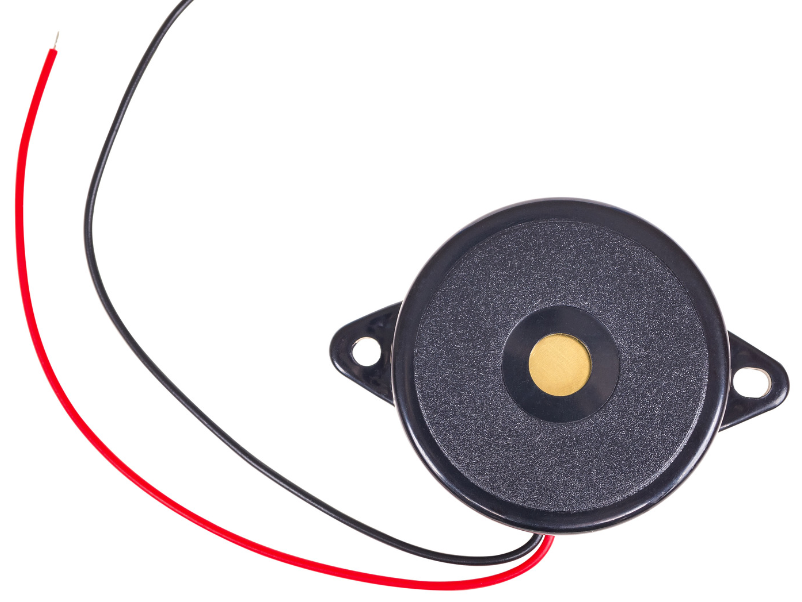

Role of Piezoceramics in Sensor Technology

Piezoceramic materials are essential in the world of sensors. Their unique ability to interact with mechanical, electrical, and thermal forces makes them indispensable in advancing material technology. In numerous sensor applications, piezoceramic elements play a vital role in the detection and measurement of specific signals.

Challenges and Solutions in Piezoceramic Applications

Brittleness and Damage

Piezoceramic materials are known for their brittleness, which makes them prone to damage. This can limit their use in applications where durability is crucial. Potential solutions to overcome this challenge include advancements in 3D printing techniques and process optimization. These improvements can help create more robust piezoceramic components.

Conformation to Curved Surfaces

Another challenge is getting piezoceramic materials to conform to curved surfaces. This is important for applications in medical devices and aerospace technologies. Flexible substrates and innovative bonding techniques are being developed to address this issue, allowing piezoceramics to be used in more versatile ways.

Cytotoxicity in Biomedical Applications

In biomedical applications, the cytotoxicity of piezoceramic materials can be a concern. Researchers are working on developing lead-free piezoceramics to make them safer for use in medical devices. These new materials aim to maintain the beneficial properties of traditional piezoceramics while reducing health risks.

The ongoing research and development in piezoceramic materials are crucial for overcoming these challenges and expanding their applications in various fields.

Historical Development of Piezoceramic Materials

Early Developments

The development of piezoelectric materials began with the discovery of the direct piezoelectric effect in quartz by Pierre and Jacques Curie in 1880. This discovery led to the exploration of other materials showing similar properties. Early research focused on natural crystals, but the need for more efficient materials soon became apparent.

Evolution of Lead-Based Materials

In the 1950s, the use of barium titanate (BaTiO3) marked a significant step forward. However, it was the emergence of lead-based materials, particularly lead zirconate titanate (PZT), that revolutionized the field. PZT, with its high piezoelectric coefficients, became the archetypal material for practical applications. This period saw intense international interest and rapid development of piezoelectric devices.

Modern Research Trends

Today, research continues to advance, focusing on improving the performance and safety of piezoceramic materials. Lead-free piezoceramics have become a hot topic due to the cytotoxicity of lead-based materials. Modern studies aim to find alternatives that offer similar or better performance without the associated health risks.

The journey from the discovery of the piezoelectric effect to the development of advanced piezoceramic materials highlights the importance of continuous innovation in engineering.

Conclusion

In summary, piezoceramic materials have become essential in modern engineering, finding uses in everything from medical devices to aerospace technologies. Their unique ability to convert mechanical energy into electrical energy and vice versa makes them invaluable in many fields. As technology continues to advance, the demand for these versatile materials will only grow. We hope this article has provided a clear understanding of the importance and applications of piezoceramics in today’s world.

Frequently Asked Questions

What are piezoceramic materials used for?

Piezoceramic materials are used in many fields like medical devices, aerospace technologies, and ultrasonic cutting tools. They help convert mechanical energy into electrical energy and vice versa.

What shapes can piezoceramic materials be made into?

Piezoceramic materials can be made into different shapes like cylinders, disks, rods, hemispheres, and spherical caps.

Why is Lead Zirconate Titanate (PZT) important?

Lead Zirconate Titanate (PZT) is important because it has strong piezoelectric properties, making it useful in many devices like medical imaging tools and energy harvesters.

What are the challenges of using piezoceramic materials?

Some challenges include their brittleness, difficulty conforming to curved surfaces, and potential cytotoxicity in biomedical applications.

How have piezoceramic materials changed over time?

Piezoceramic materials have evolved from early developments to modern lead-based materials and are still being researched for new improvements.

What role do piezoceramics play in sensor technology?

Piezoceramics are key components in sensors like ultrasonic transducers, microdisplacement devices, and accelerometers due to their ability to interact with mechanical and electrical forces.