The Foundation of Piezoelectric Conversion

So, how does this whole piezoelectric thing actually work? It’s all about materials that have a special kind of atomic structure. Think of it like tiny, organized building blocks. When you apply some pressure or mechanical stress to these materials, their internal structure gets a little squished or stretched. This deformation causes a separation of positive and negative electrical charges within the material. It’s this charge separation that creates a voltage, a sort of electrical potential difference. This effect is called the direct piezoelectric effect. It’s pretty neat because it means you can generate electricity just by bending, pressing, or vibrating certain materials. This is the core idea behind using piezoelectricity in flexible devices – turning physical movement into usable electrical energy.

Mechanical Stimuli to Electrical Signals

When we talk about flexible devices, we’re often thinking about things that bend, stretch, or get bumped around. These are the mechanical stimuli. Piezoelectric materials are fantastic because they can take these physical actions and turn them into electrical signals. Imagine a flexible sensor in a wearable device. When you move your arm, the sensor bends. This bending causes the piezoelectric material inside to generate a small electrical charge. This charge can then be measured and interpreted as a signal, telling the device that movement has occurred. It’s a direct conversion: physical force becomes an electrical output. This makes them really useful for sensing things like pressure, vibration, and even impact.

Leveraging Non-Centrosymmetric Structures

The magic behind piezoelectricity really comes down to the internal arrangement of atoms within a material. Specifically, piezoelectric materials need to have a non-centrosymmetric crystal structure. What does that mean? Basically, if you try to find the center of the crystal and reflect it through that center, the structure doesn’t look the same. This asymmetry is what allows for the charge separation when the material is deformed. Without this specific structural property, the charges would just rearrange themselves symmetrically, and you wouldn’t get that useful electrical output. Many ceramics and some polymers naturally have this property, which is why they are often chosen for piezoelectric applications. It’s this inherent molecular architecture that makes the piezoelectric effect possible.

Advancements in Piezoelectric Materials for Flexibility

From Inorganic Ceramics to Organic Polymers

When we first started looking at piezoelectric materials, a lot of what we found were inorganic ceramics. Think materials like Barium Titanate (BTO) or Lead Zirconate Titanate (PZT). These guys are known for their strong piezoelectric effect, meaning they convert mechanical stress into electrical charge really well. However, they tend to be brittle. That’s not ideal when you need something that can bend and flex without breaking, especially for wearable tech or devices that get moved around a lot. So, the industry started looking elsewhere. This led to a big shift towards organic polymers. Polyvinylidene Fluoride (PVDF) and its copolymers have become super popular. They’re naturally flexible, lightweight, and can be processed into thin films. This flexibility is key for integrating them into all sorts of devices that need to conform to different shapes.

The Role of Piezoelectric Composites

Just using a single material often means you have to compromise. You might get flexibility but not the strongest electrical output, or vice versa. That’s where composites come in. By mixing different materials, we can try to get the best of both worlds. Imagine taking a flexible polymer like PVDF and adding tiny particles of a ceramic piezoelectric material. The polymer gives it the bendability, and the ceramic particles boost the electrical signal. It’s like adding a turbocharger to your flexible sensor. We’ve seen a lot of work done with PVDF combined with things like BTO or zinc oxide (ZnO) nanoparticles. The way these particles are arranged and how well they stick to the polymer matrix makes a big difference in how much power you can get out of it.

Enhancing Performance with Nanomaterials

Going even smaller, nanomaterials have really opened up new avenues. We’re talking about things like carbon nanotubes (CNTs) or even modified versions of existing materials at the nanoscale. For example, adding carbon nanotubes to PVDF can significantly increase its voltage output compared to just using PVDF alone. It’s not just about adding more material; it’s about how these tiny structures interact. Sometimes, surface modifications are used too. Take polydopamine (PDA), for instance. Coating piezoelectric particles with PDA can improve how they disperse within a polymer and even boost their piezoelectric properties. This allows for more sensitive and robust sensors that can pick up even subtle movements or pressures.

Material Innovations for Enhanced Piezoelectric Output

Utilizing Barium Titanate and PVDF Composites

When we talk about making piezoelectric materials work better in flexible devices, a lot of the progress comes from mixing different things together. One common approach is to combine barium titanate (BTO) with polymers like polyvinylidene fluoride (PVDF). BTO is a ceramic that’s really good at being piezoelectric, but it’s brittle. PVDF, on the other hand, is flexible. By creating a composite, you can get the best of both worlds. Researchers have found that adding BTO particles to a PVDF matrix can significantly boost the piezoelectric output. For example, one study showed a composite membrane that produced a voltage of 9.3 V when a force of 12 N was applied. That’s a big jump compared to just using PVDF by itself.

Carbon Nanotubes for Increased Voltage Generation

Another material that’s making waves in this area is carbon nanotubes (CNTs). These tiny tubes of carbon have some pretty amazing electrical and mechanical properties. When you mix CNTs into a material like PVDF, they can help improve how well the material generates electricity when it’s squeezed or bent. Think of it like adding a superhighway for electrical charges. One team created a PVDF foam mixed with CNTs and got an output voltage of around 12 V under a small pressure. Compare that to a simple PVDF film, which might only give you about 4 V under similar conditions. It really shows how adding these nanomaterials can make a difference.

Exploring Polydopamine Modifications

Sometimes, just mixing materials isn’t enough. You might need to treat the materials first to make them work even better together. Polydopamine (PDA) is one such treatment that’s been used. It’s a type of coating that can be applied to particles like BTO before they’re mixed into the PVDF. This PDA coating can help the BTO particles stick better to the PVDF and also improve the overall electrical properties of the composite. This kind of surface modification can lead to more consistent and higher piezoelectric responses, which is exactly what we need for reliable flexible electronics. It’s a bit like prepping a surface before painting – it makes the final result much better.

Structural Design Strategies for Piezoelectric Sensors

The Impact of Nanofiber Architectures

When we talk about making piezoelectric sensors more sensitive and effective, the way we build them matters a lot. One really interesting approach is using nanofibers. Think of them as super-thin threads. When you arrange these nanofibers in specific ways, like aligning them, you can really boost how well the sensor works. For example, researchers have created sensors using nanofibers made from materials like PVDF (polyvinylidene fluoride) and ZnO (zinc oxide).

These nanofiber structures can be designed in different ways. Some are just randomly arranged, while others are carefully aligned. The aligned ones tend to perform better because the piezoelectric effect is more consistent across the material. This can lead to a significant jump in how much electrical signal you get from the same amount of mechanical force. It’s like getting more bang for your buck, or in this case, more voltage for your pressure.

Micro-pillar and Pyramid Structures

Beyond nanofibers, other structural designs are also showing promise. Imagine building tiny pillars or pyramid shapes on the sensor’s surface. These structures can help concentrate mechanical stress onto the piezoelectric material. This means even a small amount of pressure or bending can create a stronger electrical output.

For instance, using a material like P(VDF-TrFE) (a type of PVDF copolymer) in a micro-pillar array has shown a big improvement in piezoelectric performance compared to a flat film of the same material. It’s like having many tiny amplifiers working together. Similarly, pyramid shapes can also guide and amplify the mechanical input, leading to a more robust signal. These designs are all about optimizing how the mechanical force is applied to the piezoelectric material.

Hierarchically Interlocked Designs

Now, let’s talk about something a bit more complex: hierarchically interlocked designs. This is where you combine different structural elements at various scales to create a really sophisticated sensor. Think of it like building with LEGOs, but on a microscopic level. You might have a base structure with larger features, and then on top of that, you have smaller, interlocking components.

One example involves creating a 3D structure where nanofibers are arranged in a way that they interlock with each other. This kind of design can significantly increase the sensor’s sensitivity. It’s not just about the material itself, but how it’s put together. This intricate arrangement can lead to a much higher signal output, sometimes several times better than simpler designs.

Here’s a quick look at how some of these structures compare:

| Structure Type | Material Example | Performance Improvement (Relative) | Notes |

| Nanofiber Membrane | PVDF Nanofibers | Up to 6x | High signal-to-noise ratio |

| Micro-pillar Array | P(VDF-TrFE)/BTO Nano-composite | 7.3x | Improved piezoelectric performance |

| Pyramid Film | P(VDF-TrFE) | Ultrasensitive response | Responds well to deformation |

| Hierarchically Interlocked | PVDF/ZnO Nanofibers | Significantly improved sensitivity | Complex 3D arrangement |

The way a piezoelectric sensor is physically structured plays a huge role in its performance. It’s not just about picking the right material; it’s about engineering the material’s form to best capture and convert mechanical energy into electrical signals. Different shapes and arrangements can amplify weak forces or distribute stress more effectively, leading to more sensitive and reliable sensors.

Applications of Using Piezo Strips in Flexible Devices

Self-Powered Wearable Sensors for Healthcare

Flexible piezoelectric sensors are really starting to make waves in healthcare. Think about it: devices that can monitor your body’s signals without needing batteries. This is a big deal for long-term patient monitoring. These sensors can pick up on subtle movements and vibrations, turning them into electrical energy that powers the sensor itself. This means continuous, non-invasive tracking of vital signs or even early detection of certain conditions. For instance, a flexible strip integrated into a bandage could monitor wound healing by detecting subtle changes in movement or pressure. The ability to harvest energy from the body’s own motion makes these devices incredibly practical for remote or continuous care scenarios.

Gait Analysis and Human Motion Monitoring

Understanding how people move is important for everything from sports science to physical therapy. Piezoelectric strips are fantastic for this. They can be embedded into clothing or footwear to capture the forces and movements generated during walking, running, or other activities. This data can provide incredibly detailed insights into gait patterns, helping to identify abnormalities or track recovery progress after an injury. Imagine a physical therapist getting real-time feedback on a patient’s walking form, all from sensors in their shoes. This kind of motion monitoring is also useful for athletes looking to optimize their performance or prevent injuries. The sensors convert the mechanical stress of each step into an electrical signal, which is then analyzed to understand the dynamics of movement.

Integration into Smart Textiles and Footwear

This is where things get really interesting. Piezoelectric strips aren’t just standalone sensors; they can be woven directly into fabrics or embedded into the soles of shoes. This means your clothes or shoes could become active components of a monitoring system. For example, a smart shirt could track your breathing rate or heart rhythm by sensing the subtle movements of your chest. In footwear, these strips can monitor pressure distribution, helping to improve comfort and performance, or even detect falls in elderly individuals. The flexibility and durability of these materials mean they can withstand the rigors of daily wear and tear. This opens up possibilities for everything from athletic apparel that provides performance feedback to everyday clothing that contributes to personal health monitoring. The potential for creating truly interactive and responsive wearable technology is immense, moving beyond simple data collection to active feedback systems.

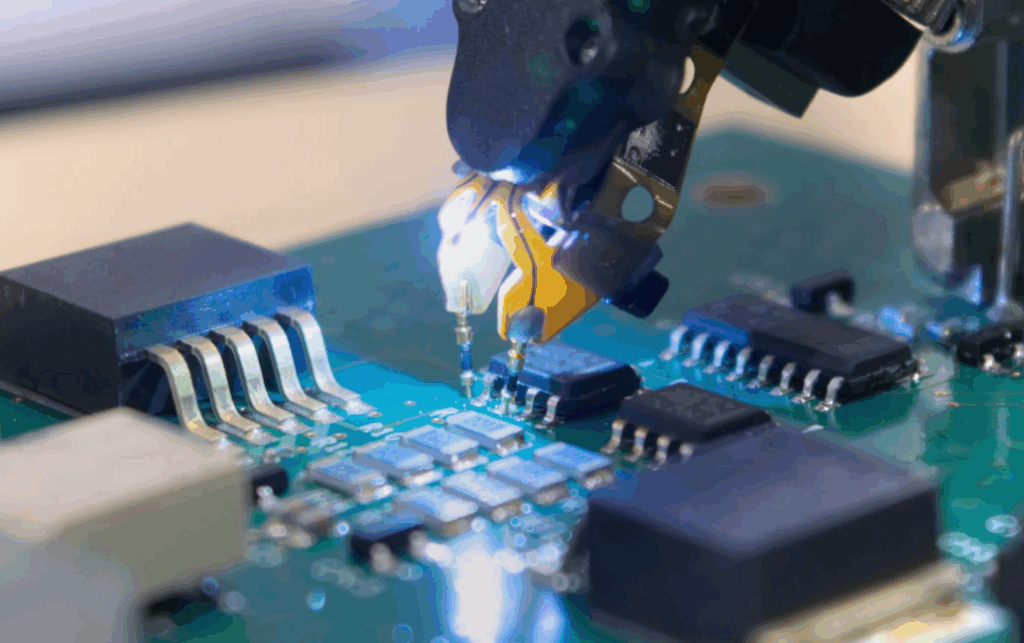

Design Considerations for Piezoelectric Integration

Integrating piezoelectric strips into flexible devices isn’t just about picking the right material; it’s about how you put it all together. Think of it like building a custom spray nozzle system – you need to consider how each part works with the others to get the best performance. Getting the mechanical interface right is key for effective energy transfer.

Optimizing Active Area and Mechanical Interface

The surface area that actually interacts with the mechanical force directly impacts how much electrical charge you can generate. A larger active area generally means more output, but it also adds bulk. You need to find that sweet spot. The way the piezo strip connects to the device’s structure is also super important. If the connection is too stiff or too loose, you won’t get efficient energy transfer. Imagine trying to spray paint with a nozzle that’s not properly seated – you get leaks and uneven coverage. For piezo strips, this means ensuring good contact without restricting the movement that causes the piezoelectric effect.

Matching Circuits for Energy Capture

Once you’ve got electricity from the piezo strip, you need to capture it effectively. This is where circuit design comes in. Piezoelectric devices often produce high voltage but low current, and the output can be irregular. You need to match the electrical load of your circuit to the output characteristics of the piezo strip. This is similar to how different spray nozzle tips are designed for specific flow rates and pressures; the circuit needs to be tuned to the piezo’s “output profile.” Without proper impedance matching, a lot of that generated energy just gets lost.

Reliable Packaging for Durability

Flexible devices often face tough conditions – bending, stretching, maybe even getting a little wet. The packaging needs to protect the delicate piezo strip while still allowing it to do its job. This means using materials that are both flexible and robust. Think about how industrial spray nozzles need to withstand high pressures and corrosive environments; the packaging for your piezo device needs similar resilience, but in a flexible form factor. It has to keep the internal components safe from damage and environmental factors without hindering the mechanical input needed for the piezoelectric effect. This often involves multi-layer designs with protective outer shells and flexible internal supports.

The Future of Piezoelectric Technology in Wearables

Enabling Low-Power IoT Devices

Piezoelectric materials are really starting to show promise for making the next generation of Internet of Things (IoT) devices much more practical, especially the ones we wear. Think about all those tiny sensors in smartwatches or fitness trackers. Right now, they often rely on small batteries that need frequent charging or replacement. Piezoelectric strips offer a way to generate their own power from everyday movements. This means devices could become truly self-sustaining, running for years without needing a battery change. This is a big deal for making IoT more widespread and less of a hassle. Imagine a world where your health monitor just powers itself by you walking around. It’s not science fiction anymore; it’s becoming a reality thanks to these flexible power sources. The ability to harvest energy from even slight body motions, like a heartbeat or a joint bending, is key to this low-power revolution.

Advancements in Energy Harvesting

We’re seeing some pretty cool developments in how effectively piezoelectric materials can capture energy. Researchers are tweaking the materials themselves and how they’re structured to get more electrical output from the same amount of mechanical input. For example, combining different materials, like polymers with tiny ceramic particles or carbon nanotubes, can significantly boost how much voltage is produced. We’re also looking at how to arrange these materials, like using special fiber structures or tiny pillars, to catch more movement. This improved energy harvesting means we can power more complex sensors or transmit data more frequently, all from the same small piezoelectric strip. It’s all about getting the most bang for your buck, or in this case, the most electricity from your movement.

Synergistic Combinations with Other Technologies

Piezoelectric technology isn’t going to work in a vacuum. The real magic will happen when it’s combined with other smart technologies. For instance, pairing piezoelectric sensors with triboelectric generators (which also harvest energy from motion) can create hybrid devices that capture even more power from a wider range of movements. This combined approach can lead to more robust and reliable self-powered systems. We’re also seeing integration with advanced materials and manufacturing techniques, like 3D printing, to create custom-shaped sensors that fit perfectly onto the body or into clothing. The goal is to create devices that are not only functional but also comfortable and unobtrusive, blending seamlessly into our lives. This synergy is what will truly push wearable tech forward.

Looking Ahead

So, we’ve seen how these flexible piezo strips are really changing the game for all sorts of devices. They can turn movement into power, which means we can make things that don’t need batteries, or at least need them a lot less. Think about smart clothes that power themselves or sensors that can tell us how we’re walking without needing a plug. The science behind it, like how materials change shape and create electricity, is pretty neat. Plus, scientists are getting better and better at making these materials stronger and more sensitive, using things like tiny particles or special structures. It feels like we’re just scratching the surface of what’s possible, and it’s exciting to think about what these little strips will enable next in our everyday tech.

Frequently Asked Questions

What exactly is a piezo strip and how does it work in flexible devices?

Imagine a special strip that can create electricity when you bend or squeeze it. That’s basically a piezo strip! It uses something called the piezoelectric effect. When you apply pressure or movement to certain materials, they generate a small electrical charge. In flexible devices, these strips are bent or stretched by your body’s movements, turning that motion into power.

Why are these piezo strips so good for flexible gadgets?

Because they’re flexible! Traditional electronics are often stiff. Piezo strips can be made from bendy materials, so they can be woven into clothes or stuck onto curved surfaces without breaking. This makes them perfect for things like smartwatches, fitness trackers, or even sensors you wear on your skin.

Can these piezo strips really power a device all by themselves?

Yes, they can! This is called ‘self-powering.’ Instead of needing a battery that runs out, these strips can generate enough electricity from your everyday movements, like walking or typing, to power small sensors or devices. It’s like getting free energy from just moving around.

What kind of things can you do with flexible devices that use piezo strips?

Lots of cool things! They can be used in wearable sensors that track your health, like your heart rate or how you’re walking. They can also be used in smart clothing to monitor your activity or even in shoes to help athletes improve their performance by analyzing their steps.

Are the materials used in these piezo strips safe and reliable?

Scientists are working hard to use safe and reliable materials. While some older piezo materials were brittle, newer ones are often flexible polymers or special combinations of materials. They are designed to last and be safe for you to wear and use.

What’s next for this technology? Where is it heading?

The future is really exciting! We’ll likely see even more advanced gadgets that can power themselves using our body’s movements. Think of tiny, low-power devices for the Internet of Things (IoT) that never need charging, or smart textiles that can do more than just keep us warm.