What Are Piezo Atomizers?

Piezoceramics are often used to atomize liquid and fluid solutions through ultrasonic vibrations. Piezo atomizers follow the same principle as piezo transducers by creating a mechanical response to an electrical input. Ultrasonic vibration in piezoelectric sensors and piezoelectric transducers are generated by converting an electrical charge (AC voltage) into a vibration movement.

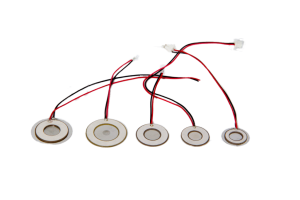

Let’s take a closer look at the component parts of a piezoelectric atomizer. Piezo atomizers are used to atomize liquid, creating and dispensing mist that can be found in nebulizers, fragrance dispensers, or cleaning devices. The fluid solution is placed in a reservoir, surrounded by a piezo element, usually a piezo disc. A perforated mesh disc with many tiny holes is places on top of the liquid reservoir and piezo element. When an electrical voltage is applied to a piezo atomizer, the piezo element generates ultrasonic frequencies. The rapid ultrasonic vibration from the piezoceramic causes the fluid to be pushed through the mesh disc, producing tiny droplets or mist. The micron-size droplets produced by the piezoelectric atomizer are extremely uniform in size and distribution due to the mesh disc, making it a valuable component in medical and commercial applications. The number of holes and size of holes in the mesh disc is a key factor in determining the droplet size and flow rate.

An excellent example of piezo atomizers in action can be seen in a commonly used medical device – nebulizers. Nebulizers, often used to treat asthma, delivers medicine through tiny aerosols that are inhaled. Piezoelectric atomizers or ultrasonic piezoelectric transducers are used to generate vibrations and produce droplets. One benefit of piezo atomizers is the ability to produce very small droplets that can safely and effectively be inhaled. When an electrical signal is received by the atomizer, the piezo element will begin to oscillate at ultrasonic frequencies. The rapid oscillation pushes the medicine through the mesh layer to be delivered to the lungs. The droplet size is predefined by the size and number of holes in the mesh layer and there is minimal energy involved. Piezo discs as piezo atomizers are widely used for nebulizers and aerosol generation in medicine. The small droplet sizes needed for safe inhalation is accurately and consistently achieved by piezoelectric ceramics. The very fine particle sizes and long life of ultrasonic piezo transducers makes piezo atomizers ideal in medical applications.

Piezo atomizers can also produce larger droplets that are commonly seen in aroma diffusers and humidifiers. Ultrasonic oscillation disrupts the surface of the fluid with mechanical vibrations that forces the fluid to break apart into small droplets, expelled through the mesh layer on the piezo element. Piezoceramic atomizers are ideal for commercial diffusers, humidifiers, and sprayers that require various levels of output depending on application. E-cigarettes and vaping devices also rely on piezoceramics to achieve safe droplet sizes for commercial devices. Consistent predefined droplet sizes, long life, no audible noise, and the lightweight and compact nature of piezo atomizers make them ideal piezoceramics for air humidifiers, aroma diffusers, paint sprayers, and much more.

Piezo atomizers, along with any piezoelectric ceramic product from Piezo Direct, allow for endless customization to achieve the exact droplet size and output needed for many medical and commercial applications. Piezo Direct is a trusted piezoelectric company that offers a wide range of piezoelectric products, including fully customizable piezo actuators, piezoelectric sensors, and piezo transducers, available in a variety of shapes. For more information about Piezo Direct’s fully custom capabilities and piezoelectric ceramics, please contact Piezo Direct at 650-375-7003 to learn more about custom piezo elements.