Piezo Direct stands at the forefront of innovation, specializing in the development and production of cutting-edge piezo atomizers. Our commitment lies in harnessing the remarkable properties of piezoelectric technology to create ultrasonic marvels capable of vibrating and atomizing liquids.

Piezo Direct can provide three types of atomizers, namely single-chip piezo mesh atomizer, ultrasonic atomizer, and focused ultrasonic atomizer. Each type has its own characteristics and advantages, which will be introduced separately below.

Single-Chip Piezo Mesh Atomizer

At the core of our technology lies the single-chip piezo mesh atomizer, a testament to engineering and efficiency. Designed with a focus on versatility, these atomizers cater to a broad spectrum of applications, making them the ideal choice for industries ranging from healthcare to agriculture.

Key Features of our Single-Chip Piezo Mesh Atomizer

- Metal Mesh Mastery: Our piezo atomizers leverage the power of meticulously crafted metal mesh technology. The intricate design utilizes the sides of the mesh to achieve exceptional liquid atomization, ensuring optimal performance.

- Fine-tuned Efficiency: Optimal Driving Voltage (50 to 80Vp-p): Engineered for peak efficiency, our piezo atomizers operate within an optimal driving voltage range of 50 to 80Vp-p. This meticulous calibration guarantees flawless operation, maximizing the potential of your application.

- Frequency Finesse: Adaptable Signal Frequency: Our piezo atomizers demonstrate remarkable adaptability, seamlessly working with a sine signal frequency tailored to the specific requirements of each application. This ensures perfect harmony between the driving force and the atomizer, leading to superior results.

- Environmental Adaptability: Built to Withstand: These robust piezo atomizers are designed to function flawlessly within a temperature range of -10 to 40°C and an environment with humidity levels of up to 75%. This adaptability allows for their integration into diverse environments without compromising performance.

Ultrasonic Atomizer

The ultrasonic atomizer is a highly efficient atomizer that combines piezoelectric technology and material innovation. Its core advantages stem from its unique structural design and material properties. This atomizer uses piezoelectric ceramic as the substrate, and its surface is covered with a glass glaze coating fired at high temperature. This composite structure not only retains the high-frequency vibration characteristics of the piezoelectric material but also achieves excellent acid, alkali and moisture resistance through the glass glaze layer. It can adapt to various liquid environments such as water, essential oils, and medicinal liquids, effectively solving the problem of easy corrosion of traditional nickel-plated or titanium-plated atomizers.

Key Features of our Ultrasonic Atomizer

- Atomization efficiency: Our ultrasonic atomizer features outstanding atomization efficiency and a large flow rate. Combined with high-frequency vibration, it can convert liquid into delicate micron-sized particles, enhancing the atomization absorption effect.

- high energy conversion efficiency: Our ultrasonic atomizer has high energy conversion efficiency. The impedance of the product is as low as below 2Ω, with small dielectric loss. It generates little heat during operation, combining energy – saving and stability.

- An extremely long service life: The service life of our ultrasonic atomizers far exceeds that of traditional products. The cumulative working time can reach over 8000 hours, and it has excellent long – term stability.

- The surface is smooth and flat: After high – temperature treatment, the glaze surface has high microscopic flatness. It combines self – cleaning function and antibacterial properties, reducing the adhesion of scale and the growth of bacteria, and lowering the maintenance frequency.

Focused Ultrasonic Atomizer

The focused ultrasonic atomizer achieves a dual breakthrough in energy utilization and atomization efficiency through an innovative structural design. Compared with traditional flat atomizer, its core advantage lies in the precise concentration of vibration energy through the optimization of physical structure, forming a highly efficient atomization field. It specifically adopts a spherical piezoelectric ceramic substrate; the spherical curvature design focuses the ultrasonic vibration energy on the atomization area. It can be driven with only relatively low voltage and power, reducing energy consumption by more than 60% compared with traditional products, and increasing the atomization volume by 30% under the same conditions. From the physical innovation of energy focusing to the precise adaptation to multiple scenarios, this type of atomizer redefines the efficiency standard of atomization technology.

Key Features of our Focused Ultrasonic Atomizer

- Efficient Energy Concentration with Significantly Reduced Loss: A spherical piezoelectric ceramic substrate is adopted, and the ultrasonic vibration energy is accurately focused on the atomization area through the optimization of physical structure, avoiding the energy dispersion problem of traditional flat atomizers. It can be driven with a minimum voltage of only 5V and a current of 1A. Compared with traditional products, its energy consumption is reduced by more than 60%, and the atomization efficiency is increased by 40% under the same power, realizing “low consumption and high energy” operation.

- Controllable Atomization Precision and Excellent Particle Uniformity: The median particle size can be accurately adjusted according to scenarios. The particle uniformity is improved by more than 30% compared with traditional flat atomizers, which effectively solves the unstable atomization effect caused by edge water accumulation and uneven particle size.

- Low Consumption, Long Battery Life and More Outstanding Portability: Relying on the low-power design of core components, the battery life of the portable focused atomizer is greatly improved. It is especially suitable for mobile scenarios such as home medical care and outdoor aromatherapy, balancing performance and ease of use.

- Support for Customized Design in Multiple Fields: According to different applications, focusing points and power requirements, customized design and production are provided.

Specialization in Small Particle Generation

Piezo Direct specializes in producing atomizers that generate exceptionally small particles, making them ideal for applications like nebulizers. This is because only particles smaller than 5 micrometers can effectively reach the lungs. To maximize nebulizer effectiveness, it’s crucial to produce as many particles as possible within this size range.

Our technology allows for the creation of mesh holes as small as 2.5 microns, the smallest achievable size with current mesh-based atomizer technologies. Since particle size (or Mass Median Aerodynamic Diameter, MMAD) directly correlates with mesh hole size, our atomizers are particularly well-suited for nebulizer applications.

Beyond Nebulization

Piezo atomizers have applications in a multitude of industries, including:

- Medical and Healthcare: Targeted respiratory treatments become a reality with the integration of our atomizers into inhalation therapy devices.

- Agricultural Revolution: Cultivate efficiency in crop spraying systems. Our atomizers ensure the meticulous distribution of pesticides, fertilizers, and growth regulators, empowering agricultural advancements.

- Personal Care and Cosmetics: Indulge in a refreshing experience with facial misters and fragrance diffusers powered by Piezo Direct’s atomizers.

Piezo Atomizers – The Future of Liquid Delivery

Piezo Direct’s piezo atomizers represent a transformative leap forward in liquid atomization technology. Their exceptional versatility, coupled with a commitment to meticulous particle size control, makes them an indispensable asset for a wide range of industries. As we continuously strive for innovation, Piezo Direct remains dedicated to pushing the boundaries of what’s possible, paving the way for a future filled with even more groundbreaking applications of piezo atomization technology.

Piezo Direct: Your Source for High-Performance Piezo Atomizers

Piezo Direct is your trusted partner for designing and manufacturing world-class piezo atomizers. Our expertise in piezoelectric technology allows us to deliver atomization solutions that surpass industry benchmarks in performance, reliability, and customization capabilities.

Uncompromising Quality in Piezo Atomizer Manufacturing

Our commitment to quality begins with meticulously sourcing premium piezoelectric materials. These materials, renowned for their superior piezoelectric properties and long-term durability, form the backbone of our atomizers’ exceptional performance.

Engineering for Unmatched Atomization

We employ state-of-the-art manufacturing processes to transform piezoelectric materials into atomizers.

Rigorous Testing Ensures Reliability

Every piezo atomizer leaving our facility has undergone extensive testing and validation. We assess atomization efficiency, droplet size distribution, flow rates, and overall performance, ensuring our products consistently exceed your expectations.

Customization: Tailored Solutions for Your Application

We understand the unique needs of our clients across diverse industries. Piezo Direct offers bespoke piezo atomizer solutions, including customized designs, flow rate, particle size, spray effect, and other aspects, to address your specific application requirements.

Eliminating Toxic Lead Without Compromising Performance

Piezo Direct is one of the first manufacturers in the world to develop lead-free piezo atomizers, setting a new standard for safety and environmental responsibility in piezoelectric technology. While lead is widely recognized as a toxic element that has been banned or heavily restricted in most consumer and industrial products, traditional piezoelectric components still contain lead-based materials. Exposure to lead, even in small amounts, can cause severe health issues, including neurological damage, developmental disorders, and organ failure. In industries where safety is paramount—such as medical devices—minimizing exposure to hazardous substances is critical. Piezo Direct’s cutting-edge technology eliminates the need for lead in piezo atomizers, offering a safer alternative without compromising performance.

Advancing Eco-Friendly Piezoelectric Solutions

This breakthrough is especially significant for medical applications that rely on piezo atomizers for aerosol delivery, including nebulizers and drug delivery systems. Inhaling medication through atomization ensures effective treatment, but traditional lead-containing piezo components pose potential contamination risks over time. By pioneering lead-free piezo atomizer technology, Piezo Direct is providing healthcare manufacturers with a safer, RoHS-compliant solution that meets the strictest medical safety regulations. As the demand for eco-friendly, non-toxic piezoelectric products grows, Piezo Direct remains at the forefront of innovation, delivering superior, lead-free solutions for the future of medical and commercial applications.

Standard Products Offering

In addition to our custom atomizers, Piezo Direct now offers standard off-the-shelf piezo atomizers for immediate integration into your applications. These standard products provide the same high-quality performance and engineering as our custom solutions, making them ideal for projects with quicker timelines or more general requirements. Our standard piezo atomizers are available in a variety of configurations, ensuring you can find the right solution to meet your atomization needs without the need for customization.

Benefits of Our Standard Products:

- Ready-to-ship for faster deployment

- Industry-leading quality and reliability

- Available in mesh-based and disc-based designs

- Ideal for common applications such as humidification, medical nebulizers, and consumer products

Industries We Serve:

- Medical: Inhalers, nebulizers, medical coatings

- Industrial: Humidification, cooling, dust suppression

- Agriculture: Pesticide and nutrient delivery

- Consumer Goods: Humidifiers, aroma diffusers, skincare

- And more!

Why Partner with Piezo Direct?

- Uncompromising quality control

- Customization expertise

- Standard product availability for faster solutions

- Dedication to client success

- Leading innovator in atomization technology

Whether you need a fully customized piezo atomizer or a high-quality standard product, Piezo Direct has the solutions to meet your needs. Explore our standard product offerings or contact us to discuss your custom atomization requirements.

-

Features

-

Applications

-

Specifications

Understanding Piezo Atomizers: Features and Benefits for Optimal Atomization

Piezoelectric atomizers are versatile tools that leverage the power of piezoelectric materials to convert liquids into fine mists or aerosols. Their unique features make them ideal for numerous applications. Here’s a breakdown of their advantages:

Key Features of Piezo Atomizers

- Highly Efficient Atomization: Piezo atomizers transform liquids into fine droplets with exceptional efficiency. This ensures optimal coverage and distribution of the atomized substances, resulting in effective and consistent results.

- Uniform Spray Patterns: Achieve reliable results with piezo atomizers, which deliver remarkably even and consistent spray effects. This is critical for applications like:

- Agricultural Crop Spraying

- Medical nebulizers

- Rapid Atomization: When time is of the essence, piezo atomizers excel due to their high-speed liquid-to-aerosol conversion. They’re ideal for:

- Medical inhalation devices

- Fast-paced industrial processes

- Energy Efficiency: Piezo atomizers operate with minimal power consumption, reducing your operational costs and increasing sustainability compared to alternative atomization methods.

- Versatility with Diverse Liquids: These atomizers effectively handle a wide range of liquids, including:

- Water-based solutions

- Oil based

- Solvent based

- Suspensions (The suspended particles must be smaller than the hole size)

- Specialized fluids (medical, industrial, etc.)

- Compact and Lightweight: Piezo atomizers integrate seamlessly into systems, thanks to their small size and minimal weight. This is a major advantage for devices where space and weight are primary concerns.

- Work quietly: This quiet feature allows the atomizer to seamlessly adapt to various sensitive scenarios:

- When used in the bedroom at night, it does not disturb deep sleep.

- When placed in the office, it does not interfere with work communication or concentration.

- When used in the nursery room, the gentle atomization process will not startle infants and young children.

This enables the atomizer to naturally integrate into daily life in tranquility, not only meeting the demand for air humidification but also preserving the quiet and peaceful quality of the environment.

- Fast Response for Control: Piezo atomizers allow for immediate on/off switching and rapid adjustments, enabling fine control over atomization processes.

Applications Across Industries

Piezo atomizers find use in a multitude of industries, including:

- Medical: Inhalers, nebulizers, humidifiers

- Industrial: process control

- Agriculture: Crop spraying, pest control, humidification

- Consumer Goods: Humidifiers, air purifiers, fragrance diffusers

Piezo Direct: Your Source for Advanced Piezo Atomizers

If you’re seeking efficiency and control in your atomization processes, Piezo Direct offers a wide selection of high-quality piezo atomizers. Our team can guide you to the perfect solution for your unique needs. Contact us today!

Applications of Piezo Atomizers: Versatility Across Industries

Piezo atomizers harness the power of piezoelectric transducers to create fine mists, making them valuable tools in diverse fields. Explore the extensive ways these atomizers are transforming industries:

Humidification and Air Purification

- Industrial humidification: Maintain optimal humidity levels in manufacturing facilities, storage areas, and other industrial settings to ensure product quality and process efficiency.

- Home humidifiers: Create a comfortable living environment by preventing dry air and its associated health issues.

- Air purifiers: Used in conjunction with air purification systems, piezo atomizers can disperse water-soluble cleaning agents or disinfectants for cleaner, healthier air.

Medical Applications

- Inhalers and nebulizers: Deliver medication in mist form directly to the lungs for the treatment of asthma, COPD, and other respiratory conditions.

Fragrance and Flavor Industries

- Aroma diffusers: Enhance ambiance and well-being by atomizing essential oils, creating a relaxing and pleasant atmosphere.

- Flavor atomizers: Innovate food and beverage preparation by delicately infusing flavors and aromas.

- Car fragrance: Provide a personalized scent experience within vehicles.

Industrial Applications

- Cooling systems: Atomized water provides energy-efficient cooling in industrial settings and greenhouses.

- Dust suppression: Control dust in construction and mining sites by atomizing water to bind airborne particles.

Additional Innovative Applications

- Skin care: Gently distribute skincare products or mists for hydration and refreshment.

- Disinfection: Effectively spread disinfectants for surface and space sanitization.

- Medical device coatings: Applied for evenly spread coatings on medical devices and implants.

- Agriculture: Facilitate controlled delivery of pesticides or nutrients in agricultural settings.

Single-Chip Piezo Mesh Atomizer

To ensure optimal integration of our single-chip piezo mesh atomizers, we provide a detailed breakdown of their technical specifications.

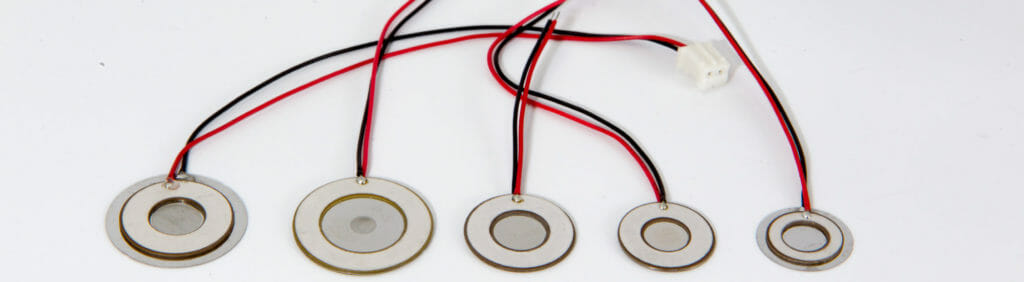

Diameter

The diameter of the atomizer mainly depends on the design of the product. Common sizes include 8mm, 10mm, 12mm, 13.8mm, 15mm, 16mm and 20mm. If there is no limitation on the size, we recommend using the product with a diameter of 16mm.

Resonant Frequency

The resonant frequency is related to the diameter of the atomizer. Their corresponding relationship is shown in the following table.

Diameter [mm] | Resonant Frequency [KHz] |

8 | 220 |

10 | 160 |

12 | 145 |

13.8 | 125 or 160 |

15 | 110 |

16 | 110 |

20 | 95, 105 or 111 |

*The above table is for reference only. The resonant frequency may have slight variations in different application scenarios.

Mass Median Aerodynamic Diameter(MMAD)

The MMDA mainly depends on the mesh hole size. According to different application requirements, we can achieve a range between 3 and 40 μm.

Atomization Quantity

The atomization quantity mainly depends on the mesh hole size and the number of holes. In addition, other factors such as the type of liquid used, whether it is direct contact with water or with a wick, and the output power of the driving board, etc., will also have an impact on the atomization quantity. According to different application requirements, we can achieve a range of 0.1 to 50 ml/min.

The following is a table of several typical corresponding relationships between the mesh hole size, the number of holes, the MMAD and the atomization quantity, which can be used as a reference for model selection.

Diameter | Mesh hole size | Number of holes | MMAD | atomization quantity |

8 | 2.5 | 600 | 4 | 0.3 |

6 | 1000 | 8 | 3 | |

10 | 300 | 12 | 3 | |

10 | 3.5 | 500 | 5 | 0.2 |

7 | 540 | 16 | 2 | |

8 | 600 | 22 | 3 | |

12 | 3 | 800 | 4 | 0.3 |

6 | 700 | 8 | 1.2 | |

13.8 | 5 | 600 | 7 | 0.5 |

9 | 300 | 25 | 4 | |

15 | 3 | 2600 | 4 | 0.5 |

16 | 2.5 | 2600 | 3.5 | 0.4 |

4 | 1200 | 7 | 0.6 | |

7 | 1000 | 16 | 3.5 | |

9 | 3000 | 30 | 12 | |

20 | 2.5 | 4000 | 3 | 0.6 |

5 | 2800 | 13 | 1.8 | |

13 | 900 | 20 | 10 |

*The experimental liquid is water, direct contact with water and using a standard driving board.

Understanding the Implications

These specifications offer valuable insights for engineers and integrators. For instance, the resonant frequency range dictates the type of driving signal required for operation, while understanding impedance and capacitance is crucial for designing suitable circuits. The atomization quantity, in conjunction with the particle size capabilities, provides an indication of the mist volume and fineness generated, which are key factors in applications like nebulizers.

Customization

We make custom piezo atomizers based on your specific requirements. Please answer the following questions and we will identify the type of piezo atomizer you need.

- atomization quantity. For example, 5ml / min

- Desired particle size (MMAD). For example, 5μm

- Diameter of the atomizer (8mm, 10mm, 12mm, 13.8mm, 15mm, 16mm and 20mm). If you don’t have any size limitations, we recommend 16mm atomizers.

- Ph level of the liquid.

- Viscosity of the liquid

- Whether a wick is used

- Whether a matching driving board is needed

Tips

- Compatible Liquids:

- Recommended: Tap water or drinking water.

- Not recommended: Distilled/deionized water.

- For special liquids (such as H2O2): PI film products can be selected. It is recommended to contact us for consultation.

- Liquids Temperature:

- Long-term operating temperature: < 40℃.

- Short-term maximum temperature: < 60℃.

- Overheating can cause depolarization of the piezo ring, leading to performance degradation or permanent damage.

- Recommended Power:

- Medical inhalation: Long-term ≤1.2W, voltage ≤80Vpp.

- Other applications: Long-term ≤1.5W, voltage ≤80Vpp.

- Short-term cleaning: Up to 1.8 – 2W

- Particles of Different Sizes (MMAD) Can Reach:

- <5μm: Reaches bronchioles and alveoli (suitable for asthma, COPD).

- 5–10μm: Deposits in the upper respiratory tract (throat, trachea).

- 10μm: Mostly intercepted by the nose or mouth.

- Accessories & Integration:

- Matching Driver Board: Can be provided (supports prototyping and mass production).

- Wick Usage Recommendations: Flow rate is only 40–50% of direct water contact.

- Silicone grommets: Available (12mm, 15mm requires customization).