Ultrasonic piezo transducers are vital in medical engineering, offering a range of applications that enhance patient care and diagnostic accuracy. These devices are compact, energy-efficient, and highly reliable, making them ideal for various medical uses.

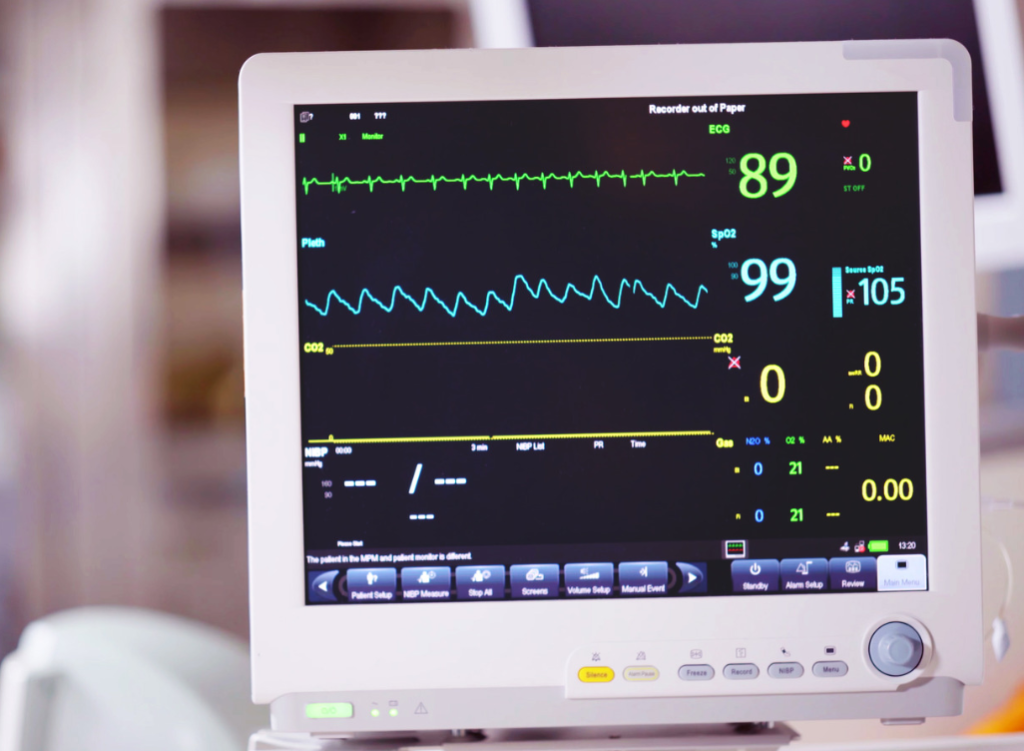

Patient Monitoring Systems

Ultrasonic piezo transducers play a crucial role in patient monitoring systems. They are used to measure vital signs such as heart rate and respiratory rate. These transducers measure temperature changes by observing resistance variations, which is useful in monitoring body and skin temperatures.

Ultrasonic Imaging

In the field of ultrasonic imaging, piezo transducers are indispensable. They help create detailed images of internal organs, tissues, and blood flow. This technology is essential for diagnosing conditions without invasive procedures.

Therapeutic Ultrasound

Therapeutic ultrasound uses piezo transducers to deliver targeted treatment. This method is effective in physical therapy, where it helps in reducing pain and promoting tissue healing. The precision of these transducers ensures that the treatment is both safe and effective.

The versatility of ultrasonic piezo transducers in medical engineering cannot be overstated. From monitoring vital signs to aiding in complex diagnostic procedures, these devices are integral to modern healthcare.

Role of Ultrasonic Piezo Transducers in Semiconductor Technology

Wafer Inspection

Ultrasonic piezo transducers are essential in wafer inspection processes. They help detect tiny defects and irregularities on semiconductor wafers, ensuring high-quality production. These transducers work by using high-frequency sound waves to scan the wafer surface, revealing any imperfections that might affect the final product.

Microfabrication Processes

In microfabrication, ultrasonic piezo transducers play a crucial role. They are used for precise etching and cleaning of semiconductor materials. This ensures that the microstructures are accurately formed and free from contaminants. The ability to control all critical manufacturing steps reduces the design cycles and time to market.

Quality Control

Quality control in semiconductor manufacturing heavily relies on ultrasonic piezo transducers. They are used to bond minute wires in semiconductor chips and to inspect the integrity of these bonds. This ensures that the final products meet the required standards and function correctly.

Ultrasonic piezo transducers are vital in maintaining the high standards required in semiconductor technology. Their ability to detect and correct defects ensures the reliability and performance of semiconductor devices.

Design Flexibility and Customization in Ultrasonic Piezo Transducers

Ultrasonic piezo transducers are used in many fields, from medical to semiconductor industries. Because there is no one-size-fits-all solution, manufacturers need to offer flexibility in materials, mechanical design, and the willingness to work with customers from various markets. This flexibility helps in reducing design cycles and time to market.

Ultrasonic Piezo Transducers in Industrial Applications

Ultrasonic piezo transducers are vital in many industrial applications due to their versatility and reliability. These devices are used in various fields, from flow measurement to structural health monitoring, providing accurate and efficient solutions.

Flow Measurement

Ultrasonic piezo transducers are commonly used in flow measurement systems. They help in determining the flow rate of liquids and gases in pipelines. These transducers are preferred because they are non-intrusive and can measure flow without coming into contact with the fluid.

Level Measurement

In level measurement, ultrasonic piezo transducers are used to detect the level of substances in tanks and silos. They provide precise readings, which are crucial for maintaining the correct levels of materials in industrial processes. The piezoceramic components in these transducers ensure high accuracy and durability.

Structural Health Monitoring

Structural health monitoring is another critical application of ultrasonic piezo transducers. They are used to detect cracks and other structural issues in buildings, bridges, and other infrastructure. This helps in preventing accidents and ensuring the safety of structures.

The ability to control all critical manufacturing steps reduces the design cycles and time to market, making ultrasonic piezo transducers an essential component in modern industrial applications.

Advancements in Piezoelectric Materials for Ultrasonic Transducers

The field of piezoelectric materials for ultrasonic transducers has seen significant progress. These advancements are crucial for improving the performance and reliability of various applications, from medical devices to industrial systems.

Piezoceramic Composites

Piezoceramic composites have become the dominant material for transducers due to their excellent piezoelectric properties and ease of manufacture. They can be shaped into various forms and operate at low voltage, making them highly versatile.

High-Frequency Applications

With ongoing advancements in materials, high-frequency applications are now more feasible. These materials allow for better resolution and more precise measurements, which are essential in fields like medical imaging and semiconductor technology.

Durability and Reliability

The selection of piezoelectric materials for ultrasonic transducers is critical for ensuring durability and reliability. Modern materials are designed to withstand harsh conditions, making them suitable for a wide range of environments.

The ongoing advancements in materials and technology are paving the way for more efficient and reliable ultrasonic transducers.

Integration of Ultrasonic Piezo Transducers in Nano and Biotechnology

Ultrasonic piezo transducers are making significant strides in the fields of nano and biotechnology. These tiny devices are capable of performing nano-scale measurements with incredible precision, which is crucial for advancements in these areas. They are also being used in various bio-sensing applications, providing accurate and reliable data for medical and research purposes.

Nano-Scale Measurements

Ultrasonic piezo transducers excel in measuring extremely small distances and changes at the nano level. This capability is essential for developing new technologies and materials in the nano and biotechnology sectors. Their ability to provide precise measurements helps in understanding and manipulating materials at the molecular level.

Bio-Sensing Applications

In the realm of bio-sensing, ultrasonic piezo transducers are invaluable. They are used in devices that monitor biological processes and detect various biological markers. This technology is crucial for early disease detection and monitoring, making healthcare more effective and efficient.

Lab-on-a-Chip Devices

Lab-on-a-chip devices, which integrate multiple laboratory functions on a single chip, benefit greatly from ultrasonic piezo transducers. These transducers enable the precise control and manipulation of fluids at a microscopic level, which is essential for the functionality of these devices. This integration enhances the efficiency and accuracy of lab-on-a-chip systems, paving the way for advanced diagnostic and research tools.

Challenges and Solutions in Ultrasonic Piezo Transducer Manufacturing

Manufacturing ultrasonic piezo transducers involves several challenges that need to be addressed to ensure high-quality products. Precision engineering is crucial to achieve the desired performance and reliability. This requires advanced design and micromanufacturing technologies to create components with exact specifications.

Precision Engineering

Precision engineering is essential for producing ultrasonic piezo transducers that meet strict performance standards. Manufacturers must use advanced tools and techniques to ensure each component is made to exact specifications. This includes maintaining tight tolerances and using high-quality materials.

Cost-Effective Production

Producing ultrasonic piezo transducers can be expensive due to the specialized materials and processes involved. To keep costs down, manufacturers need to find ways to streamline production without compromising quality. This might involve automating certain steps or finding more affordable materials that still meet performance requirements.

Quality Assurance

Ensuring the quality of ultrasonic piezo transducers is vital for their success in various applications. Manufacturers must implement rigorous testing and inspection processes to identify any defects or inconsistencies. This helps to maintain high standards and deliver reliable products to customers.

Finally, the challenges and opportunities of focused ultrasound transducers highlight the importance of continuous improvement in manufacturing processes.

Ultrasonic piezo transducers are incredibly versatile tools in modern engineering. They find applications in fields as varied as medical technology, semiconductor manufacturing, and chemical engineering. These devices can detect tiny changes and convert them into useful signals, making them essential for tasks like patient monitoring and industrial cleaning. The ability to customize materials and designs means they can be tailored to specific needs, ensuring they work effectively in different environments. As technology advances, the role of these transducers will only grow, helping to make processes more efficient and reliable.

Frequently Asked Questions

What are ultrasonic piezo transducers used for?

Ultrasonic piezo transducers are used in many fields like medical engineering, semiconductor technology, and industrial applications. They help in tasks like patient monitoring, wafer inspection, and flow measurement.

How do ultrasonic piezo transducers work?

These transducers convert electrical energy into mechanical energy and vice versa. They use piezoelectric materials to produce ultrasonic waves, which can then be used for various applications.

Why is flexibility important in designing ultrasonic piezo transducers?

Flexibility is key because different applications require different materials and designs. Custom solutions help meet the specific needs of diverse markets like medical and semiconductor industries.

What are some advancements in piezoelectric materials?

Recent advancements include the development of piezoceramic composites and materials suited for high-frequency applications. These improvements make the transducers more durable and reliable.

How are ultrasonic piezo transducers used in medical applications?

In the medical field, these transducers are used in patient monitoring systems, ultrasonic imaging, and therapeutic ultrasound. They help in diagnosing and treating various conditions.

What challenges are faced in manufacturing ultrasonic piezo transducers?

Manufacturing challenges include precision engineering, cost-effective production, and quality assurance. Overcoming these challenges is crucial for producing reliable and efficient transducers.