Piezo transducers are pretty neat devices that have become really important in a lot of different technologies. You might not see them directly, but they’re working behind the scenes in things you use every day. Basically, they’re all about converting energy from one form to another, specifically mechanical energy into electrical energy, and sometimes the other way around. It’s a pretty clever trick that opens up a lot of possibilities.

Core Principles of Piezoelectric Conversion

The main idea behind a piezo transducer is the piezoelectric effect. This is a property found in certain materials. When you apply mechanical stress – like squeezing, bending, or vibrating them – these materials generate an electrical charge. Think of it like a tiny generator that’s activated by physical force. The amount of electrical charge produced is usually directly related to how much stress is applied. This makes them really useful for measuring forces or vibrations because you can translate those physical changes into electrical signals that can be read by other electronic components.

This effect is bidirectional, too. Not only can mechanical stress create electricity, but applying an electrical voltage to the material can cause it to deform or change shape. This is called the converse piezoelectric effect, and it’s what allows piezo transducers to be used as actuators, creating precise movements from electrical signals.

Key Mechanisms in Piezo Transducer Operation

So, how does this actually happen inside the material? It all comes down to the material’s crystal structure. Piezoelectric materials have a specific atomic arrangement that lacks a center of symmetry. When mechanical stress is applied, the positive and negative charges within the crystal lattice get slightly displaced from their normal positions. This separation of charge creates an electrical dipole, and when many of these dipoles align, it results in a measurable voltage across the material.

- Stress Application: Mechanical force is applied to the piezoelectric element.

- Charge Separation: The crystal lattice deforms, causing a separation of positive and negative charge centers.

- Voltage Generation: This charge separation creates an electric field and a measurable voltage across the material.

- Converse Effect: Applying a voltage causes the material to expand or contract, producing mechanical motion.

The precise alignment and structure of the crystal lattice are what allow for this charge separation. Without this specific asymmetry, the material wouldn’t exhibit piezoelectric properties.

Materials Driving Piezoelectric Performance

Not just any material can be piezoelectric. The performance of a piezo transducer heavily depends on the material used. Historically, natural crystals like quartz were used, and they still have some applications. However, for most modern uses, especially where high performance and specific characteristics are needed, engineered ceramic materials are preferred.

- Lead Zirconate Titanate (PZT): This is probably the most common piezoelectric ceramic. It offers a good balance of piezoelectric properties, making it versatile for many sensor and actuator applications. It’s relatively inexpensive and can be manufactured in various formulations to tune its performance.

- Barium Titanate: Another ceramic material that exhibits piezoelectricity. It was one of the earlier synthetic materials used and is still relevant in some niche applications.

- Polyvinylidene Fluoride (PVDF): This is a type of plastic that shows piezoelectric properties. It’s flexible and can be made into thin films, which is useful for applications like flexible sensors or wearable devices.

- Single Crystals (e.g., Lithium Niobate): While more expensive, certain single crystals offer superior performance in terms of temperature stability and specific electrical properties, making them suitable for high-end applications like certain types of sensors or optical modulators.

Piezo Transducers in Medical and Healthcare Innovations

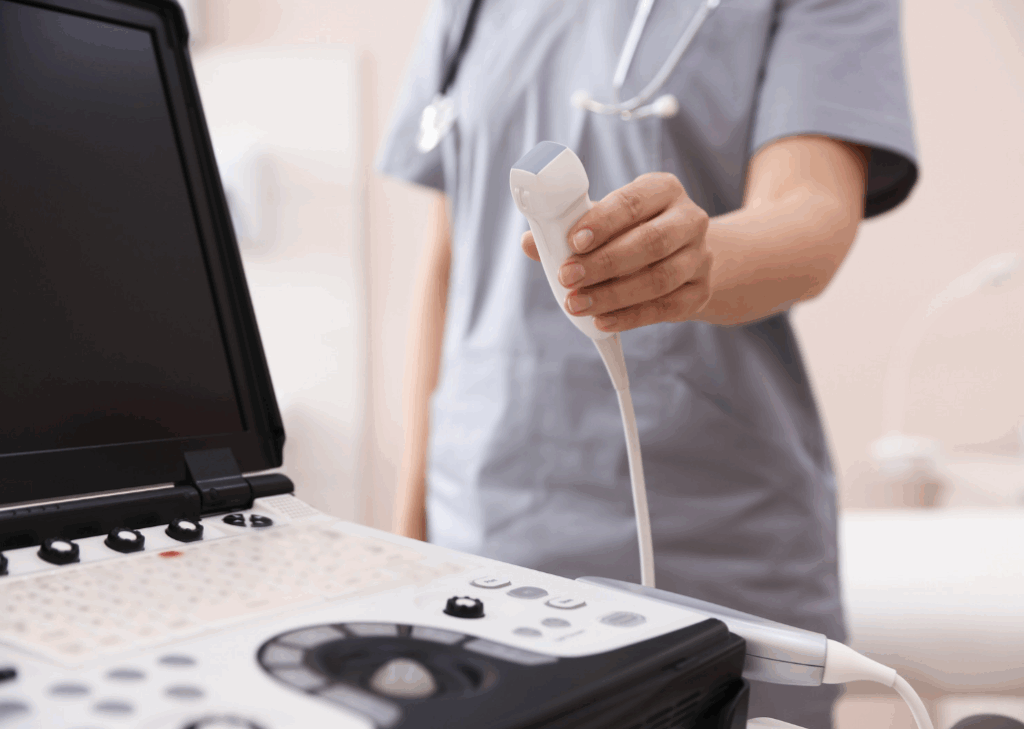

Revolutionizing Diagnostic Imaging with Ultrasound

Piezo transducers are pretty much the backbone of modern ultrasound technology. They work by sending out high-frequency sound waves and then listening for the echoes that bounce back from inside the body. This process allows doctors to see detailed, real-time images without any invasive procedures. Think about monitoring a pregnancy or checking on a heart – ultrasound makes it possible. The way these transducers work is pretty neat: an electrical signal makes the piezoelectric material vibrate, creating sound waves. When those waves hit something and bounce back, they cause the material to vibrate again, generating a new electrical signal that the machine interprets as an image. It’s a constant back-and-forth that gives us a window into what’s happening internally.

- How it works: Electrical energy -> Mechanical vibration (sound waves) -> Echoes return -> Mechanical vibration -> Electrical signal (image).

- Key benefits: Non-invasive, safe for repeated use, provides real-time visual feedback.

- Common uses: Fetal monitoring, cardiac imaging, abdominal scans, and soft tissue analysis.

The precision offered by piezo transducers in ultrasound means doctors can spot even small abnormalities, leading to earlier diagnoses and better patient outcomes. It’s a technology that’s constantly improving, giving medical professionals more powerful tools.

Enhancing Therapeutic Applications and Patient Care

Beyond just looking, piezo transducers are also getting used to treat patients. Therapeutic ultrasound, for instance, uses focused sound waves generated by these transducers to heat or break down tissue. This can be helpful in physical therapy to reduce inflammation or in breaking up kidney stones without surgery. Some research is even looking into using them for targeted drug delivery, where the ultrasound waves help push medication precisely where it’s needed in the body. This means less medicine might be needed, and side effects could be reduced.

- Physical Therapy: Focused ultrasound can help reduce pain and speed up healing in muscles and joints.

- Kidney Stone Treatment (Lithotripsy): Piezoelectric devices can generate shock waves to break stones into smaller pieces that can pass naturally.

- Drug Delivery: Emerging applications use ultrasound to improve how medications are absorbed in specific areas.

Wearable Health Monitoring and Portable Devices

It’s not just big machines anymore. Piezo transducers are showing up in smaller, wearable devices too. Imagine a wristband that can monitor your blood pressure or heart rhythm more accurately. Because these transducers can be made so small and are quite efficient, they’re perfect for portable health tech. They can pick up subtle vibrations or pressure changes from your body and convert them into data. This makes continuous health monitoring much more accessible and convenient for people, allowing for early detection of potential issues right from your home.

- Blood Pressure: Some newer devices use piezo sensors to measure pressure changes without traditional cuffs.

- Activity Tracking: Can be used to detect subtle movements and vibrations for more accurate step counting or gait analysis.

- Implantable Devices: Piezoelectric elements can even harvest small amounts of energy from body movements to power devices like pacemakers, potentially extending their lifespan.

The Role of Piezo Transducers in Consumer Electronics

Piezo transducers have really changed how we interact with our everyday gadgets. Think about your smartphone or tablet – those little vibrations you feel when you type or get a notification? That’s often a piezo transducer at work, giving you haptic feedback. It’s like the device is giving you a little tap to let you know it heard you or something happened. This technology turns tiny mechanical movements into electrical signals, and vice versa, making devices smarter and more responsive.

Elevating User Interaction with Haptic Feedback

Remember when phones just buzzed? Piezo transducers allow for much more nuanced feedback. Instead of a simple buzz, you can get different textures of vibration, making digital interactions feel more real. This is super helpful for accessibility, too, giving users with visual impairments another way to get information from their devices. It’s not just about phones; think about game controllers that rumble with the action on screen or even smartwatches that give you subtle taps to guide you.

Integrating Piezo Transducers in Smart Devices

Beyond just touch feedback, piezo transducers are showing up in more integrated ways. They can act as tiny microphones, pressure sensors, or even generate small amounts of power. For instance, some smart home devices might use them to detect subtle changes in air pressure or movement. This allows for more sophisticated automation and security features. The precision and low power needs of these components make them a good fit for the growing world of connected devices. You might even find them in things like smart locks or environmental sensors.

Applications in Mobile and Personal Technology

In our pockets and on our wrists, piezo transducers are making a difference. They contribute to the miniaturization of components, allowing for sleeker designs in everything from earbuds to fitness trackers. Their ability to convert motion into electrical energy is also being explored for self-powering devices, reducing battery dependence. Imagine a smartwatch that charges itself slightly just from the movement of your arm! This kind of innovation is key for the future of portable tech.

Piezoelectric materials are fascinating because they generate an electric charge when squeezed or stressed. This property is what makes them so useful in creating those tactile sensations we feel on our touchscreens and in other electronic devices. It’s a simple principle with complex applications.

Here’s a quick look at where you might find them:

- Haptic Feedback: Providing tactile responses on touchscreens and buttons.

- Microphones: Capturing sound in compact devices.

- Sensors: Detecting pressure, vibration, or motion.

- Energy Harvesting: Generating small amounts of power from movement.

These applications are constantly evolving, pushing the boundaries of what consumer electronics can do. For industries looking at precise fluid control, like ensuring the right amount of cleaning solution is applied, understanding how these tiny actuators work can spark ideas. For example, a nozzle that can adjust its spray pattern based on subtle pressure changes, similar to how a piezo transducer responds to touch, could offer new levels of control in applications.

| Device Type | Common Piezo Application |

| Smartphone | Haptic feedback, microphone |

| Tablet | Haptic feedback, touch sensor |

| Smartwatch | Haptic feedback, sensor |

| Game Controller | Haptic feedback |

| Wireless Earbuds | Speaker, microphone |

Piezo Transducer Applications in Automotive Systems

Boosting Safety and Performance with Advanced Sensors

Piezo transducers are becoming really important in modern cars, and it’s not just for the fancy new electric ones. Think about it: cars are getting more complex, and they need sensors that can handle tough conditions and give accurate readings. Piezoelectric sensors fit the bill because they can turn physical forces, like pressure or vibration, into electrical signals. This makes them super useful for all sorts of safety features. For instance, they can be used to monitor tire pressure in real-time, which is a big deal for preventing blowouts and improving fuel efficiency. They’re also key in advanced driver-assistance systems (ADAS), helping detect impacts or changes in road conditions.

Here are some ways they’re used:

- Engine Monitoring: Detecting knock or abnormal vibrations to keep the engine running smoothly.

- Brake Systems: Sensing pressure for better control and performance.

- Exhaust Systems: Monitoring pressure and temperature to optimize emissions control.

- Structural Health: Identifying stress or cracks in the vehicle’s frame.

These sensors are small, don’t use much power, and can be built to withstand high temperatures and vibrations, which is exactly what you need under the hood or anywhere else in a car. The ability to get precise data quickly means car manufacturers can build safer, more efficient vehicles.

Enabling Smart Tires and Vibration Control

Smart tires are a really cool application of piezo transducer technology. Imagine tires that can tell you not just their pressure, but also how much they’re wearing down or how they’re gripping the road. Piezo transducers embedded within the tire can pick up on these changes. They sense the stress and strain on the tire material as it rolls. This information can be sent wirelessly to the car’s computer, giving the driver and the car’s systems real-time insights. This can help prevent accidents caused by underinflated or worn-out tires and even adjust the car’s stability control based on grip levels.

Beyond tires, vibration control is another area where these sensors shine. Cars can get pretty noisy and bumpy, right? Piezo transducers can be used in active suspension systems. They detect unwanted vibrations and send signals to actuators that counteract those vibrations, leading to a much smoother and quieter ride. This makes long drives a lot more comfortable for everyone.

Piezo Transducers in Electric Vehicle Technology

Electric vehicles (EVs) present a unique set of challenges and opportunities for piezo transducer technology. Because EVs are so quiet, even small vibrations or noises can become more noticeable. Piezo transducers can help manage this by being integrated into systems that reduce cabin noise and vibrations. They can also play a role in battery management systems, monitoring pressure and temperature within battery packs to ensure optimal performance and safety. The precise sensing capabilities of piezo transducers are also valuable for regenerative braking systems, helping to optimize energy recovery.

Furthermore, as EVs rely heavily on sophisticated electronic systems, piezo transducers can be used for diagnostics, detecting subtle issues before they become major problems. Their low power consumption is also a significant advantage in EVs, where maximizing range is always a priority. The robust nature of these sensors means they can handle the demanding environment of a vehicle, contributing to the overall reliability and longevity of electric powertrains.

Industrial and Manufacturing Uses of Piezo Transducers

Piezo transducers are pretty handy in factories and manufacturing settings. They do a lot of jobs that need precision and reliability, often in tough conditions. Think about it: you need things to work right the first time, every time, and these little devices help make that happen.

Precision Control in Manufacturing Processes

In manufacturing, exactness is everything. Piezo transducers are used in systems that need to position things with incredible accuracy, down to the nanometer level. This is super important for things like assembling tiny electronic components or aligning parts for high-tech machinery. They can also be used to apply very specific amounts of force, which is useful in processes where too much or too little pressure would ruin the product. Their ability to make minute, controlled movements makes them ideal for automated assembly lines and robotic systems.

Non-Destructive Testing and Quality Assurance

Checking the quality of products without damaging them is a big deal. Piezo transducers are key players in non-destructive testing (NDT). They send ultrasonic waves into materials and then listen for the echoes. By analyzing these echoes, manufacturers can find hidden flaws like cracks, voids, or inconsistencies in thickness. This is used on everything from metal parts to plastics and composites. It helps catch problems early, saving money and preventing faulty products from reaching customers. It’s a way to make sure everything is up to snuff before it leaves the factory.

Ultrasonic Cleaning and Welding Applications

Ultrasonic cleaning uses high-frequency sound waves generated by piezo transducers to agitate a cleaning fluid. This creates tiny bubbles that implode, scrubbing away dirt and contaminants from even the most intricate parts. It’s way more effective than manual cleaning for delicate or complex items. Then there’s ultrasonic welding. Here, piezo transducers create high-frequency vibrations that generate heat through friction. This heat melts the surfaces of two materials, allowing them to bond together. This method is fast, clean, and works on a lot of different plastics and even some metals, making it a popular choice for high-volume production.

Here’s a quick look at some common industrial uses:

- Ultrasonic Cleaning: Removing grease, oils, and debris from parts.

- Ultrasonic Welding: Joining plastic components or films.

- Non-Destructive Testing: Detecting internal flaws in materials.

- Precision Actuation: Fine-tuning positions in automated machinery.

- Flow Measurement: Monitoring fluid movement in pipes.

Piezo transducers are often chosen for industrial tasks because they can operate reliably in environments with dust, moisture, or chemicals. Their solid-state nature means fewer moving parts to break down, which is a big plus on a busy factory floor. They also respond very quickly, which is important for real-time process control.

Vibration monitoring is another area where these transducers shine. By attaching them to machinery, you can detect unusual vibrations that might signal a problem, like a bearing going bad. This allows for predictive maintenance, meaning you can fix things before they break completely, avoiding costly downtime. It’s all about keeping the production line running smoothly.

Future Trends and Emerging Piezo Transducer Technologies

The world of piezo transducers is always moving forward, and honestly, it’s pretty exciting to see what’s next. We’re not just talking about small tweaks; there are some big shifts happening that could change how we use these devices.

Advancements in Piezoelectric Materials

One of the main areas getting a lot of attention is the materials themselves. Researchers are constantly working on new compounds and structures that can convert mechanical energy into electrical energy, and vice versa, more efficiently. Think about materials that are tougher, more sensitive, or can handle extreme temperatures better. This means piezo transducers could last longer and perform more reliably, even in tough industrial settings. For instance, new composite materials might offer a better balance of flexibility and strength, which is useful for applications where the transducer needs to bend or flex repeatedly. This push for better materials is key to making piezo tech more robust for things like advanced sensors or even more precise actuators.

Integration with the Internet of Things (IoT)

The way devices talk to each other is changing, and piezo transducers are set to play a bigger role in the Internet of Things (IoT). Imagine sensors that don’t need batteries because they can power themselves. Piezo elements can harvest small amounts of energy from vibrations or movement, turning them into electricity. This is perfect for remote sensors in smart cities, industrial monitoring systems, or even wearable health trackers. This self-powering capability is a game-changer for deploying vast networks of sensors without the hassle of constant battery replacement. It means more devices can be connected, sending data back to the cloud for analysis and action, making our environments smarter and more responsive.

Energy Harvesting Capabilities for Sustainable Tech

Following on from the IoT integration, energy harvesting is a huge trend. Piezoelectric materials are really good at capturing wasted mechanical energy – like the vibrations from machinery, the movement of vehicles, or even footsteps – and converting it into usable electrical power. This is a big step towards more sustainable technology. Instead of relying solely on batteries or grid power, we can tap into ambient energy sources. This could lead to self-powered devices that are more environmentally friendly and reduce maintenance costs. Think about sensors on bridges that monitor structural integrity, powered by the vibrations of traffic, or even small electronic devices that charge themselves as you move. It’s all about making technology more self-sufficient and less impactful on the environment.

The ongoing development in piezoelectric materials and their integration into smart systems points towards a future where devices are not only more intelligent but also more sustainable. The ability to harvest energy from everyday movements and vibrations reduces reliance on traditional power sources, paving the way for a new generation of self-powered, eco-friendly technologies.

Assessing Piezo Transducer Performance and Reliability

Key Performance Metrics for Piezo Transducers

When you’re looking at piezo transducers, especially for industrial uses like in spray nozzle systems, you need to know how well they’re actually doing their job. It’s not just about them working; it’s about how precisely and consistently they work. We’re talking about things like response time – how fast they react to a change. For many applications, this needs to be in the microsecond range, which is incredibly quick. Then there’s sensitivity, which is how well they pick up on small changes in pressure or vibration. You also want to consider their operating frequency range; can they handle the vibrations or ultrasonic frequencies needed for your specific spray application?

Here are some common metrics to keep an eye on:

- Sensitivity: How much electrical output you get for a given mechanical input (or vice versa).

- Frequency Response: The range of frequencies over which the transducer operates effectively.

- Dynamic Range: The difference between the smallest and largest signal the transducer can measure.

- Resolution: The smallest change in input that the transducer can detect.

- Accuracy: How close the transducer’s output is to the true value.

Addressing Challenges in Sensitivity and Impedance

Piezo transducers are known for being sensitive, which is great for picking up subtle signals. However, this can also be a headache. In a busy industrial environment, with lots of machinery running, unwanted vibrations or electrical noise can interfere with the readings. This means you might get false positives or inaccurate measurements, which is the last thing you want when fine-tuning a spray pattern. It’s like trying to have a quiet conversation next to a rock concert.

Another thing to think about is impedance. Piezo transducers often have a high electrical impedance. This can make it tricky to connect them to other electronic components or measurement devices without losing signal strength or accuracy. You might need special signal conditioning circuits to properly read the output, which adds complexity and cost. It’s a bit like trying to pour water through a very narrow pipe – it slows things down and can get messy if you’re not careful.

Dealing with these sensitivity and impedance issues often involves careful system design. This might mean shielding the transducer from environmental noise, using specific amplification circuits, or selecting transducers made with materials that offer a better impedance match for your particular setup. It’s all about making sure the signal you want is clear and strong.

Ensuring Durability and Longevity in Harsh Environments

Industrial settings can be tough on equipment. Think about exposure to chemicals, extreme temperatures, high humidity, or constant vibration. These conditions can really wear down a piezo transducer over time. The materials themselves can degrade, becoming brittle or losing their piezoelectric properties. This means a transducer that works perfectly today might start failing in a few months or a year, leading to unexpected downtime and costly repairs.

To combat this, piezo manufacturers often use protective coatings or encapsulate the transducers. This helps shield them from corrosive substances and moisture. Selecting the right material for the job is also key; some piezoelectric ceramics are more robust than others. For applications involving spray nozzles, you’d want to look at transducers designed to withstand the specific chemicals being sprayed and the operating temperatures. It’s a bit like choosing the right kind of paint for a boat – you need something that can handle being constantly wet and exposed to the elements. Regular inspection and maintenance, even for these robust components, can go a long way in preventing premature failure and keeping your operations running smoothly.

Wrapping It Up

So, we’ve looked at how piezo transducers are pretty neat little devices. They change pressure into electricity and back again, which is why they show up in so many different things. From helping doctors see inside us with ultrasound to making our phones buzz when we type, they’re quietly doing a lot. It’s clear these components are not just for today’s tech; they’re going to be a big part of what’s next, especially with new materials and ideas coming out all the time. It’s kind of amazing how something so small can have such a big impact on the technology we use every single day.

Frequently Asked Questions

What exactly is a piezo transducer?

Think of a piezo transducer as a tiny, clever device that can do two cool things: it can turn physical pressure or movement into an electrical signal, and it can also do the opposite, turning an electrical signal into physical movement or sound. It works because of special materials that react to pressure by creating electricity, or by changing shape when electricity is applied to them.

How do these special piezo materials work?

These materials, like certain crystals and ceramics, have a unique property. When you squeeze them, their tiny parts line up in a way that creates a small electrical charge. It’s like a mini-generator powered by pressure! On the flip side, if you send electricity through them, their shape changes slightly, which is useful for making vibrations or pushing things.

Where might I find piezo transducers in everyday life?

You’re probably using them more than you think! They’re in your smartphone for things like haptic feedback (those little vibrations when you type), in medical devices for ultrasound imaging to see inside your body, and even in some car sensors. They’re also used in things like lighters to create a spark and in buzzers or tiny speakers.

Are piezo transducers good for making images?

Yes, they are fantastic for imaging, especially with ultrasound! In medical machines, they send out sound waves and then listen for the echoes that bounce back from inside your body. By analyzing these echoes, the machine can create detailed pictures, helping doctors see what’s going on without needing to cut you open.

Can piezo transducers help with energy?

Absolutely! Because they can create electricity when squeezed, scientists are exploring ways to use them for ‘energy harvesting.’ Imagine shoes that generate power as you walk, or devices that capture energy from vibrations in a factory. This could help power small electronics without needing batteries, which is great for the environment.

Are there any downsides to using piezo transducers?

While they’re amazing, they do have a few challenges. Sometimes they can be a bit too sensitive and pick up unwanted noise. The materials can also wear out over a very long time, especially in tough conditions. Also, getting accurate readings from them can sometimes be tricky because of how they handle electrical signals, but engineers are constantly working to make them better and more reliable.