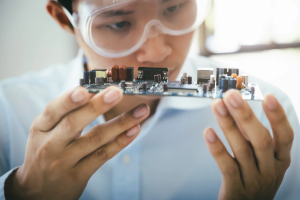

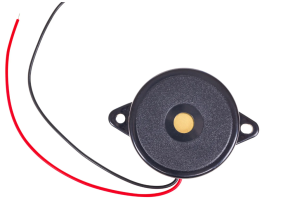

Your Engineering Partner for Precision Piezoelectric Components

Piezo Direct is a dedicated piezoelectric manufacturer and supplier specializing in high-performance piezoelectric components for critical applications. With a focus on both standard products and