PVDF Piezoelectric Film Sensors

At Piezo Direct, we don’t just specialize in PZT ceramics—we are also a manufacturer of PVDF piezoelectric film sensors, designed for applications where flexibility, lightweight design, and durability are critical. Unlike rigid ceramic discs, PVDF films can conform to curved or moving surfaces, making them ideal for wearables, medical devices, energy harvesting, and advanced industrial monitoring.

PVDF films are produced by casting or extruding thin sheets of polyvinylidene fluoride. These sheets are metallized with electrodes and then undergo poling, a process that aligns molecular dipoles to create permanent piezoelectric properties. Advanced manufacturing methods, such as screen printing and electrospinning nanofibers, allow for precise control over thickness, sensitivity, and performance. Composite doping with materials like graphene or ZnO further improves responsiveness and durability.

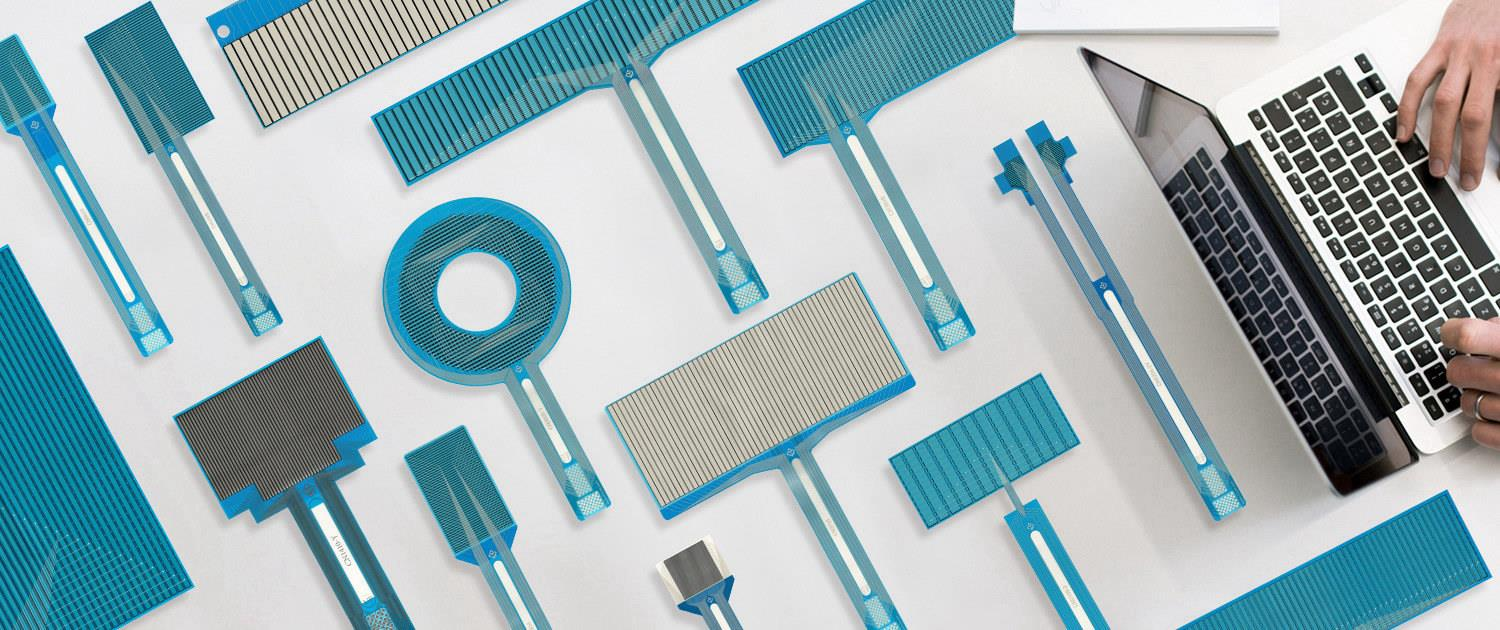

Because Piezo Direct controls the full manufacturing process, we deliver both standard and custom PVDF sensors. Our engineers work with you on material selection, electrode patterning, and integration strategies to ensure each film sensor is optimized for its operating environment.

PVDF Film Sensors

PVDF piezo film is a flexible polymer with strong piezoelectric properties. Compared to ceramic-based alternatives (like PZT), PVDF offers:

Lightweight, thin form factor, and mechanical flexibility for curved or wearable surfaces.

High piezoelectric charge constant—up to 10x higher than quartz—for dynamic signal detection.

Wide frequency responsiveness and low acoustic impedance.

Excellent chemical resistance, fatigue durability, and thermal stability.

Lead-free, eco-friendly composition, making it safer for medical and consumer applications.

These properties make PVDF sensors well-suited for applications that require dynamic pressure and vibration sensing, portable or wearable platforms, and low-power operation.

Piezo Direct as Your Partner

As industries continue to demand lead-free, sustainable alternatives to ceramics, PVDF film sensors are shaping the future of sensing technology. From aerospace and industrial monitoring to wearables and medical devices, PVDF delivers the flexibility, sensitivity, and eco-friendly design modern applications require.

At Piezo Direct, we combine expertise in PZT ceramics with innovation in PVDF polymers, offering customers the best of both worlds. Whether you need high-output piezo discs or versatile thin-film sensors, we manufacture application-specific components built for performance, reliability, and precision.

- Mechanics

- Applications

- Materials

- Custom

PVDF Film Sensor

Mechanics

Like other piezoelectric materials, PVDF films rely on the direct piezoelectric effect. When mechanical stress (such as bending, vibration, or pressure) is applied to the polarized film:

The molecular dipoles shift, generating a surface charge.

This charge translates into an output voltage signal.

The result is a sensitive, flexible sensor capable of detecting even subtle changes in force or motion.

PVDF’s strength lies in dynamic measurements rather than static pressures, making it particularly effective in acoustic sensing, vibration analysis, and energy harvesting applications.

Applications of PVDF Film Sensors

Medical & Wearables

Ultrasound and diagnostic imaging devices.

Drug delivery systems and nebulizers using PVDF atomizers.

Wearable sensors for motion, pressure, or gesture recognition.

Aerospace & Industrial

Wall-pressure sensing arrays in aerodynamics and wind-tunnel research.

Structural health monitoring of bridges, pipelines, or aircraft components.

Vibration and impact detection in rotating machinery.

Energy Harvesting & IoT

Piezoelectric nanogenerators (PENGs) to capture ambient vibration or motion.

Flexible, self-powered sensors for wireless IoT networks.

Lightweight energy harvesting patches for portable electronics.

Consumer Electronics

Thin, flexible microphones and acoustic sensors.

Haptic feedback for touch interfaces.

Compact sound generation devices.

PVDF vs. Traditional PZT Materials

| Attribute | PVDF Film | Ceramic (e.g., PZT) |

|---|---|---|

| Flexibility | Excellent—thin, bendable | Rigid, brittle |

| Sensitivity | Moderate but effective | Very high |

| Weight | Lightweight, portable | Heavier |

| Biocompatibility | High—ideal for wearables/medical | Lower—often lead-based |

| Environmental Safety | Lead-free, eco-friendly | Contains lead (toxic) |

Custom PVDF Sensors

Piezo Direct’s PVDF film sensors can be customized by shape, thickness, electrode patterning, and performance level. Whether you need an ultra-thin film for wearable health devices, patterned arrays for industrial testing, or low-power harvesting sensors for IoT, we can design a tailored solution.

Not sure which configuration you need? Contact Piezo Direct—our engineering team will collaborate with you to select the right material and build a PVDF sensor that meets your exact requirements.