Understanding Piezoelectricity in PZT

At its heart, the magic of PZT discs comes down to the piezoelectric effect. It’s a fascinating phenomenon where certain materials generate an electric charge when subjected to mechanical stress, like being squeezed or stretched. Conversely, applying an electric field to these materials causes them to deform, expanding or contracting. PZT, which stands for Lead Zirconate Titanate, is a ceramic material that exhibits this effect very strongly, making it incredibly useful.

Think of it like this:

- Direct Effect: Mechanical Stress → Electrical Charge

- Inverse Effect: Electrical Field → Mechanical Strain

This ability to convert between mechanical and electrical energy is what makes PZT discs so versatile. The crystal structure within the PZT material is key; when it’s deformed, the internal positive and negative charges shift, creating a voltage difference. It’s a pretty neat trick that allows for a wide range of applications, from sensitive sensors to precise actuators.

The Crucial Role of Polarization

Now, PZT doesn’t just magically become piezoelectric. It needs a special treatment called polarization. This process is what gives the PZT its directional properties. It involves heating the ceramic material and then applying a strong electric field. This field aligns the tiny magnetic-like domains within the PZT’s crystal structure. Once cooled down with the field still applied, these domains remain aligned, and the material becomes permanently piezoelectric.

Without proper polarization, a PZT ceramic is essentially inert, lacking the ability to convert mechanical energy to electrical signals or vice versa. This alignment is what imbues the material with its unique electromechanical coupling capabilities.

This polarization step is super important. If you heat the PZT too much or apply an electric field incorrectly, you can mess up this alignment, and the material will lose its piezoelectric properties. It’s like trying to reset a compass – you need to be careful with the magnetic fields involved. The strength and direction of this polarization directly influence how sensitive and powerful the PZT disc will be in its intended application. For instance, in applications requiring precise movement, like in some industrial spray nozzle adjustments, the polarization dictates the actuator’s response.

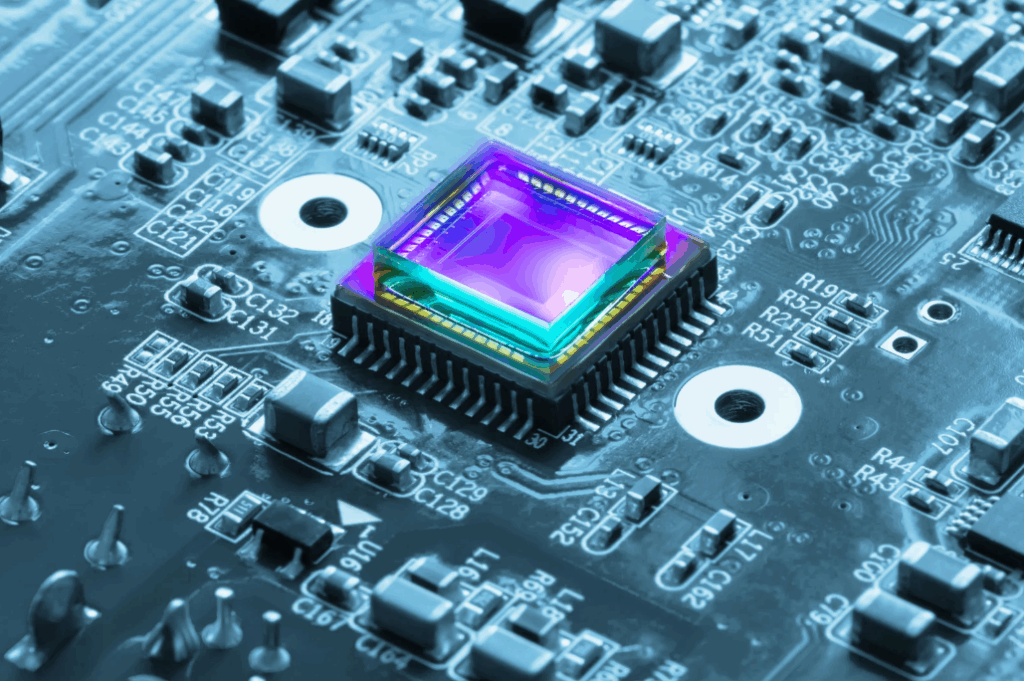

PZT Disc – From Ceramic to Transducer

So, how does this all come together? A PZT disc starts as a mixture of powders – lead, zirconium, and titanium oxides. These are processed, heated to form a solid ceramic, and then shaped into a disc. The critical step is the polarization, as we just discussed. Once polarized, the PZT disc is ready to be used as a transducer, a device that converts one form of energy to another.

Here’s a look at some key properties that define a PZT disc’s performance:

| Property | Typical Value | Importance |

| Piezoelectric d33 | 200-600 pC/N | Sensitivity in sensors, force in actuators |

| Curie Temperature | 200-350 °C | Maximum operating temperature |

| Dielectric Constant | 500-4000 | Energy storage, impedance matching |

| Density | ~7.5 g/cm³ | Weight and acoustic impedance |

These characteristics mean a PZT disc can be used to detect tiny vibrations, generate precise ultrasonic waves, or create controlled mechanical movements. It’s this ability to act as both a sensor and an actuator that makes the PZT disc such a valuable component in modern technology, from delicate scientific instruments to robust industrial equipment.

PZT Discs in Precision Actuation and Micro-Positioning

When you need to move things with really fine control, PZT discs are a go-to technology. They take an electrical signal and turn it into a tiny, precise mechanical movement. This is super handy for all sorts of jobs where even a microscopic shift matters. It’s all about the inverse piezoelectric effect – apply a voltage, and the PZT material expands or contracts just a little bit. The amount it moves is directly related to the voltage you apply, which means you can control it with a lot of accuracy.

Generating Highly Accurate Mechanical Motion

Think about needing to position something down to the nanometer level. That’s where PZT actuators really shine. Unlike traditional mechanical systems that can be clunky and imprecise at these scales, PZT discs offer a smooth, controlled motion. The displacement is proportional to the voltage, and you can adjust that voltage with high resolution. This makes them ideal for tasks requiring extreme precision, like aligning optical components or manipulating tiny samples.

Applications in Semiconductor Manufacturing

In the world of making computer chips, precision is everything. PZT discs are used in machines that need to place components or move wafers with incredible accuracy. For example, in photolithography, PZT actuators help position the masks and wafers precisely for etching circuits. They’re also used in automated inspection systems that scan for defects, where tiny, repeatable movements are key to covering the entire surface without missing anything. The speed and accuracy of PZT systems help keep production lines moving efficiently.

Enabling Nanometer-Scale Control

Achieving control at the nanometer scale is a big deal. PZT discs make this possible because their deformation is so small and so directly tied to the applied voltage. This allows for:

- Fine adjustments: Making tiny corrections to position or alignment.

- High repeatability: Returning to the exact same position every time.

- Fast response: Reacting quickly to control signals.

The ability to generate motion that is both incredibly precise and highly repeatable is what sets PZT actuators apart for demanding micro-positioning tasks. This level of control is hard to match with other technologies.

These capabilities are vital in fields like microscopy, where sample stages need to move smoothly under the lens, and in advanced manufacturing processes where components must be assembled with sub-micron tolerances. The compact size of PZT discs also means they can be integrated into tight spaces within complex machinery.

PZT Discs for Advanced Sensing and Measurement

PZT discs are really handy when you need to sense things accurately. They work by turning physical stuff, like vibrations or pressure, into electrical signals. This makes them super useful for all sorts of sensors where you need to pick up on small changes. Think about it – a tiny bit of pressure can create a measurable electrical output. It’s pretty neat how they can translate the physical world into something we can read.

Detecting Subtle Vibrations and Shocks

PZT discs are great at picking up on even the smallest shakes and bumps. Because they react quickly to mechanical stress, they can detect vibrations that might otherwise go unnoticed. This is a big deal for keeping an eye on the health of structures like bridges or buildings. By attaching PZT sensors, you can catch early signs of damage before they become serious problems. They’re also used to monitor machines, listening for unusual vibrations that could mean a part is about to fail. This kind of predictive maintenance can save a lot of headaches and money.

Here’s a quick look at how PZT sensors help with vibration analysis:

| Application | Vibration Type | PZT Sensor Output | Analysis Goal |

| Machine Condition Monitoring | High-frequency | Voltage signal | Detect bearing faults, imbalance, misalignment |

| Structural Health Monitoring | Low-frequency | Voltage signal | Detect cracks, corrosion, structural weakness |

| Seismic Monitoring | Very low frequency | Voltage signal | Measure earthquake magnitude and location |

Using PZT tech like this means you can spot potential issues early on, which is always a good thing.

Pressure and Force Measurement Capabilities

Need to measure how much pressure or force is being applied? PZT discs can handle that too. When you push on a PZT disc, it generates an electrical charge that’s directly related to the force applied. This makes them perfect for high-precision scales where accuracy is key. They’re also used in things like tire pressure monitoring systems in cars, giving you real-time readings. In industrial settings, they can keep tabs on pressure in pipelines or hydraulic systems, helping to prevent problems.

The sensitivity of PZT sensors to even minor pressure variations makes them suitable for applications where precise measurements are critical for safety and performance, such as in aerospace components.

Acoustic Sensing for Diverse Environments

PZT discs are also quite good at picking up sound waves. They’re used in microphones and even in underwater sensors, called hydrophones. When sound waves hit the disc, it vibrates, and that vibration creates an electrical signal. You can even adjust the size and shape of the disc to make it more sensitive to specific sound frequencies. This is really useful in applications like sonar, where you need to detect particular sounds from far away. Plus, PZT sensors can be made quite small, which is great for devices that need to be compact.

PZT Discs in Medical and Healthcare Innovations

PZT discs have really made a splash in the medical field, and it’s easy to see why. Their ability to convert electrical energy into mechanical motion, and vice versa, opens up a ton of possibilities for both diagnostics and treatment. From getting a clearer picture inside the body to delivering drugs more effectively, PZT discs are changing the game.

Enhancing Diagnostic Imaging with Ultrasound

Okay, so everyone’s probably heard of ultrasound, right? Well, PZT discs are at the heart of it. They generate the sound waves that bounce off tissues and create those images we see. The cool thing is, by tweaking the frequency and intensity of the waves, doctors can get different kinds of information. For example:

- High-frequency ultrasound gives really detailed images of shallow tissues.

- Lower frequencies can penetrate deeper, which is great for looking at organs.

- Doppler ultrasound uses the shift in frequency to measure blood flow.

Ultrasound is non-invasive and doesn’t use ionizing radiation, making it a safe and versatile tool for everything from prenatal checkups to diagnosing heart conditions. The precision offered by PZT medical applications is a big reason why it’s so widely used. These piezoelectric sensors are essential for high-resolution imaging.

Precision in Drug Delivery Systems

Getting drugs to the right place in the body, at the right time, is a huge challenge. PZT discs are being explored as a way to improve drug delivery. Here’s how:

- Nebulizers: PZT atomizers are widely used in the medical field. They are essential in devices like nebulizers, which help patients inhale medication in the form of a mist.

- Micro-pumps: Tiny PZT-driven pumps can deliver precise doses of medication directly to a specific area.

- Sonoporation: Ultrasound can temporarily disrupt cell membranes, allowing drugs to enter more easily.

These techniques could make treatments more effective and reduce side effects. It’s an exciting area with a lot of potential for future development. The use of piezoelectric tubes in drug delivery is an area of active research.

Potential in Therapeutic Applications

It’s not just about seeing what’s going on inside; PZT discs can also be used to do things. High-intensity focused ultrasound (HIFU) is one example. It’s like using a magnifying glass to focus sunlight, but with sound waves. This focused energy can be used to:

- Ablate tumors without surgery.

- Break up kidney stones.

- Stimulate tissue regeneration.

Another area is physiotherapy, where lower-intensity ultrasound can help with pain relief and healing. It’s pretty amazing how sound waves can be used to treat such a wide range of conditions.

Industrial and Commercial Applications of PZT Discs

PZT discs are more than just components for fancy gadgets; they’re actually pretty common in everyday industrial and commercial uses. Their knack for changing electrical energy into physical movement, and the other way around, makes them handy for all sorts of tasks. Let’s check out a few places you might find them.

Reliable Ignition Systems for Gas Appliances

Ever used a gas grill lighter or a gas stove without a pilot light? Chances are, a PZT disc was involved. When you push down on the igniter, you’re actually squeezing a PZT element. This quick mechanical action creates a high-voltage spark that ignites the gas. It’s a simple, reliable way to get a flame without needing batteries or complex electronics. You’ll find these in:

- BBQ igniters

- Gas range ignitions

- Propane torch starters

This makes them a go-to for applications where a consistent spark is needed, like in many industrial burners or even some older types of welding equipment.

Sound Generation and Transduction Technologies

PZT discs are fantastic at making and detecting sound. They’re used in a wide range of audio devices. Think about it: they can vibrate to create sound waves, like in small speakers or buzzers. On the flip side, sound waves hitting a PZT disc can make it vibrate and generate an electrical signal, which is how microphones and acoustic sensors work. They’re also key in ultrasonic cleaning devices, where high-frequency vibrations are used to clean delicate parts without harsh chemicals. For tasks requiring precise fluid handling, like in some types of inkjet printers or medical nebulizers, PZT actuators can precisely control the ejection of tiny droplets. This ability to generate fine mists is also useful in applications needing controlled atomization, such as specialized humidifiers or fuel injection systems. The frequency and intensity of the PZT’s vibration can be adjusted to control the droplet size, making them quite versatile for fluid control. For example, a durable brass flat nozzle with a 1/4 inch inlet, designed for consistent and uniform spray patterns, might work alongside PZT technology in certain atomization systems [5e8b].

Non-Destructive Testing for Material Integrity

This is where PZT discs really show their worth. Non-destructive testing (NDT) is all about checking materials for flaws like cracks or voids without damaging the item itself. PZT discs are used to send ultrasonic waves into a material. By listening to how these waves bounce back, technicians can spot hidden defects. This is super important for:

- Checking welds on pipelines and pressure vessels.

- Inspecting critical aircraft components for fatigue.

- Assessing the condition of concrete structures.

The ability of PZT discs to generate and detect ultrasonic frequencies makes them invaluable for quality control and safety inspections across many industries. They allow for early detection of problems, which can prevent failures and save significant costs.

Here’s a quick look at how PZT sensors are used in NDT:

| Application | Wave Type | PZT Function | Defect Detection |

| Weld Inspection | Ultrasonic | Transmitter/Receiver | Cracks, lack of fusion |

| Material Flaw Detection | Ultrasonic | Transmitter/Receiver | Voids, inclusions, delamination |

| Thickness Measurement | Ultrasonic | Transmitter/Receiver | Wall thinning |

Emerging Trends and Future Directions for PZT Discs

The world of PZT discs isn’t standing still. Researchers and engineers are constantly pushing the limits of what these components can do. It feels like every year there’s something new, making them even more useful across different industries. Let’s look at what’s coming up.

Development of Lead-Free PZT Alternatives

One of the biggest conversations happening right now is about lead. Traditional PZT materials have lead, and that’s becoming a problem for environmental and health reasons. So, a lot of work is going into finding materials that work just as well but don’t have lead. Scientists are trying out different combinations, like bismuth sodium titanate (BNT) and potassium sodium niobate (KNN). The goal is to get that same piezoelectric punch without the environmental baggage. This is a pretty big deal, especially as regulations get tighter.

Miniaturization and Integration with MEMS

Everything seems to be getting smaller, and PZT discs are no exception. The trend is towards making these discs thinner and smaller so they can be easily built into tiny devices. Think about integrating them into micro-systems, like tiny sensors or even medical implants. This involves using advanced manufacturing techniques to get high performance from really small components. It’s opening up new possibilities for where we can use piezoelectric technology.

Smart Materials and Adaptive Systems

Imagine materials that can sense what’s going on around them and react. That’s the idea behind smart materials, and PZT discs are a key part of that. By combining PZT discs with sensors and control systems, we can create systems that adjust themselves on the fly. For instance, a structure could use PZT actuators to reduce vibrations or change its shape when it feels a force. This could be huge for things like airplanes, cars, and buildings. The future is looking pretty adaptive.

The ongoing research into PZT discs is focused on making them more integrated, more sustainable, and more responsive. As new applications are discovered and technology improves, PZT discs will likely become even more important in many different fields.

Challenges and Considerations in PZT Disc Implementation

Ensuring Durability Under Stressful Conditions

PZT discs are pretty tough, but they aren’t indestructible. Over time, especially when they’re constantly being pushed, pulled, or exposed to high heat or strong electrical fields, their performance can start to drop. This means they might not be as sensitive or generate as much force as they used to. A few things can really wear them down:

- Mechanical stress: This includes being squeezed, stretched, or twisted.

- Electrical stress: Running them with high voltages or constantly switching the current.

- Temperature changes: Big swings in temperature can cause issues.

- Environmental factors: Things like moisture or corrosive substances can also take a toll.

It’s really important to think about where and how these discs will be used when you’re picking them out and designing your system. Sometimes, just using the right mounting methods or adding a protective coating can make a big difference in how long they last and how well they keep working.

Navigating Design and Fabrication Complexities

Putting PZT discs into a device isn’t always straightforward. Because they link electrical and mechanical actions, you have to be careful about things like matching their electrical resistance, figuring out their natural vibration points, and how they’ll connect mechanically. Making them can also be a bit of a headache, especially if you need very specific shapes or super precise measurements.

Some common design and making issues include:

- Getting the exact vibration frequencies you need.

- Reducing unwanted electrical interference.

- Making sure the material is polarized evenly.

- Attaching the PZT to other parts without putting extra strain on it.

To get around these problems, engineers often use computer simulations to fine-tune their designs before making anything. Having good tools for precise cutting and bonding is also key to making sure everything works reliably. Picking the right supplier for your PZT material is also a big step in getting good results.

Addressing Environmental Impact and Sustainability

Here’s a big one: many standard PZT materials contain lead, which isn’t great for the environment or our health. This is why there’s a lot of work going into finding alternatives that don’t use lead. While these new lead-free options are showing promise, they sometimes don’t perform quite as well as the old lead-based ones, or they have other trade-offs. We also need to think about:

- The lead content in older PZT types.

- How much energy is used to make them.

- What happens to PZT parts when they’re thrown away or recycled.

Researchers are looking into different materials, like those based on bismuth or niobium, to see if they can match the performance of lead-based PZT without the environmental baggage. It’s a tough challenge, but an important one for the future.

The Enduring Impact of PZT Discs

So, we’ve seen how these little PZT discs are really everywhere, doing all sorts of jobs. From making precise movements in machines to helping us see inside our bodies with ultrasound, they’re pretty amazing. They can turn electricity into motion and back again, which is why they’re so useful in sensors, speakers, and even gas lighters. While there are definitely some tricky parts to using them, like making sure they last and finding eco-friendly options, the work being done now is pretty exciting. It feels like PZT discs are just getting started, and we’ll probably see them in even more cool tech down the road. They’re a quiet but important part of the modern world.

Frequently Asked Questions

What exactly is a PZT disc and how does it work?

A PZT disc is a special kind of ceramic material. It has a cool trick: when you apply electricity to it, it slightly changes shape. And if you squeeze or stretch it, it creates a small electrical charge. This special ability makes it useful in lots of different gadgets and machines.

Where are PZT discs commonly used today?

You can find PZT discs in many everyday items! They help make sounds in speakers and pick up sounds in microphones. They’re also used in medical tools like ultrasound machines to see inside the body, and even in gas lighters to create a spark for ignition.

What are some difficulties in using PZT discs?

One of the main challenges is making sure PZT discs last a long time, especially when they are used a lot or in tough environments. Also, making them super small and fitting them into new, tiny devices can be quite tricky to design and build.

Are there new kinds of PZT discs being developed?

Yes, absolutely! Scientists are working hard to create new PZT materials that don’t contain lead, which is better for the environment. They are also trying to make these discs even smaller and smarter so they can perform more advanced tasks in future technologies.

How do PZT discs help in medical tools?

In the medical world, PZT discs are super important for ultrasound machines, which help doctors see images of things inside the body, like a developing baby or internal organs. They are also used in some treatments and are being explored for new ways to deliver medicine precisely where it’s needed.

How are PZT discs used to detect things?

PZT discs are excellent at sensing very small changes, such as pressure or vibrations. This makes them perfect for devices like earthquake detectors, systems that monitor the shaking of buildings, or even for creating touch-sensitive screens.